�

�

�

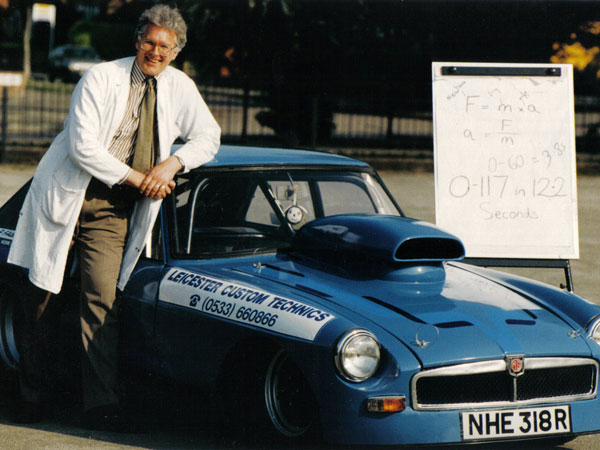

Philip Herrick's MGB GT V8 Race Car

�A Physics Teacher Demonstrates Newton's Second Law

� as published in BritishV8 Magazine, Volume XVII Issue 1, May 2009�� Owner: Philip Herrick

� � City: Melchbourne, Bedfordshire, England

� Model: 1975 MGB GT

� Current engine: Rover V8

� Conversion performed by: owner�

�

�

Having built and raced Austin-Healey Sprites from 1975 though 1988, I was �

ready to move up to an even faster class. (See the article: �

Philip Herrick's �

Austin Healey Sprite Race Cars, in BritishV8 v17/i2.) To do it right, I �

really needed to start from scratch. I had long admired the MGB-GT shape. A �

roof would certainly be a nice feature: getting soaked in open sports cars, �

watching rain come down whilst waiting to race had lost its attraction!�

�

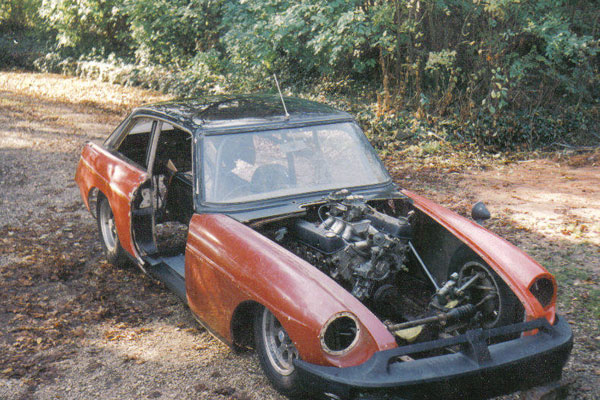

I approached a friendly local garage that specialized in MG restorations �

("Moat Garage") and a sponsorship deal was struck. I would advertise �

them in exchange for MG parts they didn't want. So I spent a day with a �

hammer and chisel taking the body off a rusted out BGT that had acted as �

a donor car for a new "Heritage" roadster they were building. The rusty GT �

also provided two fibreglass (aftermarket) front wings and another car a �

provided a fibreglass (aftermarket) rear wing. Two old rusted doors were �

gutted; later, new door skins would be fitted.�

�

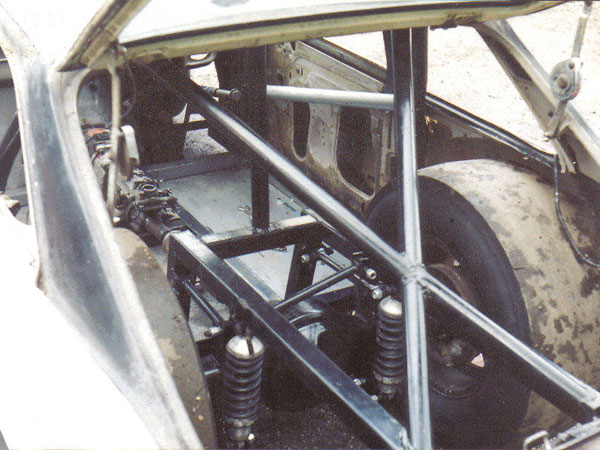

I considered various options for the front suspension and steering. �

A Sprite or Midget suspension would be much lighter than the MGB front end. �

Smaller wheels and narrower track would mean that I could radically lower �

the front end. I located a suitable donor car and cut off the front with a �

hacksaw and gas torch. Midget pressed-steel, square section, chassis rails worked �

nicely because they allowed two 2" box tubing to be forced inside and welded. �

These main, lower chassis rails ran to the back where they were �

then kicked up and welded to go over the rear axle.�

�

�

�

The bodyshell was temporarily positioned over the frame, and an 8-point roll �

cage was designed, cut, bent and welded together. The front tubes located onto the �

front cross-member and the rear diagonal tubes tie in the back of the car and �

provide lateral strength to the back axle location.�

�

The Engine and gearbox were positioned as far back in the chassis as possible, �

without cutting through the scuttle, to allow maximum weight transfer for �

traction. Suitable brackets were cut and welded onto the chassis rails; then �

mounting plates were cut and drilled to bolt the engine and gearbox in place.�

�

�

November 1988

�

�

A steel floor pan was installed.

�

� An additional central down tube was added later from the rear roll hoop � down to a cross member at the top of the kick-up section. This provided � more structural strength. (I made a physical model of the chassis out of � wire to see how it withstood forces in miniature). Two further tubes were � placed diagonally across the door openings.�

��

�

February 1989

�

�

� The bodyshell was then positioned on the chassis and the door pillars bolted � to the front lower crossmember. The rear was secured, using tubes to act as a � hinge, to allow the bodyshell to "flip up" for maintenance. A new fibreglass � rear wing, bonnet and "Sebring" style rear valance were purchased and fitted. � New steel outer sills were bent to allow the car to be lowered even further.�

��

�

February 1989: building the rear suspension.

�

�

A BMC "C series" Sherpa van axle was purchased from a wreckers yard and �

stripped down. The outer tube was sectioned and the half shafts cut and �

shouldered. The flanges were bored to suit and the shafts welded at the �

shoulder and around the flange. The half shafts were then used to guide �

the re-welding of the narrowed outer casing. Mounting plates were welded-on �

for a four bar suspension system. Second hand Bilstein telescopic coilovers �

were purchased from a local Formula 3 circuit racer and 3 ½" dia, 250 lb/in �

springs were fitted. A short Panhard rod completed the rear suspension. �

Rubber "Metalastic" bushes were used.�

�

The steering column was a Mark 1 Sprite shaft that was lengthened so that �

the seat could be as far back as possible. A 5-point racing harness was �

fitted together with a second hand fibreglass bucket seat.�

�

�

April 1989: the body was then sprayed black at Moat Garage.

�

�

May 1989: The interior was panelled in aluminium sheet. I also fabricated an aluminium fuel tank.

�

(BP Fabrications did the TIG welding for me.)

�

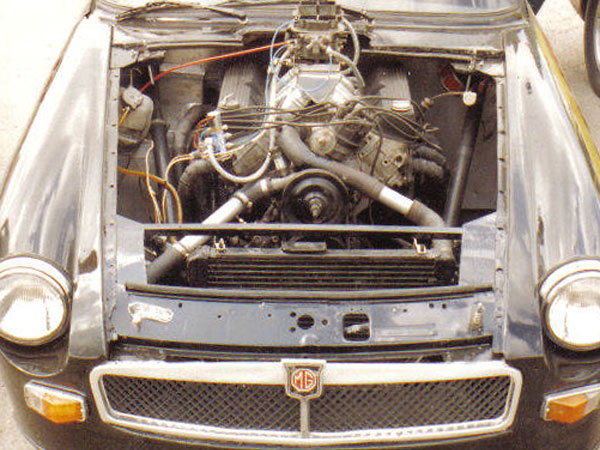

� Electrical wiring and plumbing of the water, fuel, brake and clutch systems � then took place. I used a reversed MGB combined brake and clutch master � cylinder assembly with the pedals cut and re-welded. The radiator from a � BMC Mini was installed with a manually controlled electric fan.�

��

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

� Needless to say it was a last minute rush to get the car just about finished. � The engine was finally started the night before the first race... but it caught � fire in the engine valley area! The dry powder fire extinguisher did its job � magnificently, but then it was yet another job to clean up the powder.�

� ��

�

Avon Park Raceway, 1989

�

� Initial runs were plagued with huge backfires because the camshaft was � worn out. (The second-hand "good" engine was anything but good!) A new cam � and a nitrous oxide system soon had the engine performing well.�

��

�

Weber 34 DGAS on a custom fabricated aluminium high-rise manifold.

�

�

�

�

Avon Park Raceway, 1990: "It had a pronounced 'twist' off the line."

�

�

I changed to stiffer rear springs (350 lb/in), then removed the Panhard rod and put �

a lower diagonal brace together with Rose joints (i.e. Heim joints) in lieu of �

rubber bushes. One of the rear axle mounting plates broke away from the axle and �

was re-welded.�

�

The exhaust was changed from an 8-to-4-to-2-to-1 system, to a 4-to-2-to-1 �

pair of pipes. �

�

�

For the 1991 season, the black paint scheme was replaced by the pale blue

�

"Leicester Custom Technics" colours, and the bonnet received a proper hood scoop!

�

�

�

�

�

�

At the rear: 15x8 steel wheels and 8"-wide M&H "Racemaster" drag slicks.

�

�

�

In 1992, my main sponsor "LCT" became "S.G. Carcraft"

�

�

�

�

Avon Park Raceway, July 92

�

�

In 1992 a new engine was built with a solid lifter RS 256 Crane cam, �

Crane solid lifters and adjustable pushrods. A set of forged pistons �

(+0.020") meant that I could increase the nitrous oxide injection �

quantity and hence power output. The SD1 cylinder heads were ported �

and larger diameter valves were fitted with stronger valve springs.�

�

The carburettors were initially a pair of Weber 34 DGAS on a custom �

fabricated aluminium high-rise manifold with a four jet nitrous system. �

In June 1993 I fitted a 600cfm Holley "Double Pumper" with a single �

central nitrous jet.�

�

�

�

In 1993 the car was resprayed in metallic "Rover Racing Green"

�

with pale green flames by Calvers Autotech.

�

�

York Raceway, May 93

�

Final Configuration

�| Engine: | �Rover V8 215ci (3523cc). Custom 2 x 34 DGAS Weber on fabricated �

high-rise manifold, or 600 Holley "Double Pumper" carburettor. �

Hi-Power Nitrous. Crane F256 mechanical race cam and Crane solid �

followers Crane adjustable push rods. Stock Lucas plus Lumenition �

Electronic Ignition | �

| Cooling: | �British Leyland "Mini" radiator, plus manually switched electric fan. | �

| Exhaust: | �fabricated tubular tri-y headers. | �

| Transmission: | �standard Rover 5 Speed manual with direct top gear. Standard Rover V8 �

diaphragm clutch. Shortened Rover V8 prop shaft. | �

| Rear Axle: | �British Leyland "C" series (from a Sherpa van), narrowed and with �

a locked differential. 3.9:1 ratio. | �

| Front Suspension: | �standard 1275cc Sprite/Midget coils springs and lever arm shock absorbers. | �

| Rear Suspension: | �custom 4-link rear suspension, Panhard rod, Bilstein coil-over shock absorbers. | �

| Brakes: | �stock MG Midget front discs and pads. Sherpa rear drums and shoes. | �

| Wheels/Tires: | �front - MG 13x4.5 wheels, 145 x 70 tires, � rear - 15x8 steel wheels. 8" wide M&H "Racemaster" drag slicks. | �

| Weight: | �Approx 1700lbs | �

| Electrical: | �standard Smiths Sprite/Midget gauges, except for a recalibrated �

(for 8 cylinders) rev counter. | �

| Other Mods: | �full 11-point roll cage. MG Midget front cross member.�

Fibreglass bonnet. Fibreglass front and rear wings grafted around �

MGB GT body and roof section. Stripped steel doors, Perspex/Lexan windows. �

Aluminium sheet interior. Steel plate clutch shield. | �

| Performance: | �standing start quarter mile in 12.2 seconds (119mph). | �

| Date Completed: | �

build started Nov 1988. First raced in May 1989. � (I drag raced it for about five years before selling the car.) | �

| Comments: | �

the car was very reliable and with development to the engine, did run �

faster each year. One welded bracket broke on the rear axle. The �

differential shattered after about 4 years racing. However to run much �

faster I was going to need to spend much more money. Having raced for �

20 years, I decided to sell the car - and I started to restore railway �

wagons on a preserved steam railway! | �

�

�

York Raceway, June 1993: By mid 1993 I was frustrated by the car not going significantly faster despite

�

the new engine, big valve heads, new carburettor, new fuel pump and updated nitrous system.

�

�

�

I put mg MGB GT racecar up for sale and went to one final race in August.

�

The car sold quickly, and it was taken away on August 31st.

�

� Editor's note: although Philip has given up drag racing, he's still enthusiastic� about building cars. At present he is putting an Alfa Romeo 3.0L 24-valve � V6 engine into the rear of an Alfa Romeo Sprint. The results will resemble the � Group B "6C" rally car built by Autodelta for Alfa in the mid 80's. However, � Philip's version will use an Alfa "164" (transverse mounted) 3.0L donor engine, � rather than the 2.5L engine from a Alfa "GTV" (longitudinally mounted) engine.�

�