�

�

"If you love life, you will love the Smith Collection Museum of American Speed. Here, there are thousands of

�

physical examples from persons who lived, loved, and had the passion for speed." - "Speedy" Bill Smith

�

BritishV8 Tours: The Speedway Motors Museum of American Speed

��

�

by Curtis Jacobson�

�

Sharing a Passion for Speed

��

BritishV8's seventeenth annual meet was held in Omaha, Nebraska. From Omaha, we enjoyed group outings in�

various directions. One of BritishV8 2013's most exciting and inspirational outings was our tour of�

The Speedway Motors Museum of American Speed in Lincoln. (The museum is transitioning to new name.�

Until recently it was known as "The Smith Collection Museum of American Speed".)�

�

The museum is located on the campus of "Speedy" Bill Smith's company. Speedway Motors is of course a leading�

supplier of high performance parts for street rods and racecars, and Speedway has served those markets for�

over 60 years. The Smith Collection Museum was established in 1992. It's housed in a modern, 135,000ft²,�

three story building. Guided tours are provided by knowledgeable and enthusiastic docents on weekdays at 2pm�

from May through September. Through the balance of the year, tours are given on Fridays only. Large groups�

may be able to make special arrangements. The admission fee is $10/person, but a coupon for free admission�

is given to visitors who spend $20 or more across the parking lot at the Speedway Motors parts counter.�

�

Our BritishV8 group numbered over forty people, so we divided into two subgroups for tours led by Rich Johnston�

and Ray Valasek respectively. Both docents were patient with our questions and generous with their time.�

Our two hour tours were actually about two and a half hours long. The following photos show a very�

small subset of the museum's current display. The museum has much more in storage and in the process of�

restoration. I'm planning to make return visits!�

�

�

Just Inside the Door: Miller Ford!

� �

�

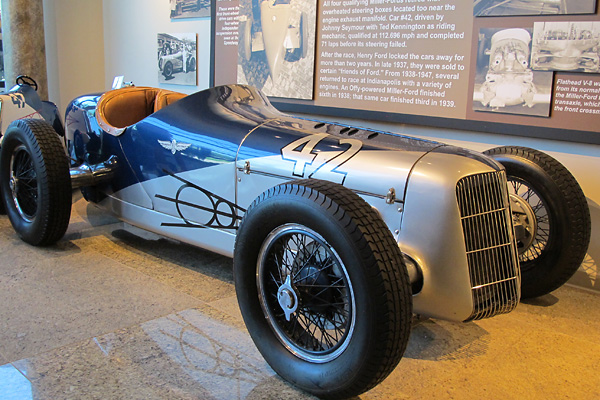

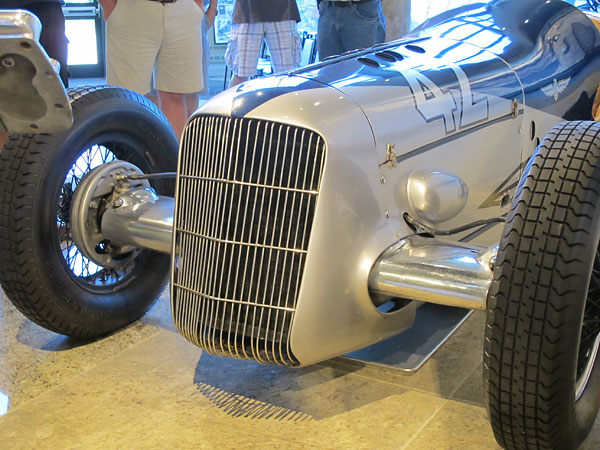

This exceptionally streamlined Miller Ford was designed and built to race in the 1935 Indianapolis 500.

�

Harry Miller had just survived bankruptcy and the loss of his engine business. Then, Preston Tucker

�

came to Miller and suggested approaching Ford Motor Company for sponsorship. Edsel Ford accepted

�

their proposal and agreed to finance a ten car team. However, the deal wasn't finalized until February

�

1935. Five Miller Fords were race-ready in time to qualify for the race. (Shown here: Johnny Seymour

�

and Ted Kennington's #42 Miller Ford which started 27th and finished 24th, retiring after 71 laps.)

�

All ten of the original Miller Ford racecars survive to this day.

�

�

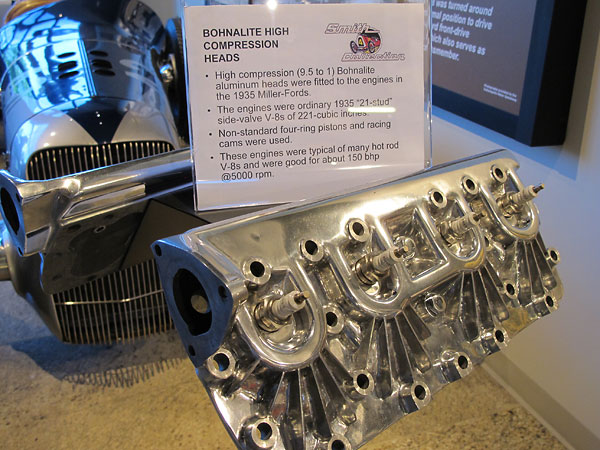

The 1935 Miller Fords utilized Bohnalite high compression aluminum cylinder heads. Even with these

�

heads, the compression ratio was just 9.5:1 and power output was only about 150bhp at 5000rpm.

�

�

Using a production block Ford V8 put the team at a disadvantage, but they believed they could make up

�

the difference with superior aerodynamics. These are front wheel drive cars! Ford's side-valve V8 was

�

turned around backwards and mated to a two-speed transaxle. Eliminating the driveshaft helped Miller

�

get seat height down. Streamlining obscures the fact that these cars featured four wheel independent

�

suspension. Rather than use fairings, upper and lower control arms are sculpted and quarter

�

elliptic leafsprings are nested between them.

�

�

Four Miller Fords qualified and raced in 1935, but all four dropped out due to the same design mistake:

�

steering gears located too close to exhaust manifolds became so hot they bound up. Embarassed by the

�

race results, (Edsel's father) Henry Ford impounded the cars for two years. He ultimately relented and

�

allowed them to be sold. Some raced with Ford engines while others were re-powered with Offenhauser

�

engines. An Offy powered Miller Ford placed 6th in the 1938 Indy 500, and 3rd in '39. One Miller Ford

�

was rebuilt with the first Novi V8 racing engine; it placed 4th in 1941's Indy 500. The Ford powered

�

Miller Ford that Pete Romcevich drove (for Granatelli) in 1947 was historically significant. It was

�

the last production block engine at Indy until 1962 when Buick's aluminum V8 appeared.

�

�

No seatbelts! Race rules stipulated a two person driver/mechanic team. The mechanic braced

�

himself by reaching through a hole in the seat to grab a handle mounted on the chassis.

�

Miller and Offenhauser Racing Engines

� �

�

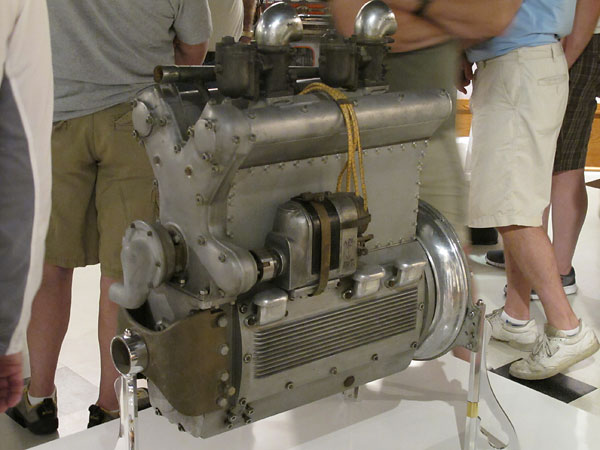

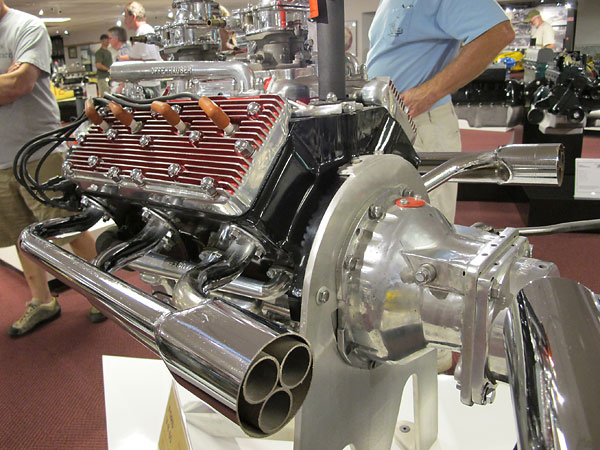

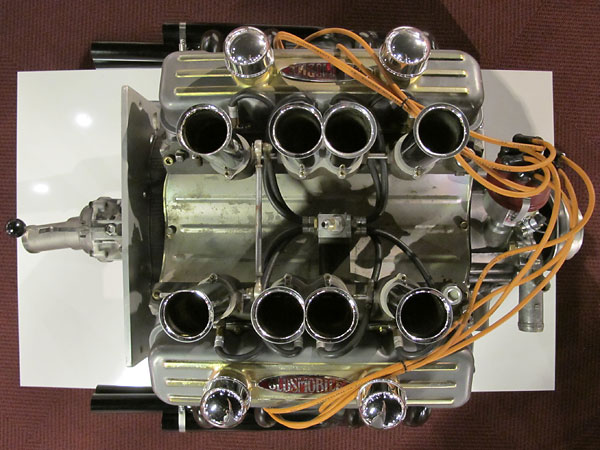

Introduced in 1926, Miller's "91" model (91cid) engine came third in a series of similar designs.

�

Notice that it has four twin-throat updraft carbs of Miller's own design. The 91 was also offered

�

with an optional supercharger. The 183, 122, and 91cid Offenhauser engines won

�

Indianapolis 500 races ten times between 1922 and 1934.

�

�

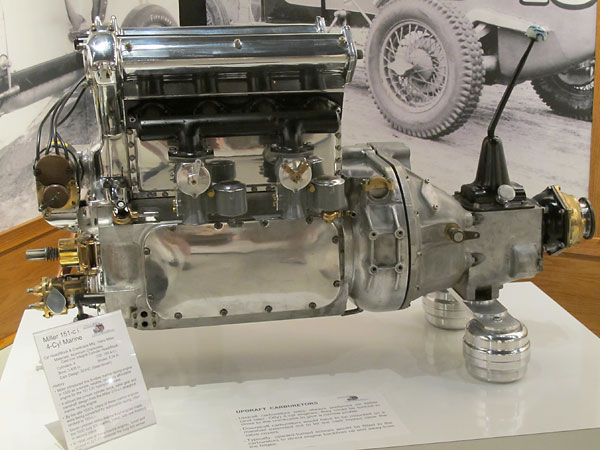

Miller's 151cid "Marine" engine was also introduced in 1926. Many design features were carried

�

over from Miller's 310cid straight eight marine engine. Athough conceived for hydroplane racing,

�

car racers discovered and adopted these engine; often stroking them to 183cid or even 221cid.

�

(These were relatively economical compared to straight eights.) Seven of these engines competed

�

in the 1930 Indianapolis 500, and one finished 2nd. A "220" stroker won the 1934 Indy 500.

�

�

Let's digress for a moment to look at an example of the sort of car that used the Marine engine.

�

This is "The Christie Miller". It was built in 1937 by Floyd "Pop" Dreyer for Lyle Christie.

�

This car had a long career in the Midwest, raced by many drivers, but always owned by Christie.

�

�

Miller engines traditionally featured barrel crankcases. Crankshafts are removed by pulling them

�

out through the rear. Cylinder heads and cylinders were cast as one integral component. (No head

�

gasket to fail!) This particular model was designed by Leo Goossen in late 1930 and early 1931.

�

It features dual overhead camshafts and twin downdraft carbs. Initially, displacement was 200cid

�

(3.875" bore and 4.25" stroke) and this 325# engine was rated 200hp at 6,000 RPM. Before long,

�

Miller began boring these engines to 4.0025" (220cid). They also changed to side intake ports.

�

�

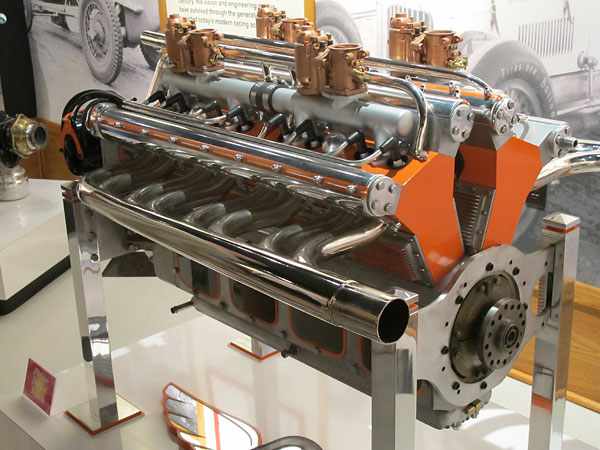

Also designed for Miller by Leo Goossen, Miller's V16 design debuted at Indy in 1931. This is

�

the second Miller V16 built, it was used in 1947's Indy 500. 2.625" bore. 3.125 stroke. 618#.

�

�

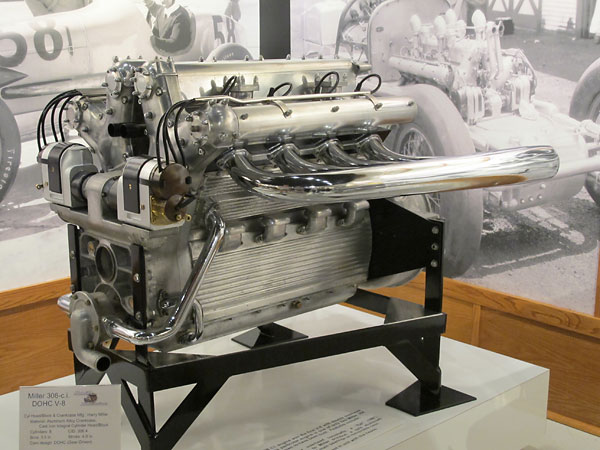

Miller's 308cid DOHC V8 was specifically designed for use in Miller's (two) 1932 four wheel drive

�

Indy Cars. One of these cars won the 1936 AAA Championship. The other traveled to Europe to

�

contest international races. This may be the first V8 to feature dual overhead camshafts. Cylinder

�

banks are arranged in a 45° V, and a flat (180°) crankshaft is used. New to Miller, its split aluminum

�

crankcase features babbitted bearings in removeable caps. Heads/cylinders are cast iron.

�

�

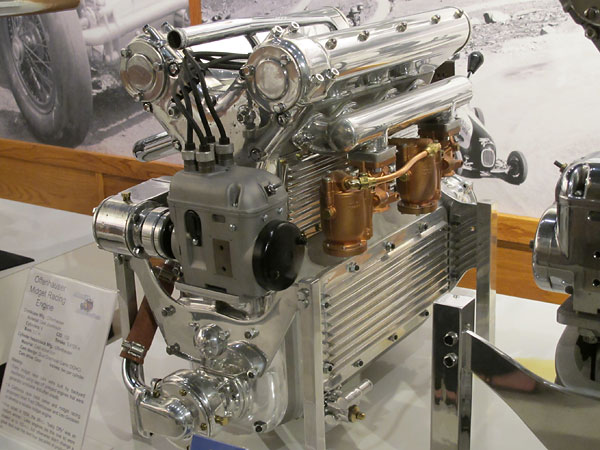

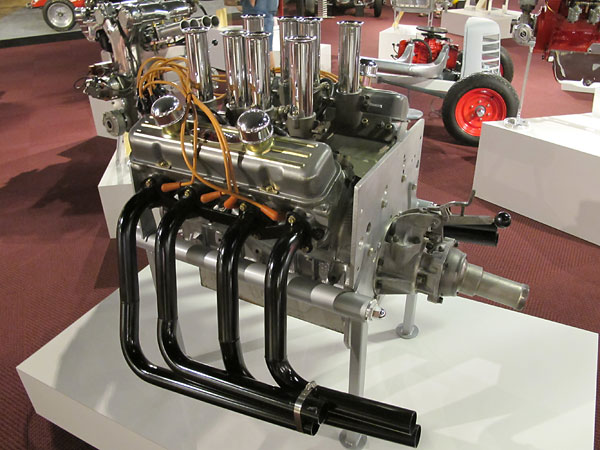

Fred Offenhauser bought out Miller's engine production business in 1934, and began producing

�

engines for Midget racecars. This series of engines started at 98cid, but was soon increased to

�

102cid. (The later version is shown here.) The design was remarkably stable for nearly four

�

decades. Basic specifications: aluminum crankcase with cast nickel iron heads/cylinders,

�

two-valves-per-cylinder, 3.0" bore by 3.6125" stroke.

�

�

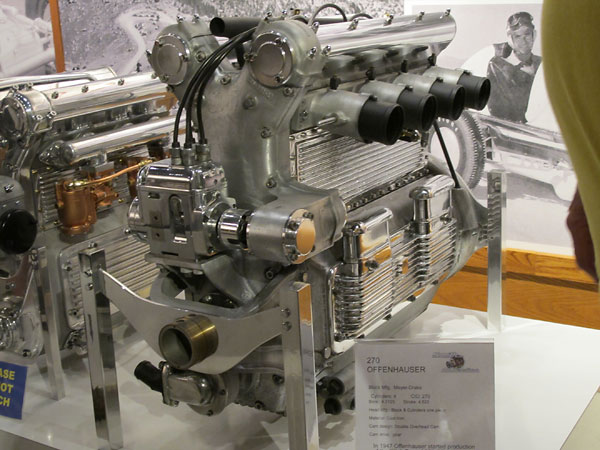

Dale Drake and Lou Meyer bought the Offenhauser engine company in 1946. In 1947, Offenhauser

�

started production of the "high tower" 270cid four cylinder engine. It featured dual overhead cams,

�

four valves per cylinder, five main bearings, 4.3125" bore by 4.625" stroke, and a compression

�

ratio of about 13:1. These engines produced ~415hp and easily revved to 6000rpm. Result?

�

Offenhauser engines completely dominated their chosen racing classes for fifteen years.

�

�

Didn't anyone compete with Offenhauser? J.C. Agajanian paid $225,000 to commission this

�

274cid V8 racing engine. He hired Leo Goossen to design it around a production Studebaker V8

�

engine block, with special machined-steel DOHC heads. A racecar with this engine arrived at the

�

1953 Indy 500, but its team withdrew after their high-torque starter damaged their crankshaft.

�

Diversity in the Midway

��

�

After two seasons of putting their name on American LeMans Series racecars designed and built

�

by Riley and Scott, for the 2002 season Cadillac decided to design and build their own chassis.

�

Yeah, right! Actually, Cadillac's 2002 LMP cars were designed by Nigel Stroud (formerly of March,

�

Hesketh, and Lotus Formula One) and built in Brackley England by Stroud's company: "3GR". This

�

racecar's "Northstar" engine bears no resemblence to the mass-produced engine of the same name.

�

Instead, it's a specially developed version of the Ilmor Indy Racing League engine. Nonetheless,

�

Cadillac LMP "02-002" placed 9th in the 2002 24 Hours of LeMans and 31st at Sebring.

�

�

Ellsworth Lohn founded Eelco Manufacturing Company in 1953 to supply speed parts.

�

Lohn built Wee Eel VI in ~1960 for speed record attempts on the Bonneville Salt Flats.

�

In 1964 a 90cid Coventry Climax engine powered Ellsworth Lohn into the 200mph club.

�

�

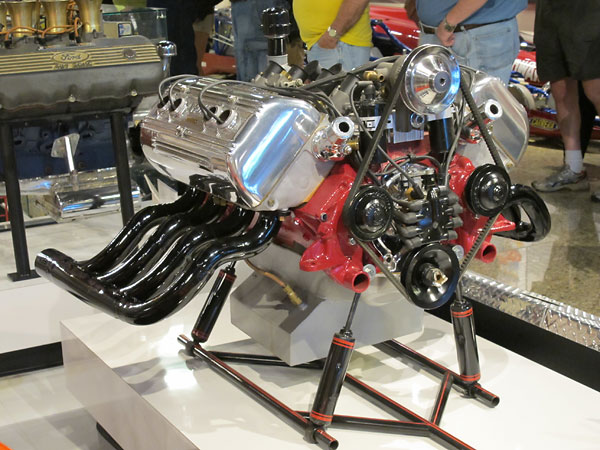

Of all the things Speedy Bill passionately collects, performance upgrades for Ford flatheads

�

must be Number One Priority. His museum includes huge collections of antique pedal cars,

�

lunchboxes, car club plaques, and Buck Rogers stuff but you're never far from yet another

�

flathead Ford. And, where engines are displayed they're usually on nifty custom stands.

�

�

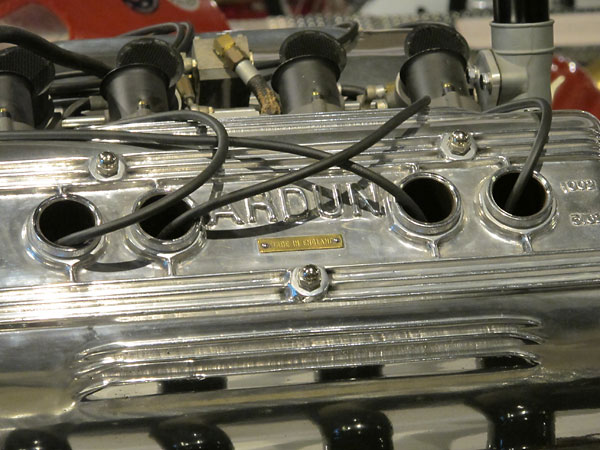

It's a museum of American speed, but international elements can be found throughout. Russian

�

immigrant brothers Zora and Yura Arkus-Duntov initially based their company in New York,

�

but they outsourced production of their famous Ardun cylinder heads to a foundry in England.

�

�

Bob McKee built a 1956 Pontiac stock car like this for racing legend Dewayne "Tiny" Lund. (This

�

reproduction of Lund's car was built by Greg and Bea Schneider of Minnesota.) After stock cars,

�

Bob moved on to more interesting projects. Bob put Buick's brilliant aluminum V8 in the back of a

�

Cooper Monaco racecar for Indy 500 winner Rodger Ward. That project led Bob to development

�

and production of robust transaxles so other racers could follow suit. Before long, Bob was

�

designing and building Can-Am racecars! Read a bit more about Bob here.

�

�

David Pearson's Wood Brothers Racing Mercury Montego with which he won the 1976 Daytona 500.

�

It may have been the most dramatic finish in NASCAR history. King Richard Petty was leading on

�

the last lap. David Pearson passed him cleanly for the lead. Coming through the last corner,

�

Petty retook the lead but didn't get by cleanly. The two cars both spun into the infield.

�

Petty's car stalled out, but Pearson managed to keep his engine running. Pearson's

�

wrecked Montego roared out of the field and across the finish line to victory.

�

�

Lil Gump is a Quarter Midget racecar built by Bruce Bromme for his son in the late 1950s.

�

�

Speedy Bill's own creations. At right, the "4x" sedan exploited a loophole in early 60s rules. Setting

�

the engine back was prohibited, but nothing said you couldn't move the front axle forward. The 4X

�

sedan seemed invincable on short tracks, winning sixteen feature races in a row. Middle: "The

�

Roadster" was built for the 1964 season to compete in the Nebraska Modified Racing Association's

�

new Supermodified class. Note that the engine is offset to the left and the driver to the right.

�

The white car at left is one of three famous "Mechanical Rabbit" roadster style sprint cars

�

which derived from The Roadster. A collaboration of Don Brown and Greg Weld...

�

�

Greg Weld won the 1967 USAC Sprint Car Championship in this Dunseth team Chevy. You

�

might wonder if the paint job is unrealistically immaculate. No. The Dunseth team and racecar

�

builder Paul Leffler in particular were renowned for exceptionally high presentation standards.

�

�

Check out this car's stagger! Wheels and tires of various sizes are positioned to help it get around

�

tight oval tracks. Bob East builds "Beasts" and this one was built it for co-owners George Snider

�

and A.J. Foyt. Davey Hamilton drove this car on paved tracks, whereas Tony Stewart and Snider

�

shared it on dirt tracks. Tony Stewart won his first Silver Crown race victory in this car

�

back in October 1997. (Note: Stewart also won that year's Indycar championship.)

�

�

Nearly all modern Sprint cars feature simple mechanical fuel injection systems and burn methanol

�

instead of gasoline. The four black hoses in this view feed fuel nozzles mounted right in the Brodix

�

aluminum cylinder head. Heat helps with vaporization; placing nozzles low in the airstream helps

�

with airflow. Sprint cars can burn through as much as 30 gallons of methanol in a 30-lap race

�

if too many laps are taken under caution flags. What do they get for that fuel?

�

Their 410 cubic inch engines typically deliver over 800 horsepower.

�

Gasoline Alley

� �

�

Indianapolis Motor Speedway - Home of the 500 Mile Race

�

�

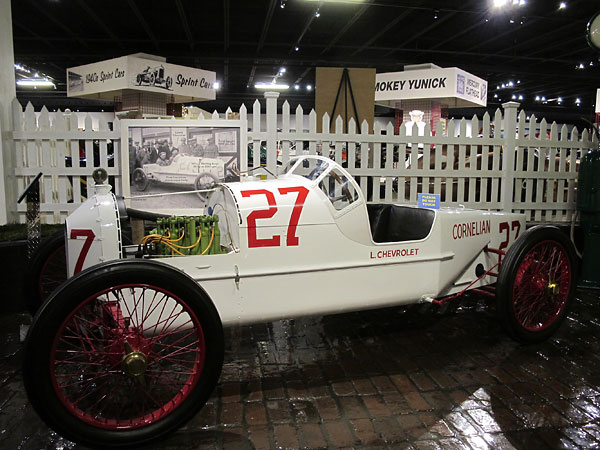

Almost 100 Cornelian automobiles were produced by the Blood Brothers Machine Company of

�

Kalamazoo Michigan. They were advanced cars for their time: monocoque chassis, four wheel

�

independent suspension, rack-and-pinion steering, and a curb weight of less than 1000#.

�

Louis Chevrolet modified and raced a Cornelian in the 1915 Indy 500. He qualified at 81mph

�

and completed 76 laps before an engine failure. Many parts from Chevrolet's Cornelian

�

including his original engine (with broken valve), transmission, and clutch were used

�

in combination with a recreation of his chassis to build this 1914 Cornelian racecar.

�

�

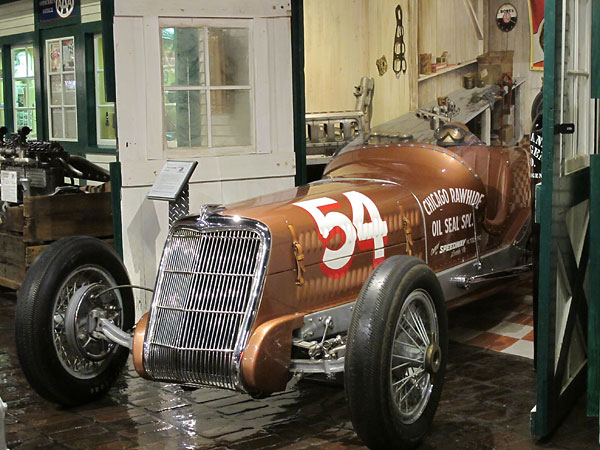

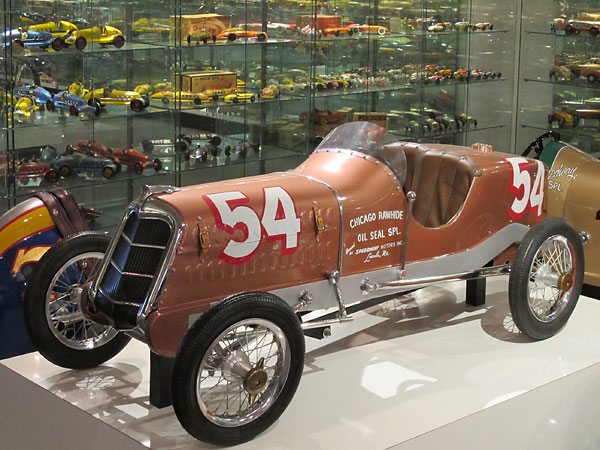

Mark Dees described a similar photo of this car in his book entitled The Miller Dynasty, as follows:

�

"The chassis used by Welch for his blown Offy was pure Ford in origin; it appeared here in 1935

�

when Ardinger failed to qualify it using a hopped-up flathead V-8." For 1937 the car apparently

�

also had a different grille and hood. Herb Ardinger qualified the #54 Chicago Rawhide Oil Seal

�

Special third in 1937 at 121.983mph. He finished 22nd, due to a connecting rod failure.

�

Compare: Vintage Photo of 1937 #54 Chicago Rawhide Oil Seal Special.

�

�

The history of the 500 includes many obscure engines. Charles Voelker of Detroit built this

�

273cid DOHC V12 - an impressive but ill-fated one-off. Although entered in every Indy 500

�

from 1937 through 1949, it only qualified for the big race once. In 1938, Henry Banks started

�

in 31st position and completed 109 of 200 laps before suffering a rod bearing failure.

�

�

Introduced in 1976, the Cosworth DFX was a turbocharged 183cid variant of the Cosworth DFV

�

engine, which had already dominated Formula One racing for eight seasons. DFX powered cars

�

won the Indy 500 ten consecutive years from 1978 to 1987. DFX powered cars also won every

�

USAC and CART championship between 1977 and 1987, taking 153 race victories in the process.

�

Before the Cosworth DFX era ended, these engines were producing over 840 horsepower.

�

�

�

John Judd developed the Judd V8 for the Truesports Team. Bobby Rahal used a Judd V8

�

engine to win the 1988 Pocono 500, but the engine was otherwise unsuccessful.

�

�

The Drake V8 filled in as Offy engines became obsolete in the late 1970s. Making ~570hp at 9500rpm,

�

it was never competitive. Next: the Mercedes 500I was developed by Ilmor for Team Penske to exploit

�

a loophole in Indy 500 rules that opened up in 1991. The loophole was within a rule intended to help

�

low budget teams race with less costly production-based engines such as Buick V6s. Pushrod engines

�

were allowed extra displacement (47.6ci) and turbo boost (10inHG = 4.9psi) The Mercedes engine met

�

the allowance's requirement by having pushrods. With 150-200hp advantage over the rest of the field,

�

the three car Penske team qualified fastest and dominated the 1994 race, eventually lapping the field.

�

(The loophole didn't apply anywhere else. The 500I engine was developed & built for exactly one race.)

�

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

�

On The Road

� �

�

HotRod Magazine "Build Yourself a Street Rod" Cover Car.

�

Speedway sells almost every single part to build a T-bucket style street rod.

�

�

You might remember that Preston Tucker instigated the Miller Ford racecar project we presented

�

at the top of this article. Immediately after World War Two, Preston Tucker created an all-new

�

luxury car company. Although only fifty-one Tucker automobiles were built, the company did create

�

a tremendous splash. Designed by Alex Tremulis, the Tucker "48" featured a flat-six helicopter

�

engine, a Cord transmission, four wheel independent suspension, safety glass all around, and a

�

third headlight, among many other safety features. Note: during development Tucker called this

�

model "Torpedo", but that splashier designation was abandoned before the start of production.

�

�

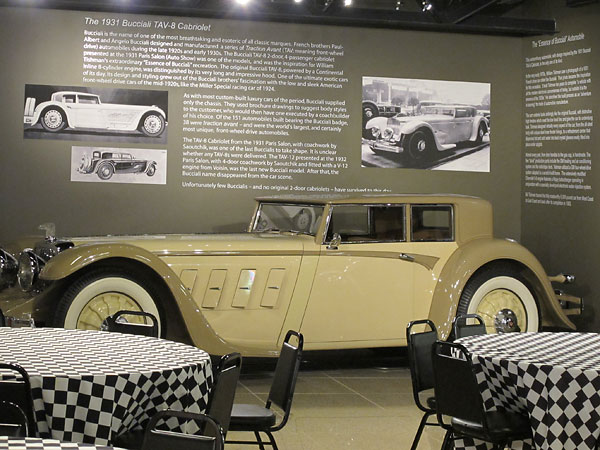

A photo of a Bucciali TAV-8 Cabriolet with body by Saoutchik as presented at the 1931 Paris

�

Motor Show inspired this lovingly built replica by William Tishman. Tishman designed and

�

handmade countless parts of this car. The drivetrain however features a turbocharged Chevy

�

V8 and a General Motors four wheel drive suspension. The original Bucciali was a front

�

wheel drive car. That's what TAV stands for: "Traction Avant" in French. 38 of the 151

�

cars Bucciali produced in their short history were front wheel drive. The long hood was

�

was required to house the car's original Continental inline eight cylinder engine.

�

�

In 1967, Tom Daniel of the Monogram model company designed the Red Baron as a plastic scale

�

model in the T-bucket genre. Released in 1968, it rode the Kookie Kar craze to immense

�

popularity. It wasn't until 1969 that a full scale version of the Red Baron was created

�

by Skyline Customs for the car show circuit, at a cost of ~$10,000.

�

�

The Smith Collection displays a handful of motorcycles with noteworthy engines.

�

This is my favorite: an Ariel "Square Four"! The Birmingham company produced 15,639

�

Square Fours between 1931 and 1958. BritishV8 enthusiasts may recall that the

�

Square Four engine was designed by Edward Turner, who also designed the Daimler V8.

�

Restoration Shop

� �

�

The Smith Collection's restoration and maintenance shop prepares their excellent exhibits.

�

A large machine shop and a warehouse are separately located within the museum building.

�

Over 600 Engines on Display

��

�

Speedy Bill's flathead V8 intake manifold collection. (I count eighty in this photo, but I've been

�

advised that 166 are currently on display and 64 more are in storage.) From the late thirties

�

through the mid fifties, Ford flatheads provided performance to hundreds of thousands of

�

enthusiasts. Ford's flathead V8 provided a foundation for the hot rodding industry.

�

�

Originally conceived for hydroplane racing, Tommy Thickstun of Los Angeles developed splash

�

covers to bolt onto Ford flatheads. Two benefits: besides preventing spark plugs from shorting

�

out, they also suggested the familiar high performance appearance of Ardun-style cylinder heads.

�

�

T. Noah "Tiny" Smith of San Antonio noted that Ford V8-60 engines tended to overheat, so he

�

designed a conversion which relocated exhaust valves into the cylinder heads. (Intake valves

�

remained in their stock location, in the cylinder block.) Smith "Jiggler" air cooled cylinder

�

heads looked cool, but they neither cured the cooling problem nor enhanced power production.

�

�

�

Introduced in 1937 and only offered in the U.S. through 1940, Ford called this scaled-down 136cid

�

flathead V8 the "Sixty" because in factory trim it produced just sixty horsepower. Performance

�

wasn't a priority in its design. Tax laws were. European countries and Britain taxed displacement

�

and bore size respectively. So, you might be excused for wondering why the Smith Collection

�

displays at least a dozen of these motors all gussied up. Midget racing rules were rewritten when

�

these engines became available. The sport's popularity exploded! Speedshops like Speedway

�

Motors found great success by offering parts to improve Ford's export-market economy car engine.

�

�

Two more Ford V8-60 engines. On the left: Offenhauser heads. On the right: Eddie Meyer heads.

�

�

This is an Oldsmobile 215cid aluminum V8, circa 1961-63, fitted with Hilborn fuel injection. (You can

�

tell Oldsmobile and Buick versions apart by their cylinder heads and valve covers. Except for eight

�

drilled/tapped holes, their engine blocks are identical.) These compact and lightweight engines share an

�

exceptionally broad and distinguished history in professional and international racing. The list of teams,

�

drivers, cars, and victories associated with the "215" V8 is extraordinary: Thompson, Gurney, Brabham,

�

Hulme, McLaren, Amon, Matich, Reventlow, Hall, Sharp, McKee, Ward, and Graham Hill just for starters.

�

Exactly one Olds 215 appears in the Smith Collection and it appears without nameplate or description.

�

You might walk right past it. The story of this fascinating marvel of an engine remains largely untold.

�

�

For fifteen years, no stock-block engines had competed in the Indy 500. One year before Jim Clark's

�

Lotus-Ford, Mickey Thompson built a Buick 215 powered rear-engine racecar for the 1962 Indianapolis

�

500 and recruited Dan Gurney to drive it. Gurney qualified 8th of 33 starters with an average speed

�

of 147.886mph. Transaxle failure caused Gurney to drop out of the race after 92 laps, but Gurney

�

showed impressive potential up to that point. He was named Indy's 1962 Rookie of the Year.

�

�

Oldsmobile's 215 is the only stock block American engine to ever win a Grand Prix race. Period.

�

Fitted with special cylinder heads, GM's classic aluminum V8 dominated the 1966 Formula One

�

season. It powered Jack Brabham to championship victory and to four race victories in nine starts,

�

plus two pole positions and one fastest lap. Teammate Denny Hulme scored fastest lap with his

�

Oldsmobile V8 powered racecar at Zandvoort and finished fourth in Drivers Championship points.

�

GM's aluminum V8 delivered Brabham a commanding victory over Ferrari in the Constructors Cup.

�

Hulme's fellow Kiwi, Bruce McLaren, won seven major international races with Olds 215 powered

�

(Zerex Special & McLaren Elva Mk1) sportscars in '64 & '65. Driving for McLaren, Chris Amon won

�

two major races in Olds 215 powered McLaren Elvas. Brabham's fellow Australian Frank Matich

�

used an Olds 215 to win the '66 & '67 Tourist Trophies and to contest the 1967 USRRC Series.

�

�

Thoroughbred vs. draft horse: the Buick/Olds aluminum V8 features an aluminum engine block and

�

cylinder heads whereas a Ford flathead engine is made of iron. Its basic architecture is far more

�

performance oriented: overhead valves vs. sidevalve, five main bearings vs. three, oversquare

�

bore/stroke ratio, 3.5" initial cylinder bore vs. 3.188" bore, etc. The aluminum V8 came from the

�

factory with compression ratios up to 11.0:1, versus just 7.2:1 for the Ford. From 1962, the Olds

�

215 was offered with a turbocharger. One horsepower per cubic inch, straight from the factory!

�

�

If any engine in the Speedway Museum stands out for being ahead of its time, it's probably this

�

Chevrolet. It features detachable crossflow cylinder heads with overhead valves operated by a

�

single centrally located camshaft plus a counterweighted crankshaft. 288cid via a bore of 3.36"

�

and a stroke of 4.00". Chevrolet advertised that this engine produced 55 horsepower... in 1918!

�

�

George Riley of Los Angeles produced this 221cid SOHC V8 engine in 1926. It was rated 175hp.

�

It's the twin of an engine we saw at last year's BritishV8 meet, which was photographed here:

�

Riley V8 at Hatfield Restorations.�

Only three of these engines are believed to have survived.

�

Speedy Bill's Riley V8 features a Graham supercharger.

�

�

Developed to sit atop a Ford Model T engine, the "Akron Hed" was a cast iron cylinder head made by

�

the Williams Foundry of Akron Ohio. Hal Hosterman designed its unique valvetrain in which rows

�

of ball bearings within curved tubes substitute for pushrods and rocker arms. Nearly 2000 of these

�

innovative cylinder heads were made. They were available through various retailers including

�

the Montgomery Ward catalog.

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

Fun for the Family

��

�

The Riverside Special is a Ford powered racecar with Frontenac DOHC cylinder head. Driven mostly

�

by Clyde Gilbert, it raced everywhere west of the Mississippi from Gilbert's home base in Longmont

�

Colorado. (Longmont Colorado is also the home of BritishV8 Magazine, of the ColoRODans hot rod

�

club, and of the excellent Dougherty Museum.) Here's the really amazing thing: the Riverside Special

�

has never once been removed from its unique Frontenac-powered Ford Model T truck since 1934!

�

�

All fifteen models of 1932 Ford are presented here, in standard and deluxe form.

�

An intriguing sign on the rear side of the diorama breaks down Ford's 1932 production

�

in interesting ways. (Did you know Ford bodies were outsourced to various suppliers,

�

including Briggs, Murray, Baker, Raulang, the LeBaron division of Briggs, and Budd?)

�

�

The Smith Collection presents room after room after room of toy cars. I won't pretend

�

that they interest me much... but I do firmly believe people who care about car culture

�

should try to share their enthusiasm with youngsters. Give a kid a ride!

�

�

Chicago Rawhide Oil Seal Special pedal car. (A surprise gift to Speedy from his wife!)

�

�

"Sunbeam Racer" pedal car, possibly inspired by Sunbeam's victory in the 1923 French Grand Prix.

�

�

"Lotus Ford" pedal car, undoubtedly inspired by Jim Clark's Indy 500 racecars. In a green Lotus

�

racecar, Clark finished second in the 1963 Indy 500. Clark won the race in 1965.

�

| �

Did you enjoy this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

Parting Thoughts

� �

�

The Speedway Motors Museum of American Speed is a must-see for anyone interested in

�

American racing and street rod history. Its presentation of early American racecar engineering

�

by Harry Miller and Fred Offenhauser is particularly exceptional. If you're like our BritishV8

�

tour group, you won't want to leave when the tour is over. Go see for yourself!

�

�

�

Disclaimer: This page was researched and written by Curtis Jacobson.�

Views expressed are those of the author, and are provided without warrantee or guarantee.�

Apply at your own risk.�

�

Photos by Curtis Jacobson for BritishV8 Magazine. All rights reserved.�

�

�

�

�