�

�

Calvin Grannis' Chevy LS1 V8 powered 1974 Triumph TR6

� as published in BritishV8 Magazine, Volume XX Issue 1, July 2012�� �

�

Owner: Calvin and Brenda Grannis

�

BritishV8 UserID: 74ls1tr6

�

City: Elk Grove, California

�

Model: 1974 (April) Triumph TR6

�

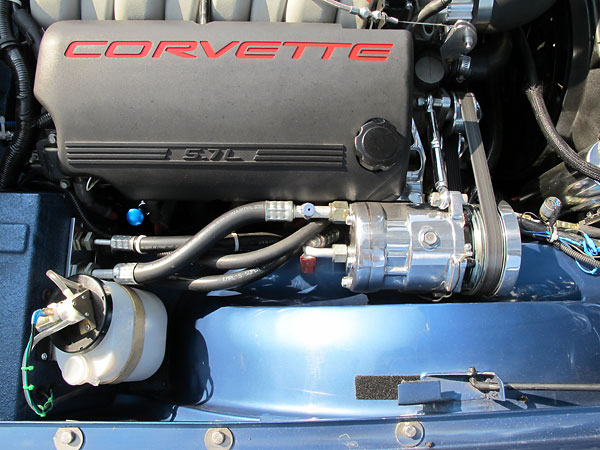

Engine: 2002 Chevrolet LS1 5.7L (EFI)

�

Conversion performed by: owner

�

Today's Triumph

��

Calvin Grannis' interest in British sports cars started in his high school years,�

in the late 1970s, with a 1968 Triumph TR250. The TR250 model was the American-market�

equivalent of Triumph's TR5 model. The two featured similar specs, except the TR250�

came with twin Stromberg carbs in lieu of fuel injection. Those carburetors restricted�

power, and with them the 2.5L six cylinder engine was only rated 111 brake horsepower.�

Calvin wasn't content with that, so he carefully balanced the engine's internals to support�

high RPM use. Next, he boldly shaved the cylinder head an aggressive 0.087" for a dramatic�

increase in compression ratio. Finally, he put the engine together with triple Weber carburetors.�

The combined effect was a Triumph that could keep up with almost any stock Mustang or Camaro�

to the edge of town, then outbrake and pass them in the twisties. A fancy highly-polished�

lacquer paint job completed the project. �

�

Fast forward to 2007, when Calvin discovered the BritishV8 website and its message board.�

Calvin says our website inspired him to build another Triumph: similar fun, but updated to�

meet all of today's performance expectations. Smooth. Comfortable. Confidence inspiring.�

Calvin chose to use a Chevrolet LS1 engine and a T56 six speed transmission from a 2002�

Chevrolet Camaro Z28, but he didn't stop there. His 1974 Triumph TR6 represents a complete�

and coherent vision. It seems that every aspect of the car has been updated, and that a�

careful balance has been struck. No single thing stands out as "too much." �

�

The most understated thing about Calvin's TR6 is its exterior bodywork. Its "ghost stripes"�

are so subtle that from some angles you might wonder if you're imagining them. You might�

or might not notice the whopping huge dual Monza glass-pack exhaust tips that peak out�

from under the Kamm tail. You might just barely catch a glimpse of the Wilwood brake calipers�

through the wheels. Okay... I'll concede that the seventeen inch wheels would be hard�

for anyone to miss, but they're obviously Minilite inspired. Wrapped around all that though,�

I'd challenge any casual observer to identify a detail of the exterior sheetmetal that doesn't�

look bone stock. My personal impression is that this car is nothing if not subtle.�

�

Until someone pushes the loud pedal to the floor! As the car accelerates, the skin of your�

face gets really tight against your cheekbones. The skin behind your ears starts to flap�

excitedly in the wind. Fighting such great g-force, you can't keep your mouth closed. I've�

been in cars that made me smile, but never in this particular way. (Meanwhile, I was�

thinking: "Uh. Ummm. Calvin? I forgot my helmet...")�

�

Calvin and Brenda celebrated the triumphant completion of their project by making the �

2000 mile round-trip trek to attend BritishV8 2012, and that's where I got to experience�

their LS1 powered TR6 in person. Four hundred brake horsepower in a Triumph TR6 is indeed�

impressive. But Calvin Grannis is as cool as a cucumber. He thinks he's just tooling around.�

This is a Sunday drive to him, and we're taking things easy. Indeed we are. But Standards�

have changed. This isn't yesteryear's hot-rod - it's faster but it's much more refined - it's�

Today's Triumph.�

�

Features and Specifications

�| Engine: | �Chevrolet LS1 V8 engine from a 2002 Camaro Z28.�

(The engine came standard with aluminum block and cylinder heads,�

electronic fuel injection,�

coil-on-plug electronic ignition,�

and six-bolt main bearing caps.�

5.7L equals 346ci.)�

Texas Speed & Performance (TSP) / Precision Race Components (PRC) LS6-style cylinder heads.�

62cc combustion chambers.�

10.8:1 static compression ratio.�

CNC-ported and fitted with oversized valves (2.02" intake and 1.575" exhaust).�

Dual 0.650" lift valve springs.�

Chromaloy push rods.�

LS2 timing chain and gears.�

FAST 90mm intake, hand ported by Tony Mamo from AFR.�

90mm throttle body from Nick Williams.�

K&N gauze air filter.�

Ported LS6 oil pump.�

Stock 28# fuel injectors (for now).�

TSP-sourced Comp Cams camshaft (228° duration, 0.588" lift, 112° lobe separation angle.)�

Stock rocker arms with Comp Cams sealed-needle bearing trunion upgrade.�

LS7 lifters.�

Stock PCM, tuned with HP Tuners software.�

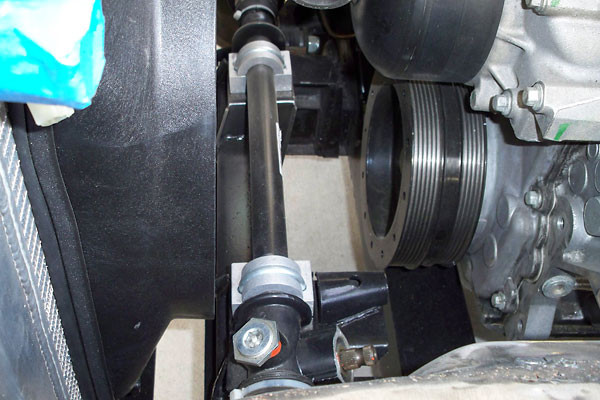

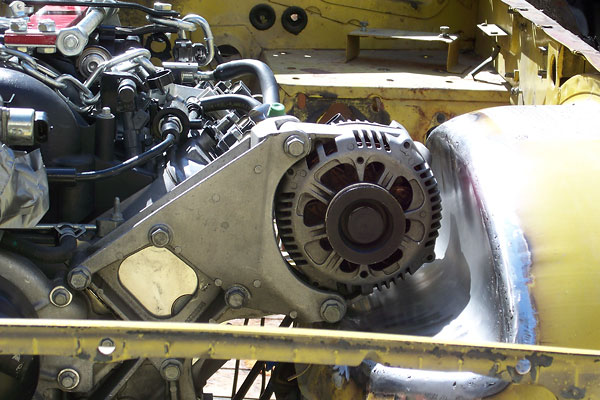

Street & Performance Front Runner accessory bracket / pulley / serpentine belt drive system.�

| �

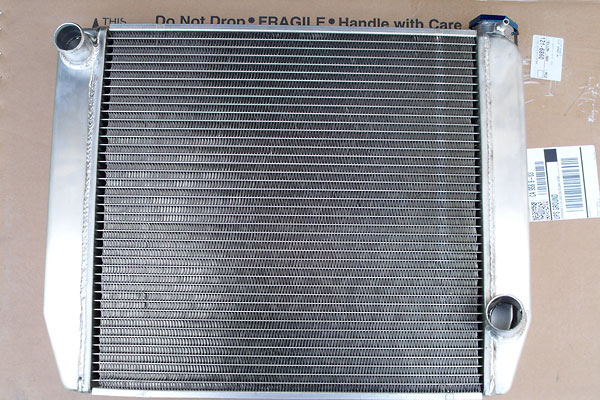

| Cooling: | �Griffin aluminum crossflow radiator (24" x 19" x 3") with 2-row (1.25" tube) core.�

16" 2250cfm electric fan with matching shroud. | �

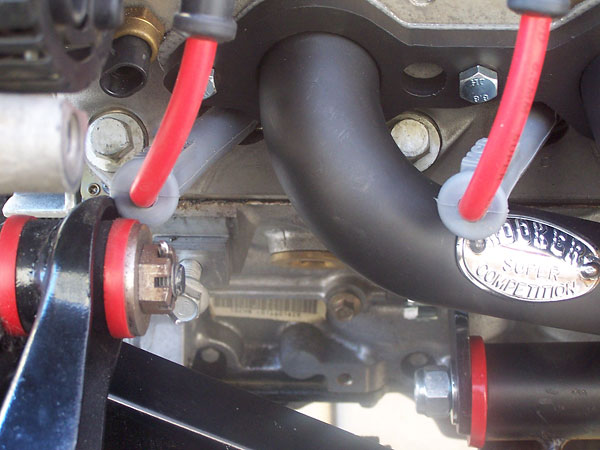

| Exhaust: | �Hooker Super Competition four-into-one headers with 1.625" diameter primaries.�

2.5" pipes.�

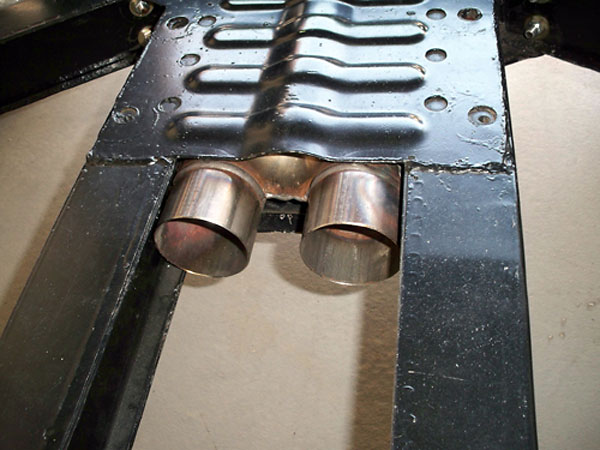

Magnaflow X-pipe mounted inside the frame.�

Dual 2.5" Borla Pro XS mufflers.�

Monza 2.5"-to-4" glass-pack exhaust tips. | �

| Transmission: | �Tremec T56 6-speed with normal F-body gearing.�

(6th gear: 1700rpm at 70mph & 2000rpm at 80mph. Great for gas mileage!)�

Fidanza 12.5 pound aluminum flywheel with changable clutch surface.�

SPEC Stage 2+ pressure plate and clutch disc.�

Stock TR6 master cylinder.�

Stainless steel braided line.�

Chevy Camaro 3" aluminum prop shaft, shortened to 25".�

(Camaro-spec U-joint at transmission. Nissan Infiniti Q45 U-joint at differential.)�

Street & Performance Inc. gear shifter ("shifter handle relocator").�

Ford Mustang shifter knob, reamed out to fit. | �

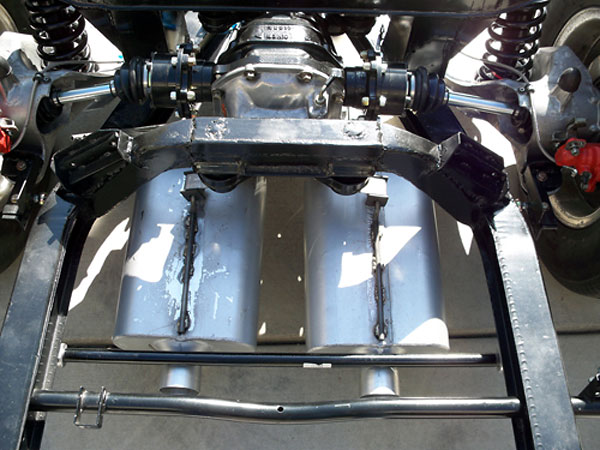

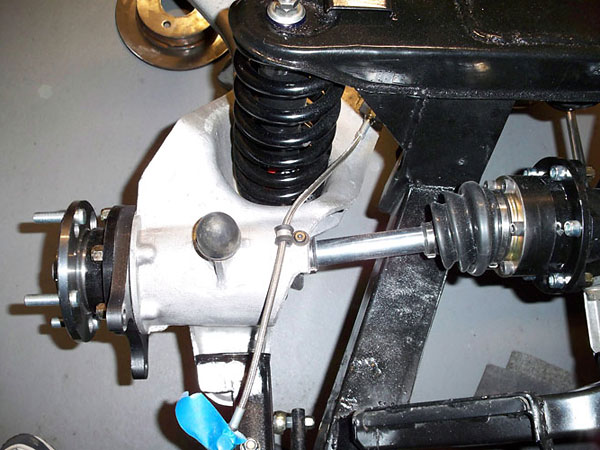

| Rear End: | �Nissan Infiniti Q45 (R200) viscous limited-slip differential and 3.54:1 final drive ratio.�

Good Parts constant velocity joint axles and uprated hubs. | �

| Front Suspension: | �quick ratio steering rack.�

Woodward Precision Power Steering universal joints.�

Uncle Jack's uprated spindles.�

Good Parts lowering springs.�

Spax adjustable shock absorbers.�

Nylatron bushings.�

Good Parts anti-sway bar. | �

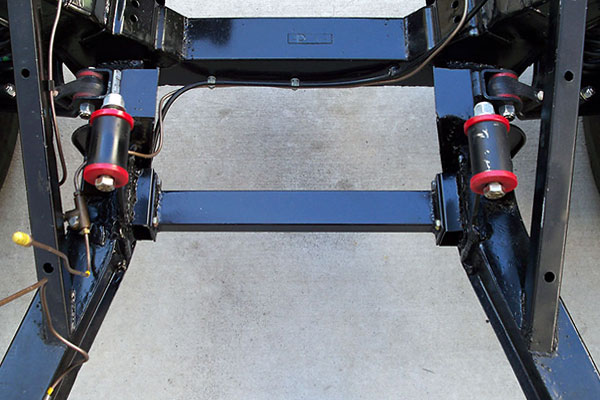

| Rear Suspension: | �Good Parts 600#/inch lowering springs.�

Roadster Factory coilover conversion kit, featuring AVO shock absorbers.�

Good Parts adjustable anti-sway bar, re-located rearward.�

Good Parts adjustable trailing arm attachment brackets and Nylatron bushings.�

Rear trailing arms upgraded from 5/16" to 3/8" studs, with Helicoil inserts.�

| �

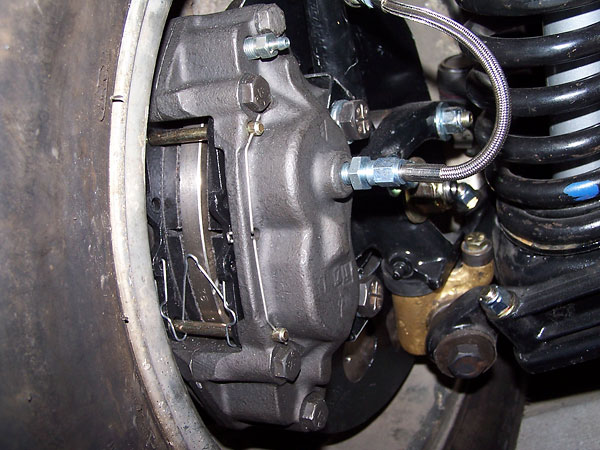

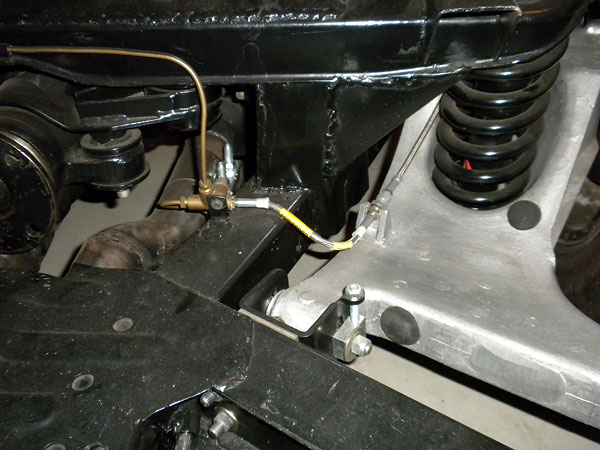

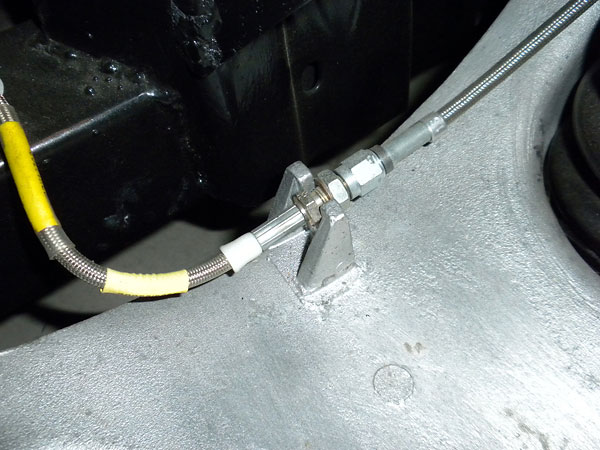

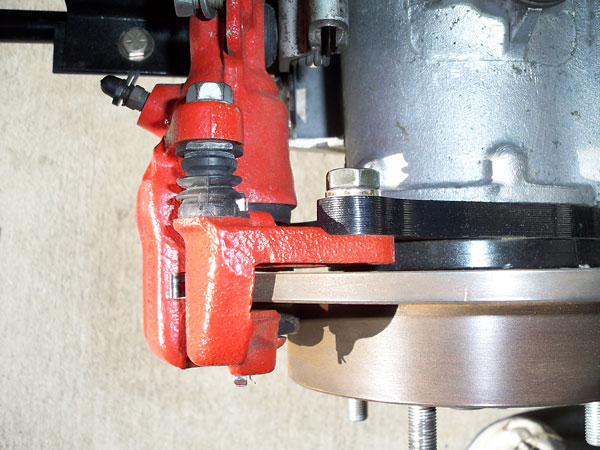

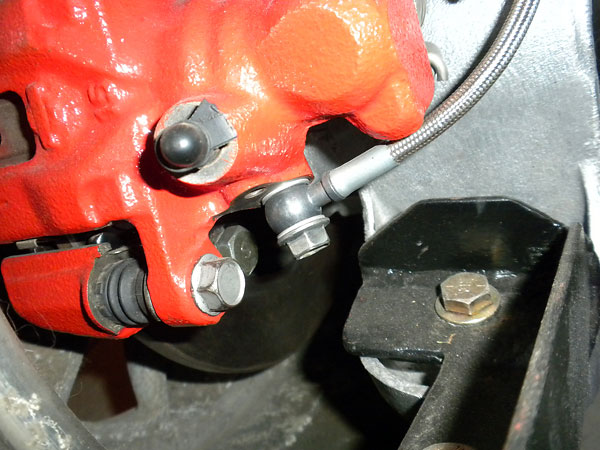

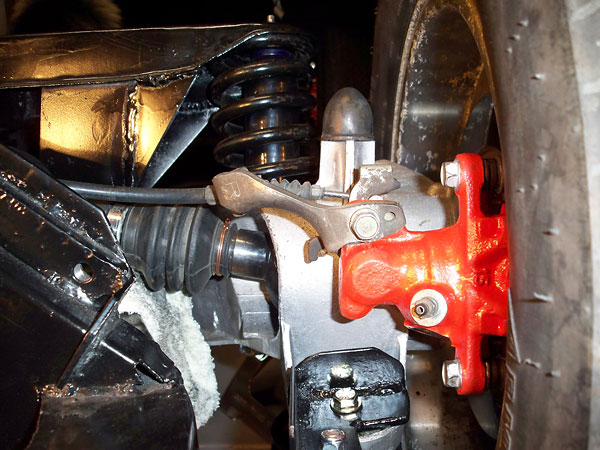

| Brakes: | �(master) Wilwood 1.125" tandem master cylinder. Wilwood proportioning valve on rear circuit. � (front) Wilwood 4-pot calipers and 12.19" rotors. Custom aluminum hats. Stainless braided lines. � (rear) '97 Nissan Maxima calipers on Don Watson brackets. '92 Nissan 240SX rotors and e-brake cables. | �

| Wheels/Tires: | �Rota RB Hyper Black aluminum wheels (17x7.5, 4-100mm lug spacing, +45mm offset).�

Yokohama S-drive w-rated 245/45R17 tires (~10" wide).�

One inch spacers/adapters to convert from 4-4.25 hubs to 4-100mm wheels. | �

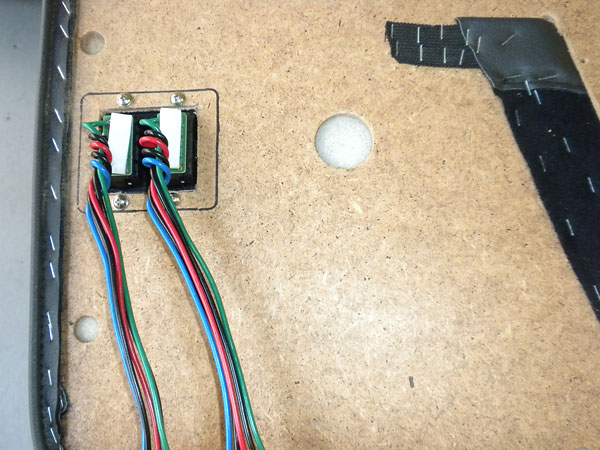

| Electrical: | �Advance Auto-Wire wiring harness.�

Stinger distribution block and main fuse.�

Odyssey Extreme Racing (ER40, nine pound) battery, mounted in trunk.�

140 amp Delco style alternator, with polished finish.�

LED rear running and brake lights. | �

| Interior Mods: | �custom dashboard made from Kewazinga African rosewood by Randy Keller / Prestige Autowood.�

AutoMeter Phantom II digital gauges (set of 7).�

Leather wrapped Moto-Lita steering wheel. �

Early-style Mazda Miata seats, with upgraded speakers in headrests.�

Upper and lower electric seat heaters.�

SPAL power windows, installed with four-pin contact strips at door jams.�

Vintage Air Mini Air/Heat/Defrost, with controls in center panel.�

(Sanden 508 a/c compressor.)�

LED footbox lighting, both sides.�

Wool carpet. | �

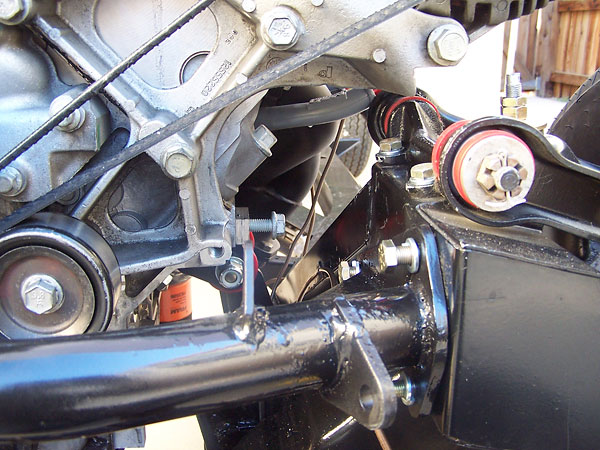

| Chassis Mods: | �welded metal plate in front lower suspension attachment areas.�

Plates were welded-in on top of frame under outer footwell area.�

1" steel tube welded in between frame rails by the transmission mount.�

Re-welded transmission mounting area for enhanced strength.�

Added reinforcement around rear suspension area (i.e. both tower sections.)�

Tied both rear suspension towers together with 1" steel tube.�

Moved front sway bar to above skid pan and extended front frame to strengthen sway bar attachment points.�

| �

| Body Mods: | �no sheetmetal modifications on the outside of the car.�

PPG Atlantic Pearl Blue two stage paint with white pearl ghost stripes.�

Lizard Skin sound and heat control products. | �

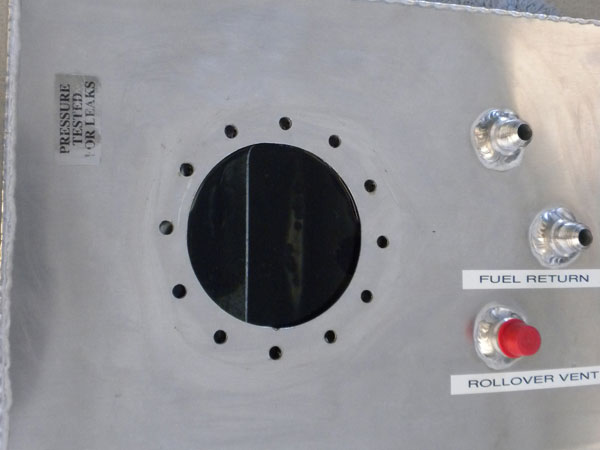

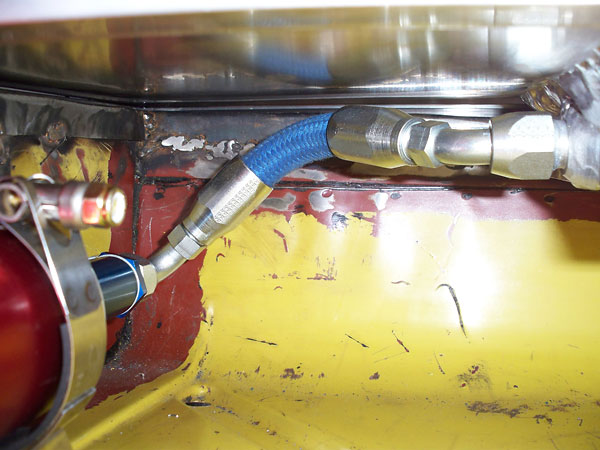

| Fuel System: | �Racers Choice Inc. 19 gallon aluminum fuel tank.�

Aeromotive inline fuel pump.�

Corvette fuel filter / regulator. | �

| Performance: | �28mpg highway, 25mph city.�

0 to 60 in ~3.5s.�

~408 horsepower from 5800 through 6100rpm and�

~390ft-lbs torque from 4500 through 5200rpm�

at the wheels. | �

| Completed: | �road-worthy in April 2011. (First engine start on June 17, 2009.) | �

Engine Installation

��

�

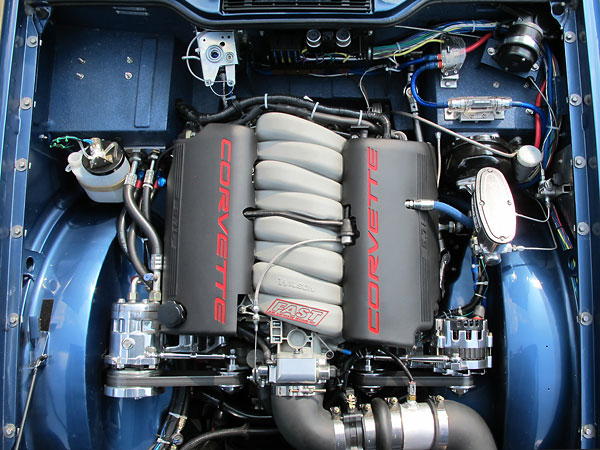

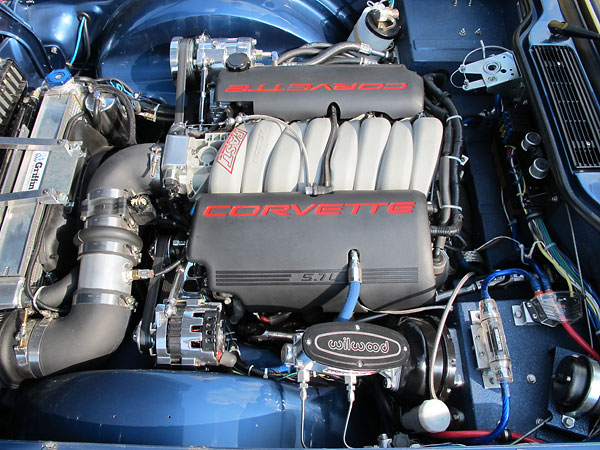

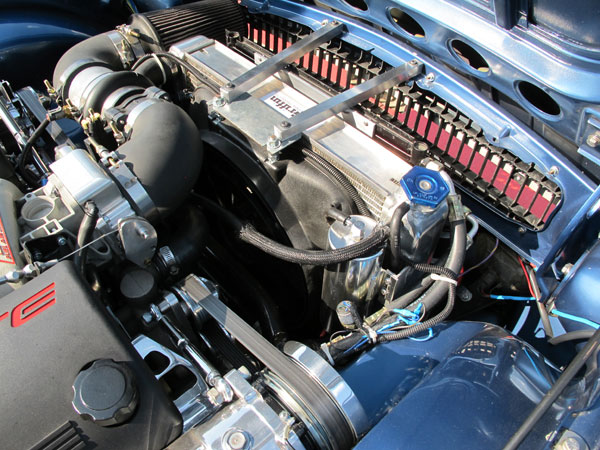

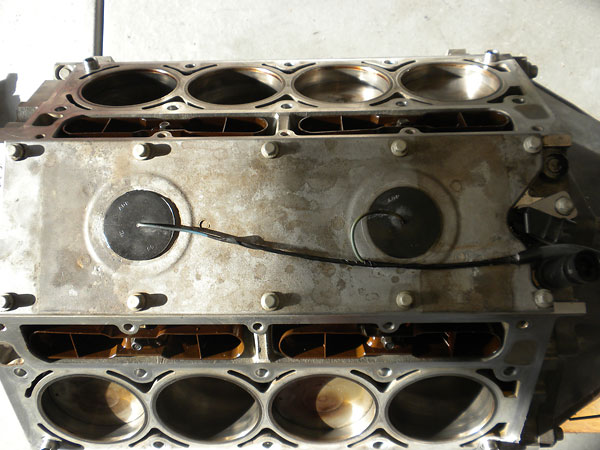

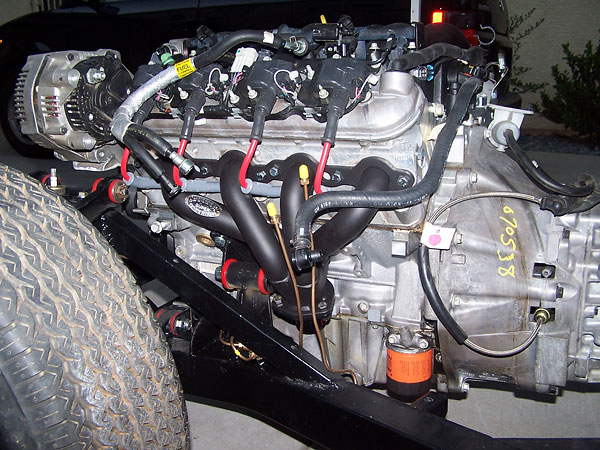

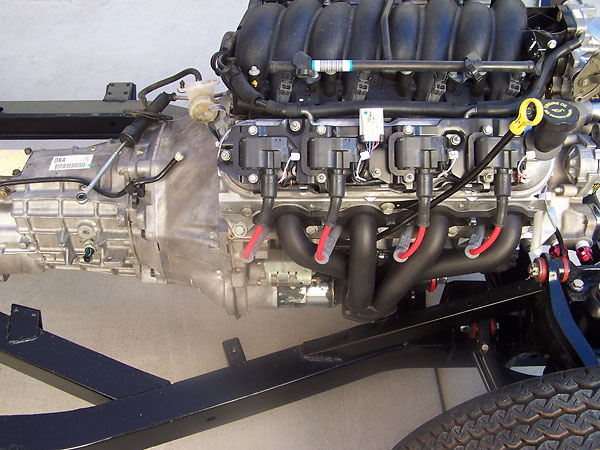

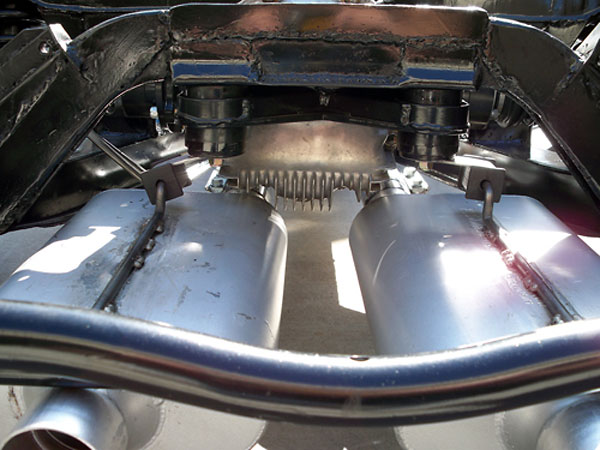

Chevrolet LS1 V8 engine: 350 cubic inches, aluminum engine block and cylinder heads,

�

six-bolt main bearing caps, electronic fuel injection, and coil-on-plug ignition.

�

�

At the wheels? 408 horsepower from 5800 to 6100rpm. 390ft-lbs from 4500 to 5200rpm.

�

�

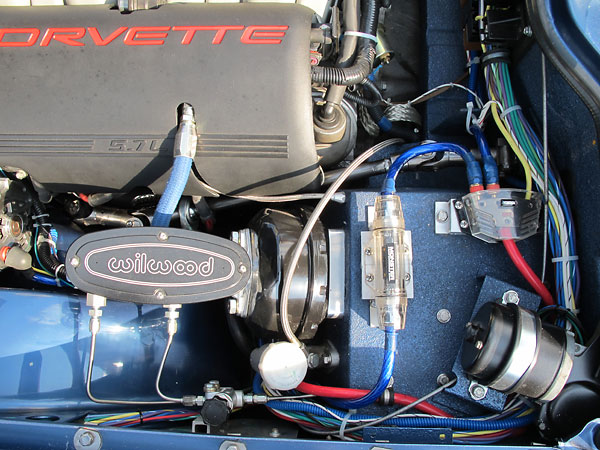

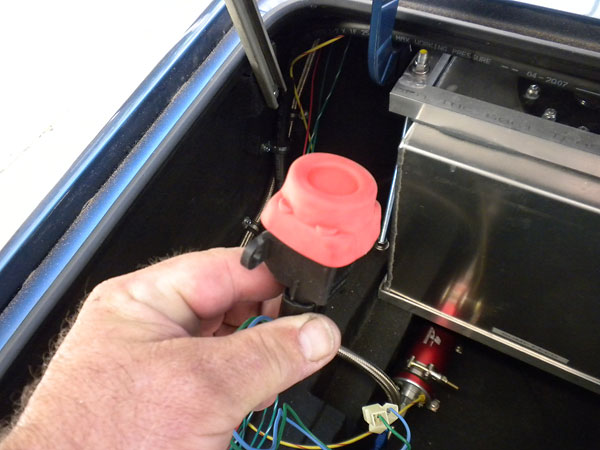

Stinger distribution block and main fuse.

�

�

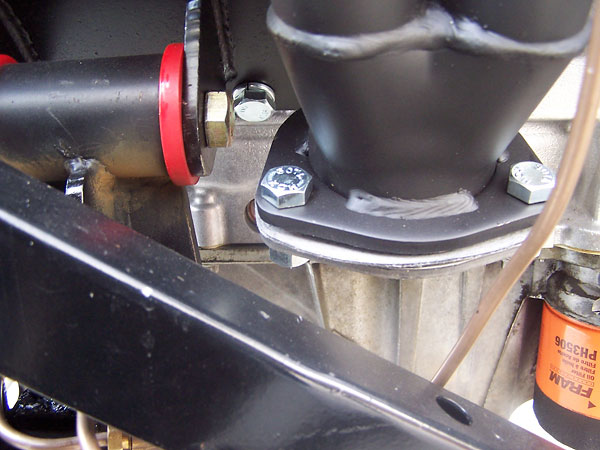

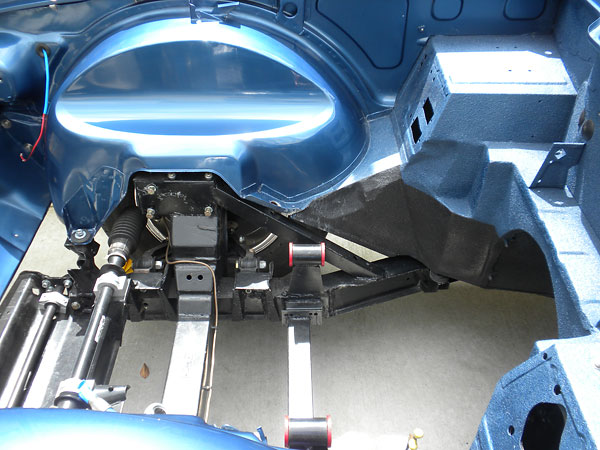

Wilwood 1.125" bore tandem brake master cylinder.

�

�

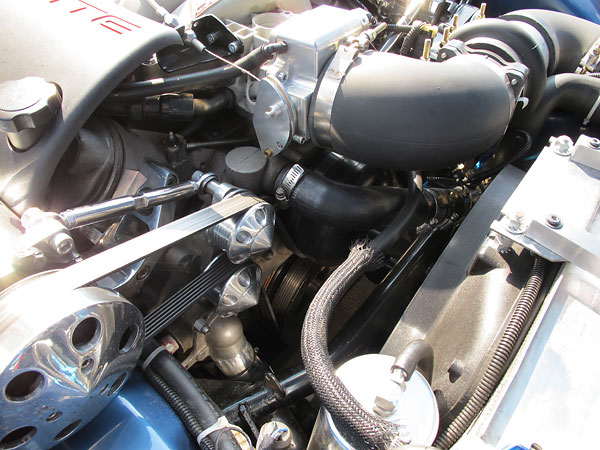

Woodward Precision Power Steering universal joints.

�

�

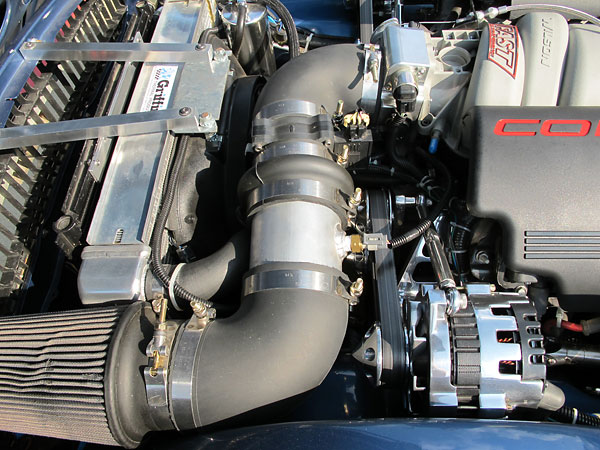

FAST 90mm intake, hand ported by Tony Mamo from AFR.

�

�

K&N gauze air filter, intake air temperature sensor, and mass airflow sensor.

�

�

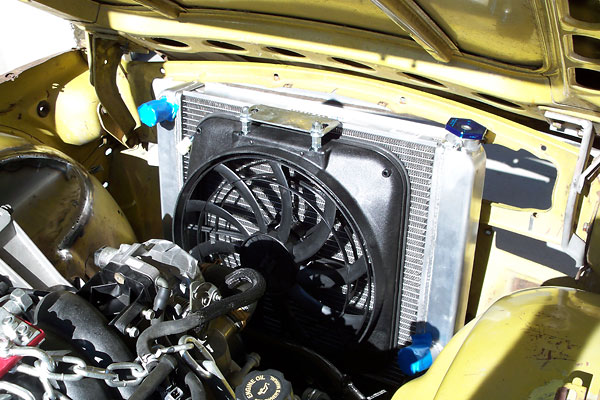

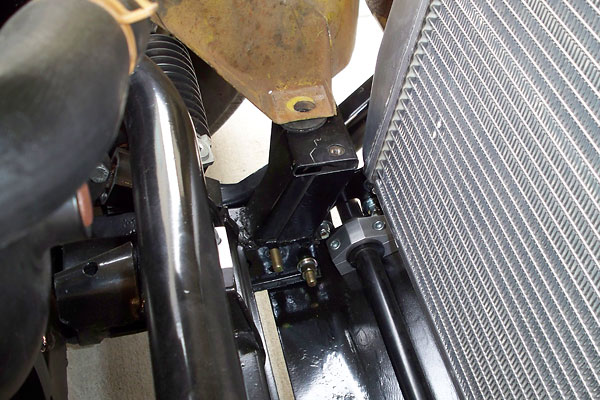

Custom aluminum brackets secure the radiator and AC condenser.

�

�

Street & Performance Front Runner accessory bracket / pulley / serpentine belt drive system.

�

�

Sanden 508 air conditioning compressor.

�

�

Advance Auto-Wire fuse and relay block.

�

�

�

19 gallon fabricated aluminum fuel tank.

�

�

Left: Corvette fuel filter and regulator (1999-2004). Right: Aeromotive inline fuel pump.

�

�

This vacuum pump is connected to the power brake booster. It provides 20psi of vacuum regardless

�

of engine load and speed. With its own inline pressure switch, it only runs when needed.

�

�

Odyssey Extreme Racing (ER40, nine pound) battery, mounted in trunk.

�

How It Was Done

�Engine Build

��

�

Chevrolet LS1 V8 engine from a 2002 Camaro Z28.

�

�

This engine came standard with aluminum block and cylinder heads, electronic fuel injection,

�

coil-on-plug electronic ignition, and six-bolt main bearing caps.

�

�

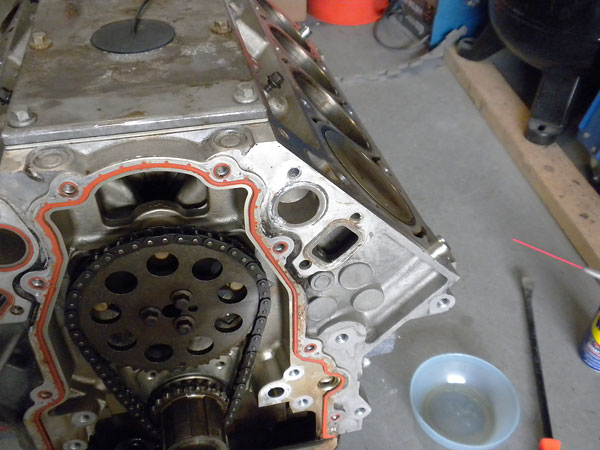

Modern gaskets that don't leak are one of the subtle charms of the LS1 engine.

�

�

These holes are where roller lifters go, but if you look ahead one photo you'll see the top of

�

nifty plastic guides (sometimes called "trays") that get inserted here too. The guides keep

�

the axis of the rollers parallel to the camshaft bore. Surprisingly, they grip the lifters

�

just firmly enough to facilitate heads-on camshaft swaps.

�

�

Twin knock sensors mounted on the LS1 valley cover.

�

�

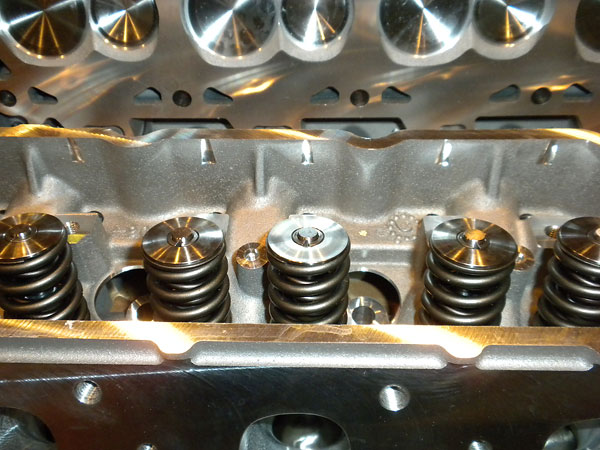

Texas Speed & Performance (TSP) / Precision Race Components (PRC) LS6-style cylinder heads.

�

�

Oversized valves: 2.02" intake and 1.575" exhaust.

�

62cc combustion chambers for a 10.8:1 static compression ratio.

�

�

Dual 0.650" lift valve springs.

�

�

The cylinder head porting was done automatically with a CNC milling machine.

�

They call this shape "cathedral ported".

�

�

Some LS heads have round exhaust ports. The versions with D-shaped exhaust ports flow better.

�

�

ARP cylinder head bolts. (These are re-usable whereas the OEM bolts were for one-time-use.)

�

�

Rockers (top of photo, ready to be installed) mount on individual rocker stands (middle of photo).

�

�

Timing cover and crankshaft pulley installed.

�

�

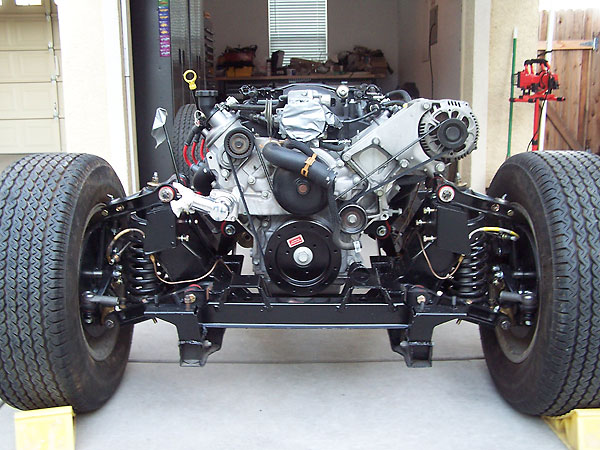

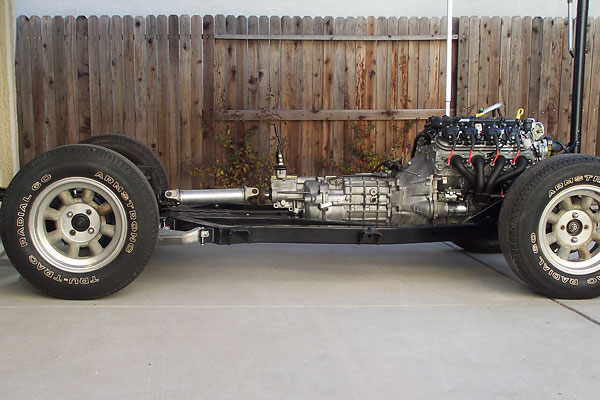

This is just one of many trial installations of the LS1 engine into Calvin's TR6 chassis.

�

�

Driver side exhaust header installation. (No problem here.)

�

�

Passenger side header installation. (A little too tight for comfort. Changes shown below.)

�

Cooling System

��

�

Griffin aluminum crossflow radiator (24" x 19" x 3") with 2-row (1.25" tube) core.

�

�

Sixteen inch 2250cfm electric fan with matching shroud.

�

�

Stock thermostat housing rotated counter-clockwise ninety degrees to point downward.

�

The standard coolant thermostat for LS-series engines opens at 195°F.

�

�

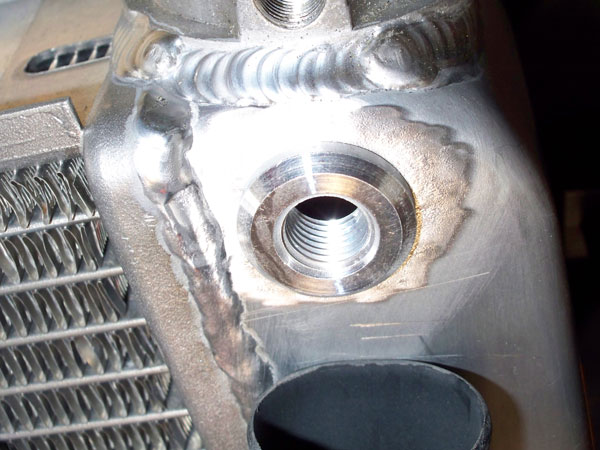

1/4" NPT threaded aluminum bung installed on the radiator to vent out trapped air.

�

�

On an LS1, the radiator's steam vent can be plumbed to the warmer system on the throttle body. (Plumbing

�

to a header tank would be another good option.) Also shown: the hose barb at the pressure relief cap.

�

�

Replaced lower radiator port.

�

�

Radiator mounting bracket.

�

�

Custom stainless steel tube for the lower coolant line.

�

�

Lower coolant plumbing will go here.

�

Exhaust System

��

�

Hooker Super Competition four-into-one exhaust headers.

�

�

The driver-side exhaust header fit pretty well right out of the box.

�

�

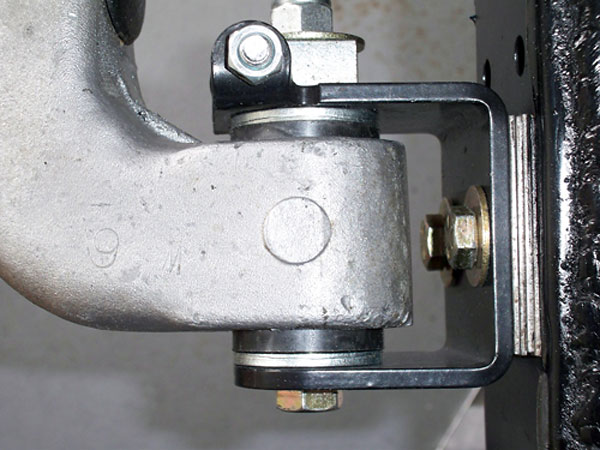

On the passenger-side, the exhaust header was nearly touching the motor mount and also

�

uncomfortably close to the starter motor, so Calvin decided to extend the header's

�

lower flange downward by about two inches. At left: oxygen sensor.

�

�

Routing exhaust below the frame would seriously compromise ground clearance, so Calvin was

�

compelled to engineer a through-the-frame system. For convenient service, from here back

�

just six stainless steel band clamps hold the exhaust system together

�

�

Magnaflow X-pipe.

�

�

The X-pipe is tucked into the narrow "t-shirt" section of the Triumph TR6 frame. This is

�

as physically close as Calvin could get the X-pipe to the headers.

�

�

The mufflers shown on this page are FlowMaster 40s, but Calvin took those off pretty soon after

�

the car was roadworthy because they were too loud. He replaced the FlowMasters with Borla Pro XS

�

stainless steel mufflers (mounted similarly.) The Borla mufflers are slightly longer and heavier.

�

�

Mounted on rubber hangers, the mufflers don't transfer vibration directly into the body.

�

Transmission, Clutch, Shifter, Etc.

� �

�

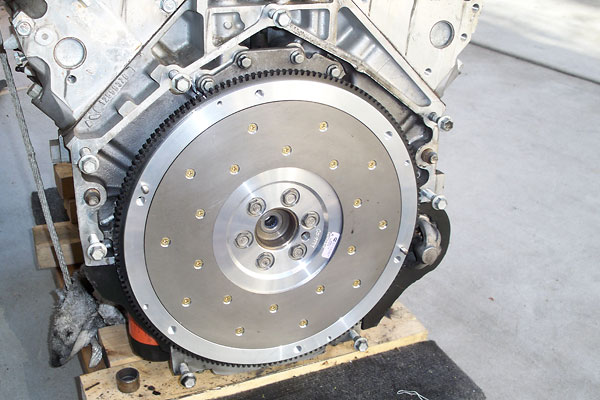

Fidanza 12.5 pound aluminum flywheel with changable clutch surface.

�

�

SPEC Stage 2+ pressure plate.

�

�

SPEC clutch disc. This clutch/pressure plate combination should be good for ~625 foot pounds of torque.

�

�

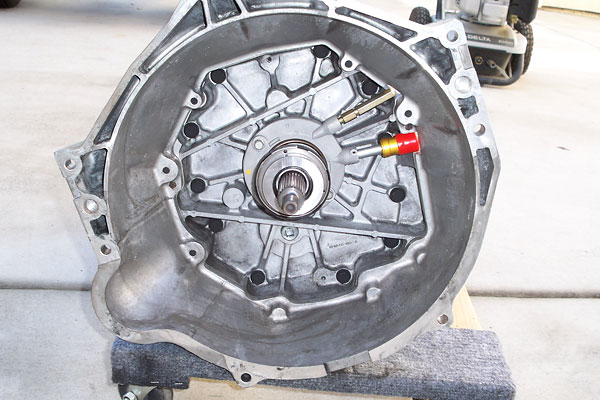

LS1/T56 bellhousing, including annular clutch slave cylinder.

�

(Also known as a "hydraulic throw-out bearing".)

�

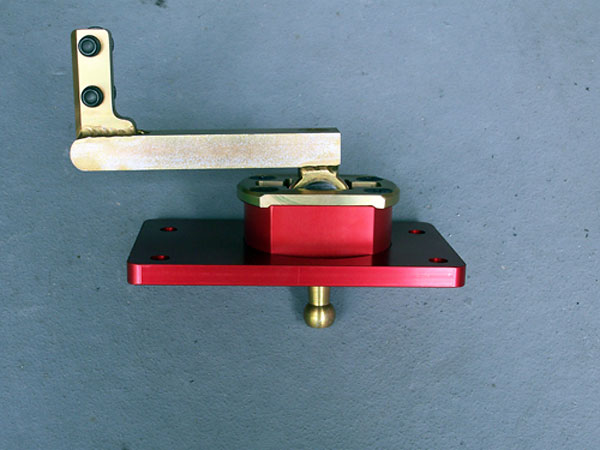

�

Street & Performance Inc. gear shifter.

�

(That company markets this shifter as a "shifter handle relocator.)

�

�

Original Triumph TR6 dash support, stripped down to bare aluminum and then cut

�

and extended 4.5" rearward. The special gear shifter extends forward to meet it.

�

�

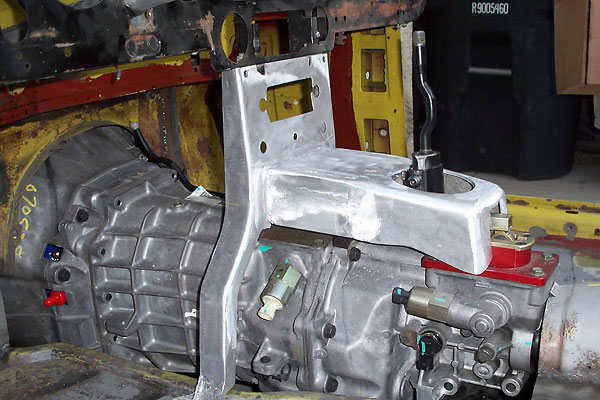

Tremec T56 6-speed with normal GM F-body gearing. Not lightweight and not compact...

�

but it has its virtues, including two overdrive gears. (Great for fuel economy!)

�

�

The original driveshaft tunnel has been cut out and reinstalled about two inches higher.

�

�

The parking brake lever had to be shifter rearward (3.5").

�

�

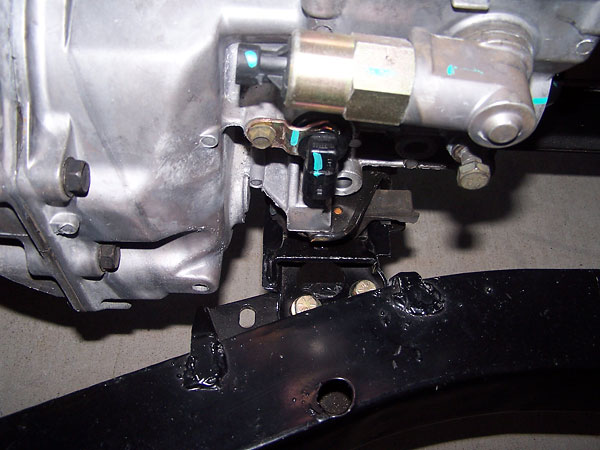

The T56's bulky reverse gear lockout solenoid. Near the end of the build, after the car

�

had been test driven multiple times, Calvin decided this solenoid stuck out too far.

�

He removed it and substituted a cap with a heavy spring and plunger. Reverse can be

�

engaged while moving forward, but it will take a little muscle.

�

�

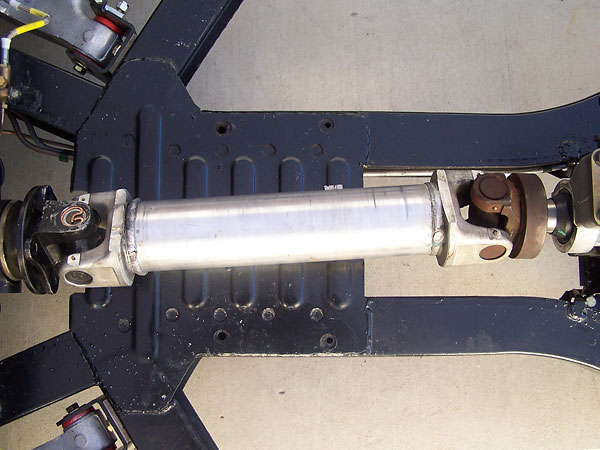

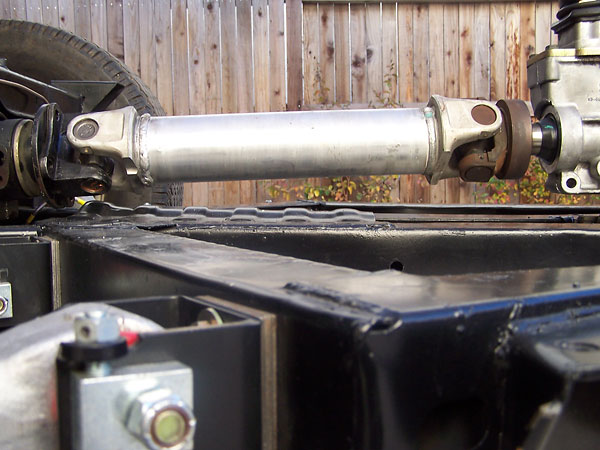

Chevy Camaro 3" aluminum prop shaft, shortened to 25".

�

�

Nissan Infiniti Q45 U-joint at the differential. Camaro-spec U-joint at the transmission.

�

Fuel System

��

�

Racers Choice 19 gallon aluminum fuel tank (12" x 12" x 30"). Calvin cut open one side of

�

the tank, inserted baffles, TIG welded them into place, and welded the exterior back up.

�

�

A stock Triumph TR6 fuel filler connects to a 2" inside diameter hose.

�

The filler neck on the fuel cell accepts a 1.75" ID hose.

�

�

Calvin fabricated this coupler to mate the two fuel hose elbows together.

�

�

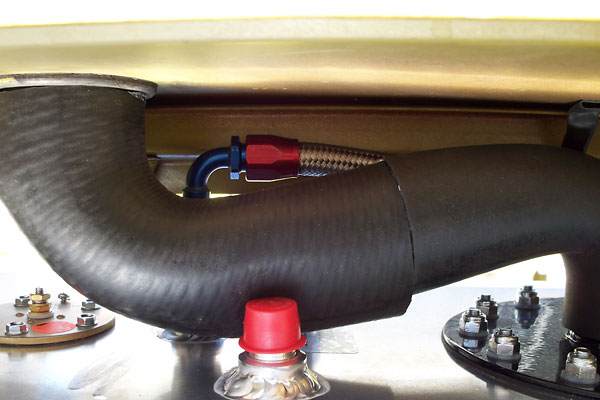

Foreground: the hose for the rollover vent, connected with a "dash eight" (half inch)

�

AN fitting. The fuel cell came with similarly large fittings for its other two ports.

�

Calvin used dash eight to dash six converter couplings into 3/8" braided hoses.

�

�

Calvin's original plan was to use racecar-style fuel cell foam to prevent sloshing of fuel within his

�

tank. That foam breaks down and has to be replaced every few years, so instead he decided to

�

add a simple sump to the bottom of his tank and draw fuel from there. 9 holes, 1.125" diameter.

�

(In the righthand center hole, you can see the original but now-obsolete fuel pickup tube.)

�

�

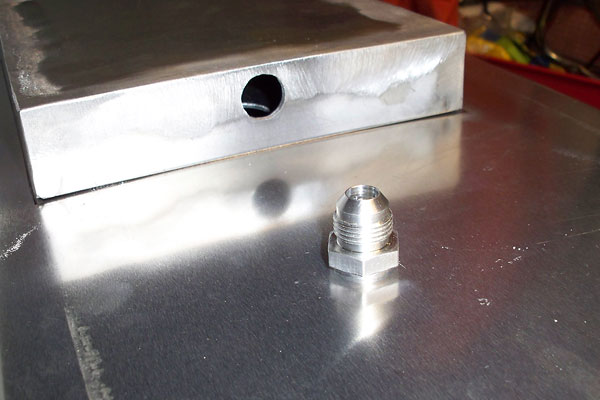

The sump measures 8" by 10" by 2" deep. At right: 8AN aluminum bung.

�

�

With the sump TIG welded into place, the bung points to the driver's side.

�

�

Aircraft style connection of the Aeromotive high pressure fuel pump to the fuel tank. From

�

the pump, gas goes directly into a filter assembly with a built-in pressure regulator.

�

A portion of the fuel continues to the engine. Excess is routed back to the tank.

�

�

In the event of an accident, this inertia switch would shut-off the high volume fuel pump.

�

Front Suspension and Brakes

��

�

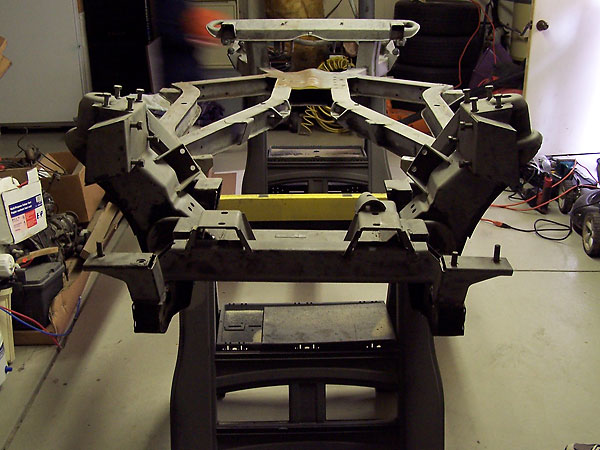

This is basically a "before photo." Many alterations to the TR6 frame will be shown below.

�

�

Original Triumph TR6 front anti-sway bars are mounted quite low, and vulnerable to contact with curbs.

�

Calvin followed Ken Hiebert's lead and re-mounted this Good Parts anti-sway bar higher, on the top surface

�

of the car's skid plate. This is, however, an early photo of that. He subsequently shifted the skid plate and

�

anti-sway bar forward about 1.25". Doing so improved the anti-sway bar link geometry and also provided

�

more clearance for radiator installation. (He lowered the radiator slightly for filler cap to hood clearance.)

�

�

Quick ratio steering rack: 2.5 turns lock-to-lock versus 3.5 turns as standard.

�

�

Calvin initially set-up the front suspension with KYB shock absorbers, but he has recently

�

replaced them with adjustable Spax shock absorbers. He has them set pretty stiff too.

�

�

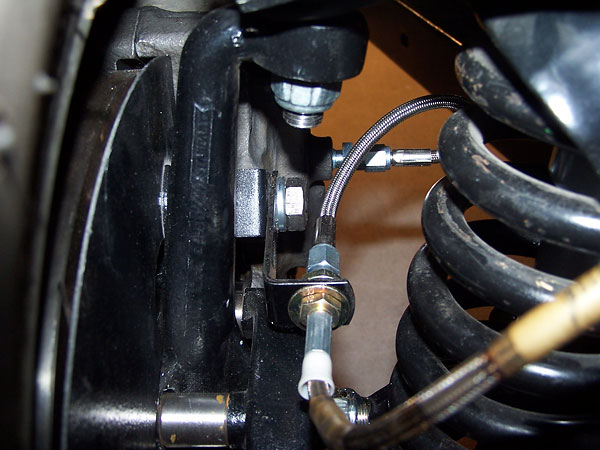

To route the steering around the engine, Calvin used Woodward Power Steering Products components.

�

He special ordered u-joints to mate to stock Triumph TR6 parts (0.563" by 36 splines at both the

�

rack and pinion and the steering column.) The opposite ends of those u-joints and the components

�

in the middle are all 0.750" by 20 splines.

�

�

There are two tubular intermediate shafts, both constructed of 0.75" OD by 0.490" ID material.

�

Woodward sells splined tips that get welded into these. To install them, Calvin drilled out the

�

tubes to 0.514" (1.25" deep) on all 4 ends. The OD of the splined tips were 0.512". Plug them

�

in and they're self aligning; fire up the TIG welder and make the assembly permanent.

�

�

There are two Heim joint supports: one on the inner fender and one on the suspension tower box.

�

�

Bolt-in crossmember, added to reinforce the motor mounts.

�

�

Stock TR6 rotors, cross-drilled and slotted. Braided stainless steel brake lines.

�

�

1985 Toyota 4x4 brake calipers. Incidentally, the original Triumph dust shields were

�

still installed here, although trimmed slightly to suit the larger calipers. Since these

�

photos were taken, Calvin has upgraded to Wilwood 4-pot calipers and 12.19" rotors.

�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

Rear Suspension and Brakes, Etc.

��

�

Another before photo: this one shows rear frame design details better.

�

�

The original Triumph TR6 rear axle ratio was 3.69:1.

�

�

Nissan R200 rear end out of a Nissan / Infiniti Q45. The 3.54:1 ratio R200 rear ends came

�

with six bolt housings, whereas other versions came with five-bolt housings. Richard Good

�

offers mounting brackets for putting either version in a Triumph.

�

�

At the right you can see bracing for the transmission mounts, fabricated from thick

�

wall round tubing (1.5" OD by 0.25" wall), and 3" square mounting plates.

�

�

This photo shows reinforcing plates added to the top surface of the frame (only).

�

They're attached with plug welds plus welds around the perimeter.

�

�

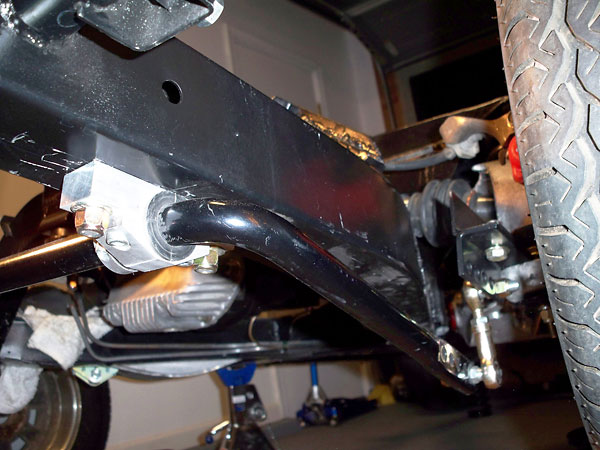

Good Parts adjustable trailing arm attachment brackets and Nylatron bushings.

�

�

Steel tubes were welded into the frame for routing fuel and brake lines.

�

�

The fuel and brake lines were strategically routed to avoid exhaust heat.

�

�

This adapter bracket for mounting an R200 rear end is from Richard Good / Good Parts.

�

�

Many reinforcement plates and braces were welded to the TR6 chassis.

�

�

Roadster Factory (Revington TR) coilover conversion kit, featuring AVO shock absorbers.

�

�

These are single-adjustable shock absorbers, although the adjuster screws are hidden.

�

Calvin drilled access holes, so he can adjust them from outside with an Allen wrench.

�

�

Good Parts rear anti-sway bar. Calvin relocated the sway bar rearward because

�

Richard Good's original design conflicted with Calvin's coilover conversion kit.

�

�

The rear sway bar has five selectable stiffness settings.

�

�

Calvin's experience is that front differential mounts are one of the weaker links of

�

the Triumph TR6 chassis, so he put particular care into reinforcing them.

�

�

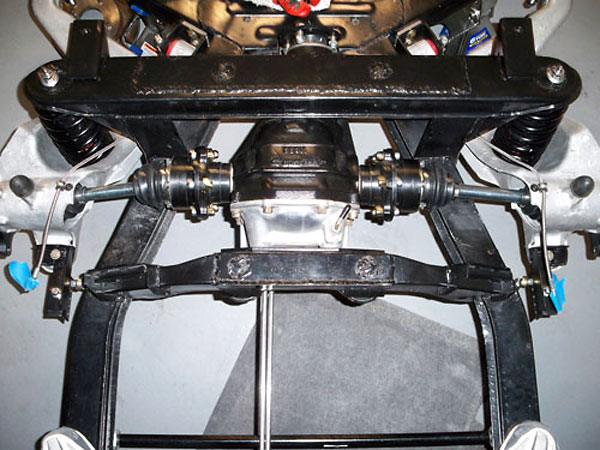

This photo is a nice overview of the rear suspension, but it also shows the 3/8" stainless

�

steel fuel line during installeation. (AN fittings thoughout. No hoses or barbed fittings.)

�

�

Triangular reinforcements have been welded-in both front-and-rear

�

on both righthand and lefthand shock absorber towers.

�

�

Close tolerance (~0.100") of CV joint boot to housing.

�

�

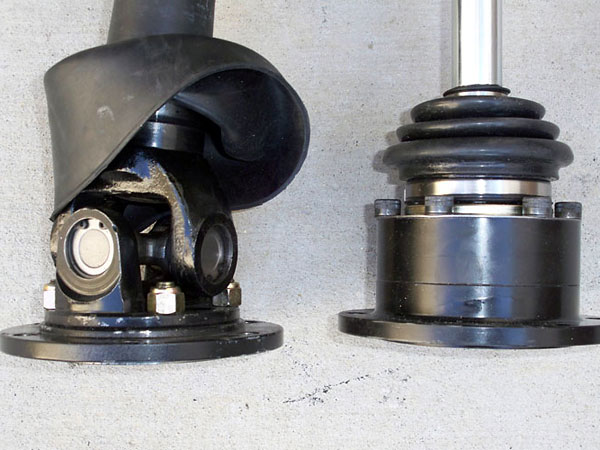

At left: an original Triumph TR6 universal joint halfshaft.

�

At right: one of Richard Good's first generation constant velocity joint halfshafts.

�

�

It only took a couple test drives to destroy one of the first CV-jointed halfshafts Calvin tried. "What!

�

They weren't designed to deliver 400+ horsepower?" Calvin called Richard Good and told him what

�

happened. Good Parts immediately sent new and improved axles at no charge. The first generation

�

version had used floating CV joints both inboard and outboard, whereas the second generation

�

design featured a floating-inboard / stationary-outboard combination.

�

�

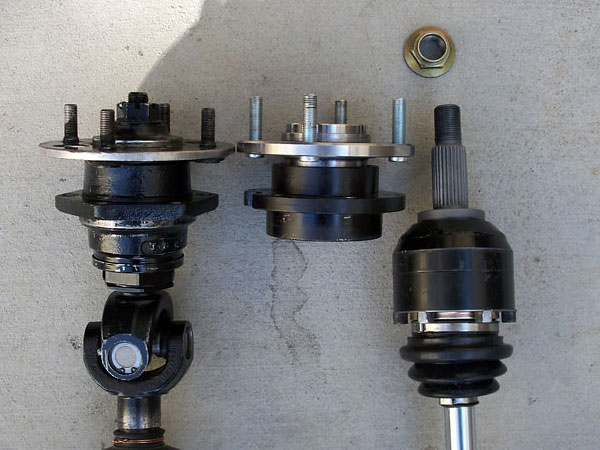

In this view, the second generation axles are marked with tags; the old ones aren't.

�

�

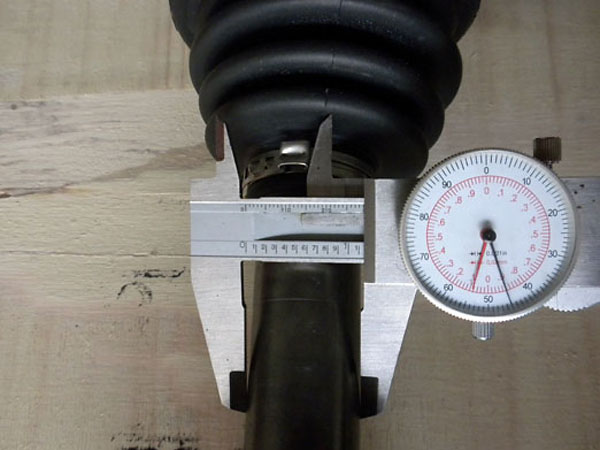

The diameter of the second generation axle shafts is 1.145", and that's about 0.20" larger

�

than the first generation shafts. The weight difference comes to about 2.6 pounds per side.

�

�

These CV joints have 5-bolt flanges, so Calvin needed to use adapters to mate to his 6-bolt

�

Nissan rear end. End result: nine bolts per axle and shorter axle shafts. Since Calvin is

�

using disc brakes instead of drums, the mounting difference figured into length

�

calculations too. (Shafts need to be about 3/8" longer per for disc brakes.)

�

�

Calvin initially set the car up with 450#/inch rear springs (shown here), but he has recently

�

updated the rear suspension with 600#/inch springs supplied by Richard Good at Good Parts.

�

The stiffer springs have cured the car's tendency to squat deeply on acceleration.

�

�

Stainless steel braid covered brake lines.

�

�

Don Watson supplied brake caliper mounting brackets.

�

�

1987 Nissan Maxima brake calipers used in combination with 1992 Nissan 240SX rotors.

�

�

There are two styles of brake caliper for a 1987 Maxima. The change occured in March of

�

that year, and the earlier design has fewer internal parts. This difference should only

�

matter if you decide to rebuild a set of these calipers yourself.

�

�

The Nissan 240SX brake rotors require a very minimal modification: the inner hole

�

that goes over the hub will need to be machined out ~0.068". Pretty much anyone

�

with a metal lathe should be able to to make this change in short order.

�

�

The bleeder screw on the caliper isn't ideally positioned. To bleed the brakes fully,

�

remove the calipers and temporarily position them so that the bleeder is pointed

�

upward. Put a spacer between the pads that's about the same thickness as a rotor.

�

�

When first installed, the emergency brake cable brackets on the Maxima calipers were

�

pointed upward. Calvin found that the cable brackets on old 240SX calipers will

�

install on the Maxima calipers and solve this problem. Now, the emergency brake

�

cables point toward the differential.

�

�

Want to know more? How To Upgrade your Triumph TR6 with Rear Disc Brakes

�

Interior Trim

��

�

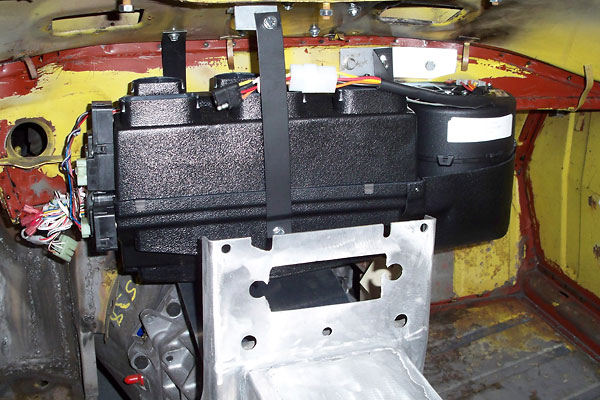

Vintage Air Mini II heater and AC evaporator unit, mounted in place. Notice that,

�

its position will require relocation of the radio downward. The new electric HVAC

�

control panel will be mounted into the original heater control area.

�

�

Specially fabricated aluminum transmission cover.

�

�

Engine computer.

�

�

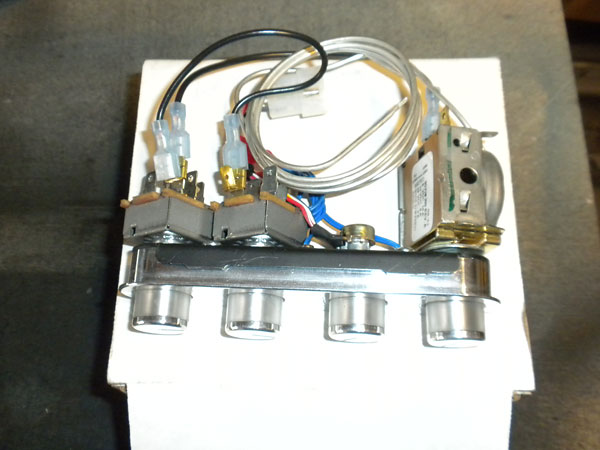

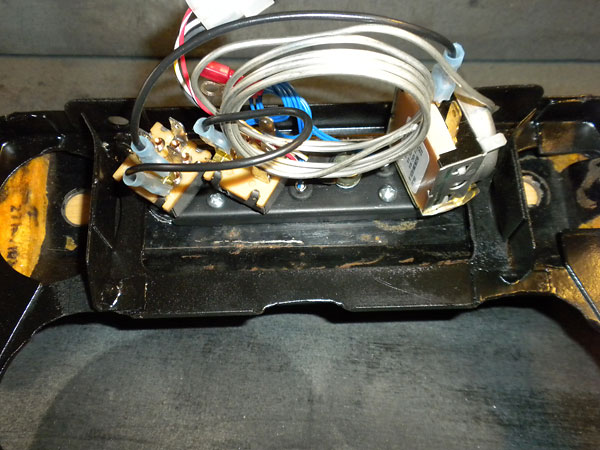

Vintage Air Mini air/heat/defrost control panel.

�

�

HVAC controls, viewed from the rear.

�

�

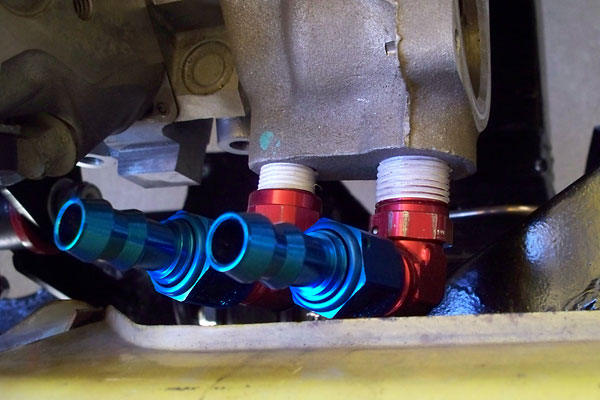

Heater hose connections on the water pump.

�

�

Heater hose bulkhead pass-through.

�

�

Air conditioning line and heater hose pass-throughs, installed.

�

�

SPAL Deluxe power window kit - electric motor.

�

�

SPAL Deluxe power window kit - cable drive system.

�

�

Mounting the SPAL power window kit in a Triumph TR6 door.

�

�

Power window switches mounted in the driver side door card.

�

�

Custom fabricated aluminum Triumph TR6 transmission cover and center console.

�

�

Installing the HVAC system and behind-the-dashboard wiring.

�

�

Upholstery wrapped center console.

�

�

Switches on the side surface of the center console are for electric seat heaters.

�

�

Cable routing.

�

�

Thin aluminum firewall between fuel tank and passenger compartment.

�

�

Rear speaker installation in the aluminum firewall.

�

�

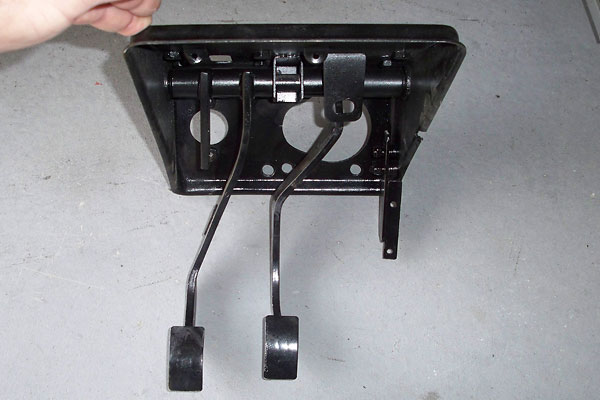

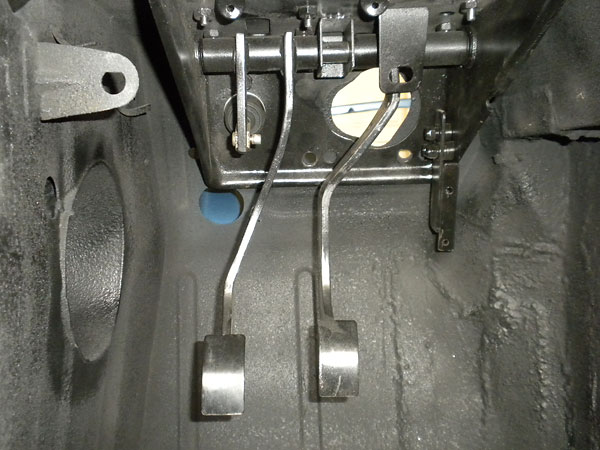

Modified Triumph TR6 pedal assembly with brake master cylinder shifted outboard 3/4" to make room

�

to package the steering shaft between the power brake booster and the LS1's driver-side valve cover.

�

�

Brake and clutch pedals have been shifted just a little bit to the left.

�

�

New cable-operated throttle pedal assembly.

�

�

Restored parking brake lever. (A heat gun was used to remove and replace the grip.)

�

�

Nissan 240SX parking brake cables, connected to the Triumph TR6 lever and bracketry.

�

Interior

��

�

Custom dashboard made from Kewazinga African rosewood by Randy Keller of Prestige Autowood.

�

�

Leather wrapped Moto-Lita steering wheel.

�

�

AutoMeter Phantom II digital gauges (set of 7).

�

�

Early Mazda Miata seats with upgraded speakers in headrests and

�

with both upper and lower cushion electric seat heaters.

�

�

Custom upholstered door panels.

�

�

Four-pin electrical contact strips at the door jams for electric window circuits.

�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

Bodywork and Paint

��

�

Modified hydraulic engine hoist and adapter frame for lifting/lowering the car's body.

�

�

A couple Sawzall cuts are sometimes needed rather early on in a project.

�

�

Having pieces in place can make it easier to come up with elegant bodywork solutions.

�

�

Calvin's home-made rotisserie.

�

�

(Instructions for building a similar rotisserie can be found by clicking here.)

�

�

This view shows from the outside how Calvin modified his trunk floor so a

�

generously sized fuel tank can be slid into and out of position inside.

�

�

The firewall section that sits closest to the transmission bellhousing has been cut out

�

and shifter rearward far enough that the engine and transmission can be installed as a

�

bolted together unit. The original battery location is therefore no longer viable.

�

�

This photo shows a trial installation of the then-new Front Runner serpentine-belt accessory

�

drive system. There wasn't as much clearance on the air conditionion compressor side as

�

anticipated, so Calvin ended up cutting out that bodywork and re-doing it. (See next photo.)

�

�

Here's Calvin's second and much improved passenger-side inner fender modification. Halfway

�

through this project, Calvin bought a Miller Diversion 165 TIG welder. He found it easy to

�

use and that it dramatically improved his welding results. Less warpage. Less clean-up.

�

�

Lizard Skin spray-on sound control and ceramic insulation were applied to both interior and

�

exterior surfaces of just about every little part of the body except for the shiniest ones.

�

The company that markets Lizard Skin (Mascoat) claims it can reduce sound transfer by

�

twelve decibels or more and also engine and solar heat transfer by 30°F or more.

�

�

The Lizard Skin sound control product must be applied first, before their ceramic heat control

�

coating. Calvin strongly recommends buying Lizard Skin's own special sprayer kit for the job.

�

�

Footbox area speaker enclosure, viewed from outside.

�

�

Footbox area speaker enclosure, viewed from inside.

�

�

Removing an old, damaged door skin: the very edge is carefully ground away with a

�

side grinder and then the folded-over lip comes free and can be set aside.

�

�

A replacement door skin, pre-primed black, is shown here ready to install.

�

�

The new door skin is folded over and crimped tight down to the inner door assembly.

�

�

This is hammer and dolly work. The curved sections take a bit of finesse.

�

�

Finally, base coat paint has been applied to the engine compartment. Toward the rear,

�

you can see the textured surface where Lizard Skin was applied before the color coat.

�

�

There's just a little bit of pearl mixed into this paint, but

�

the light is right in this view to bring out the effect.

�

�

A detail spray gun and great care are required to do a nice job like this.

�

�

Don't take shortcuts when painting door jams. Quality really shows here.

�

�

Should the rear of a Triumph TR6 be painted body color?

�

�

Calvin and Brenda looked at a lot of TR6s and decided they prefer gloss black.

�

�

Painting individual panels off-the-car isn't so hard. Getting them all installed

�

and properly aligned will be another story.

�

�

Boot lid.

�

�

Curious about what Lizard Skin weighs? The sound control product weighs 26.6 lbs per two gallon

�

pale, and covers ~100 square feet. The insulation product weighs 11.8 lbs per two gallon pale

�

and covers 40 to 70 square feet. It could easily add thirty to forty pounds to your car.

�

�

Calvin added a rubber drain tube on both sides. On a stock TR6, water

�

simply drips through a vent from the cowl area down onto the inner sill.

�

�

The inboard surfaces of the TR6 windshield surround are covered with

�

pre-formed vinyl that's held on with strong 3M spray adhesive.

�

�

Careful, now!

�

�

Comparing the two modified inner fenders, the drivers side was done with a MIG welder

�

whereas the passenger side was done with a TIG welder. The TIG welder transfers less

�

heat out into the sheetmetal and therefore causes less warpage.

�

�

The black paint at right is high-temperature rated. (It will be closer to the exhaust.)

�

�

With the newly painted body bolted down, final assembly will move along quickly.

�

�

PPG Atlantic Pearl Blue two stage paint with white pearl ghost stripes. The ghost stripes are base

�

paint but with no (blue) tint; white pearl was mixed-in instead. They're painted overtop two coats

�

of the regular (blue) base coat, and then two coats of clear coat were applied over everything.

�

Exterior

��

�

Calvin's exceptional Triumph TR6 V8 project was journaled in this message board thread.

�

�

The British call this a "Q car". Nothing on the outside hints at what's hidden inside.

�

Who would guess that this Triumph TR6 puts over 400 horsepower to the ground?

�

�

Okay, maybe dual Monza 2.5"-to-4" glass-pack tailpipe tips are a subtle clue.

�

�

Brenda showed tremendous natural talent during the BritishV8 2012 autocross.

�

�

Smooth and fast at the same time.

�

�

Rota RB Hyper Black aluminum wheels (17x7.5, 4-100mm lug spacing, +45mm offset).

�

�

Yokohama S-drive w-rated 245/45R17 tires (~10" wide).

�

� Generally, photos showing the course of this project are by Calvin Grannis.� Photos by Calvin have three-letter codes in their file names.� Photos showing the completed project are by Curtis Jacobson.� Photos by Curtis have two-digit codes in their names.� The two action photos (above) were taken during the BritishV8 2012 autocross by Jim Watson.� All the photos are copyright protected. Please contact BritishV8 to arrange permission before reproduction.�

�

�

�

�

�