Ken Costello and the MGB-V8

�| �

as published in MG V-8 Newsletter, � Volume IV Issue 2, August 1996� � by Robin Weatherall� � [With initial publication of this article, � MG V-8 Newsletter's editor, Kurt Schley � noted: "Robin Weatherall is the Membership � Coordinator for NAMGBR (The North American � MGB Register), past proprietor of "The MG � Centre", and has been heavily involved in � all facets of the MG hobby for many years. � Robin owns more than 30 MG's, including an � MG V8 roadster conversion, a GT V8 conversion, � a national concours winning MGA coupe, and � one or more examples of darn near everything � else, placing him in major contention for: � "He With The Most Toys".] � | �

�

� KEN COSTELLO Photo courtesy of Ken Smith - "MGB Driver" magazine � | �

�

Over the last 23 years there have been numerous versions of the history behind �

the MGB V8, but none have ever fairly presented Ken Costello's side of the story. �

Rumors and opinions have been presented as fact, and innuendo has declared �

Ken Costello's conversions amateurish. Now is the time to put the record straight �

and give Ken Costello his rightful position in MG history.�

�

First a brief background on the aluminum engine which made the MGB V8 possible: �

this 215.5 cu. in. 3531 cc, 318 lb. engine was originally designed by Buick and �

supplied in nearly a million vehicles during 1961-63. Unfortunately, considerable �

trouble was experienced due to chemical reaction between the coolant, which was �

not silicone based in those days, and the aluminum block. When used incorrectly, �

the coolant led to fouling of the waterways and overheating. Buick dropped the �

engine from production in 1963. J. Bruce McWilliams, head of Rover USA, was �

friendly with Karl Kiekhaefer of Mercury Marine and during a visit to his �

workshop spotted a Buick 215. Rover was looking for an American V8 to power �

the stodgy Land Rover for the US market, negotiations resulted in a manufacturing �

license and the success story started. British manufacturers were unfamiliar �

with aluminum die casting at that time, so the big difference in the Rover �

manufactured blocks and heads was their being sand cast.�

�

This engine has powered many Rover models over the last 30 years, from the �

Rover 3.5L to the Range Rover. Design development has taken it from 3.5L �

through 3.9L to the present 4.2L and 4.6L, and from twin SU HIF-6 carbs to �

multi-port fuel injection. As it is planned to continue using the unit well �

into the 21st century, this engine could easily become a 50 year success story!�

�

Within a couple of months of launching the MGC, it was obvious the car would �

not be a success. Reviews in the motoring press condemned its handling as a �

performance vehicle (as an MGC owner I am one of the multitude who thinks �

this is a grossly unfair assessment) and if MG was to maintain its market �

position against the challenge posed by the Triumph Stag and Sunbeam Tiger �

another model was a necessity. In 1970 Charles Griffin, Chief Design Engineer �

for British Leyland, was instructed to investigate dropping the Rover aluminum �

V8 unit into the MGB. His production planning team looked at the project for �

several months and in November Griffin sent a memo to BL chairman Lord Stokes �

stating "We have investigated the possibility of installing the Rover (Buick) �

V8 in the MGB and have determined the car would have to be widened at least �

3-1/2 inches, obviously this is not feasible."�

�

Meanwhile Ken Costello had already solved this "not feasible" problem without �

widening the car! How did this come about? It is necessary to know something �

of this tenacious little Englishman. Ken was born in Kent, the outer SE �

suburbs of London. At age 18 he graduated from Woolwich Polytechnic, where �

he had studied auto engineering, and started work at the Motor Industry �

Research Department on the Great West Road in Brentford, Middlesex. In 1959 �

a friend with a Mini which was his 'daily driver' told Ken, "If you tune �

this you can race it", and so the road to the MGB V8 was started. Ken tuned �

the Mini, drove to Castle Comb race track, and entered his first race in �

the Special Saloons Group 3 classification. He won and set a lap record! �

Now he got serious, thoroughly rebuilt an 850 cc mini and lightened it with �

fiberglass doors etc.; he was very successful., setting lap records at �

Brands Hatch, Mallory Park, Castle Coombe, Crystal Palace and Snetterton �

(where he was timed at 129 mph). The car was so fast he was put in the �

upper 1200 cc class and still consistently won.�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

One day in 1962, while driving on the M1 motorway. Ken had a dust up with a �

Mark II Jaguar, impressing its driver. When they stopped for petrol Ken �

discovered his opponent was a Jaguar salesman at Cripps Brothers, a Leyland �

dealer in Sidcup, Kent. The salesman introduced Ken to the Lady Peggy Cripps, �

owner of the dealership, and within a couple of weeks he was running her �

'Special Tuning Division' along with racing for her.�

�

The car was a 1275 Mini bored to 1293 cc. On one occasion at Brands Hatch it �

was reluctantly allowed into a 1330-2000 cc race which Ken easily won. In �

spite of the win he was told it must be over 1300 cc to be in the Championship �

race! Ken bored the block to 1304 cc and entered. Just before the race he was �

made to remove the head in the scrutineering bay so the bore could be measured. �

Later, as he sat on the grid in pouring rain, Clerk of the Course Nick Syret, �

told Ken "this is probably the only car checked in case it was undersized!" �

Ken won the championship. Over ten years he took part in over 400 Saloon races �

with several cars including a Broadspeed Ford Anglia owned by Laural Ward.�

�

His next step was Formula 3 when Cripps bought the ex-checkered flag Brabham �

BT 20 with a Cosworth MAE 1000cc engine. 1966/67 saw Ken earning a lot of money �

driving this Brabham for the movie Grand Prix. He has many stories about this �

experience but one in particular is memorable: Yves Montand was being filmed in �

the cockpit of a race car as it was towed, at speed with its front wheels removed, �

behind a Ford GT-40 containing the camera. Obviously Yves Montand had no control �

over the car and as he was towed at very high speed round a bank his face drained �

of color and his bladder opened! This shot is in the movie as his car supposedly �

crashes! While filming at Monza Ken visited the museum there, he was intrigued �

by a small block Maseratti V8 engine and the seeds were sown for a 'really fast' �

small car.�

�

Back in England, after filming was completed, he happened to spot a Rover V8 on �

the floor of the workshop at Pipers Garage in Hayes, Kent. After mulling it over �

for a while he borrowed a red MGB roadster from an Insurance Assessor friend, �

bought a used Oldsmobile 215 engine and set to work. By the end of November 1969, �

after six months of trial and error, the car was running and the enormous potential �

became obvious. The next car converted was a GT, owned by Lady Cripps, with several �

improvements including the rear axle from an MGC. The performance was incredible. �

Ken took the plunge and went into business for himself, opening premises in �

Farnborough, Kent with 8 employees. The V8 Conversion Company was born. Customers �

would supply the car which Ken and his mechanics would convert using a Rover P6 �

engine and standard MGB gearbox. The cars were easily identified by their unique �

egg-box radiator grille, Jensen alloy wheels, Costello V8 tail-badge and hood �

with a round bubble to accommodate the carbs.�

�

The February/March 1971 issue of "Motoring News" featured a road test of Ken Costello's �

MGB V8, hailing the car as a breakthrough in performance for sportscars. A comparison �

of performance figures illustrates the huge improvement over the 1800cc MGB.�

| MGB | Costello V8 | |||

| 0-60 mph | 12.1 sec | 7.8 sec | ||

| 0-100 mph | 19.2 sec | |||

| top speed | 104mph | 130 mph | ||

| horsepower | 155 bhp at 5000 rpm | |||

� On 18th May 1971, shortly after the article appeared, Ken received a letter:�

��

�

British Leyland (Austin-Morris) Limited

�

Longbridge,

�

Birmingham.

�

�

Dear Mr. Costello,�

�

Having recently read the article in Motoring News on your construction of an MGB with the V-8 Rover engine,

�

I have attempted to contact you by telephone but without success.My reason for contacting you was to

�

express my interest in this installation and also say how pleased we should be here at Longbridge if you

�

could possibly see your way clear to arranging for us to have such a vehicle on loan for a day or two.�

�

I trust you will be able to comply with this request, if so perhaps you would be good enough to telephone,

�

or write me at the above address, in order that suitable arrangements can be made.�

�

Yours sincerely,

�

C .A.Griffin

�

Director of Engineering�

�

�

�

Ken telephoned Griffin and told him he didn't have a car available, but would call at �

Longbridge as soon as he did. Several weeks later Ken turned up at the factory without �

an appointment and asked for Charles Griffin.�

�

"Do you have an appointment?" he was asked.�

�

"No", Ken replied.�

�

"He's too busy to see you without an appointment."�

�

"Tell him Ken Costello is here with his V8 MGB."�

�

A couple of minutes passed while the guard phoned Griffin. "He will be down in a minute."�

�

Charles Griffin arrived almost immediately, accompanied by several members of his �

staff, including Harry Webster and George Turnbull. The car was whisked away and driven �

around the test track while Griffin and Ken chatted over lunch. After an hour the car �

was back and an impressed Griffin told Ken "This is a first class job, how can we help you?" �

Ken's concern was crown wheels and pinions, so he asked "How many 3.07:1 crown wheels and �

pinions are available now that MGC production has ended?" �

�

"I will check and see what stock we have." Griffin replied.�

�

A week later Ken was asked to take the car to BL head office in London's Berkeley Square �

so the Chairmen Lord Stokes could see it personally. After he had taken a short drive he �

asked Ken "What will you do if we produce this?" �

�

"I'll keep on building them because it will take you two years to get into production", �

was Ken's reply.�

�

In late 1971 a brand new LHD harvest gold MGB-GT and Rover engine arrived from Abingdon �

with a request to fit the engine into the car. Two weeks later Ken personally delivered �

the converted car to Special Tuning in Abingdon. (BL never paid the £1000 invoice for the �

work). The MG engineers examined the car closely and, excited by the prospect of building �

their own version, forged ahead with a prototype, and in August 1973 launched the �

MGB GT-V8. A couple of weeks before the launch Ken took out the only advertisement �

ever for his conversions, it sarcastically warned customers to "be aware of imitations"!�

�

Lord Stokes immediately sent a directive to all dealers instructing them not to sell any �

new V8 engines without an old unit in exchange, a thinly disguised effort to cut off �

Ken's supply of engines. Ken, knowing Belgium had imported a lot of Skylarks and Cutlasses, �

sent a truck over and after several weeks scouring junk yards returned with 40 Buick and �

Olds blocks which were rebuilt with Rover parts. But with the availability of factory cars, �

and the cheaper price tag, Ken's customers shrank to a trickle. In all Ken reports �

converting approximately 225 MGB's during the 70's of which approximately 25% were roadsters, �

one was an automatic LHD for a Canadian customer (this car was at MG 92 in Peterborough. �

Ontario) and one was an MGC.�

�

�

The Canadian Costello V8

(Notice the left-hand-drive steering wheel placement.)

�

�

It should be remembered that during the development work MG made a number of changes to �

the MGB to enable the shell to take both the V8 and standard 1800 engines. These changes �

have made present day conversions a much easier project than that faced by Ken Costello. �

Engine mounts were modified, radiator moved forward, twin electric cooling fans added and �

radiator duct panel redesigned, oil cooler mounted under the radiator duct, inner wheel �

arches were recessed to accommodate specially cast exhaust manifolds, rear bulkhead �

reshaped to take V8 bell, steering shaft lengthened to move the knuckle joint away from �

exhaust manifolds, steering column shortened, A-arm bushings up-rated, brake servo added, �

rear wheel brake cylinders and front calipers enlarged, hood profile reshaped to �

accommodate the SU carbs, with specially designed air cleaners, mounted on a new plenum. �

Several changes were also incorporated in the engine including a reshaped sump, oil �

cooler remote plate, new alternator cradle, shorter pulleys and water pump, and MG rocker �

covers. �

�

Obviously MG expected to sell a lot of cars but "unfortunately the launch corresponded �

with the gasoline crisis and the trend towards more economical vehicles." That has always �

been the official line but recently new information has shown that in �

fact the car's short production run was the result of BL's upper management being run �

by Triumph men. MG produced seven LHD USA spec MGB V8 GT's which were shipped to this �

country for certification by the Department of Transportation (one of these is owned by �

Lyle York in Indiana). MG planned to revitalize sales in this country by producing the �

V8 in large numbers for export. The official story has always been that they were never �

certified due to MG not agreeing to crash test the required number of vehicles. This �

turns out to be untrue, the MGB-GT-V8 was Type Certified by the US Department of �

Transportation. What stopped its export from the UK was BL's decision not to create �

competition for Triumph models, including the TR-7 which was about to be launched! �

Imagine what the response would have been to the MGB V8 in this country! MG would probably �

never have closed down and there would probably have been as many as 100,000 V8's produced. �

Production ceased after only 2591 cars.�

� Ken Costello, never being one to rest on his laurels, had already decided on a new � direction. During the late 70's he sold The V8 Conversion Company, set up a comprehensive � workshop on his property in Sidcup and turned to a new challenge. The standard MGB � gearbox wasn't strong enough for the V8 torque. It was always a weak point on both � conversions and factory cars. Ken had looked for an alternative and quickly discovered � there wasn't one easily available in the UK. He turned his attention to the design of � a strong five speed unit. Simplicity was the key word here along with low production � cost. Ken's design qualified in all those areas clam shell case that could be opened � with just two allen keys, separate bell housing and gears cut the opposite way to the � norm. The Costello 5 speed is small, strong and easy to service, can be fitted to � either the 4 cylinder or V8, removed from the car, opened and inspected, and then � replaced in an hour. In spite of all the advantages the box has been a victim of � British industrial stagnation, bank shortsightedness and mismanagement, therefore � never entering full-scale production. In the late 1980's Ken beat Rover to the punch � by converting MGB's to fuel injected V8 power, with several cars running in Britain � and one in the USA, more than two years before the RV8.�

��

�

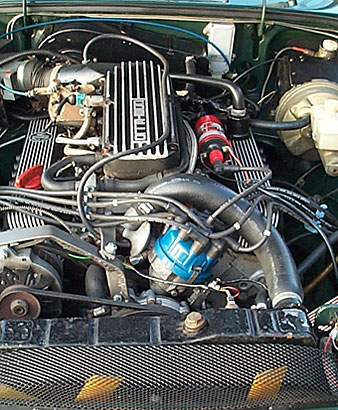

The Costello MGB V8 Fuel Injection System

�

� He took the standard Range Rover Lucas multi-port injection system and modified it to � fit neatly under the bonnet of an MGB. To accomplish this he designed and manufactured � a plenum which not only allows the standard bonnet to be used without modification but � can be adapted to either RHD or LHD cars. Along the way, Ken also designed an ABS � brake system for the MGB and a heater fan that really will keep the windshield clear! � A new front suspension design is in prototype stage and who knows what Ken's fertile and � innovative imagination will come up with as he shows no signs of slowing down after more � than 40 years in the auto industry.�

��

�

�

�

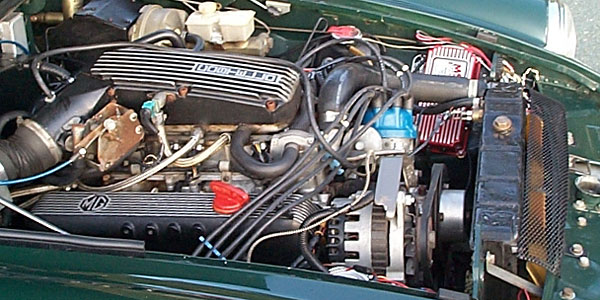

A second example installation of Ken Costello's fuel injection system on a North American MGB.

�

�

� When Ken Costello converted that first MGB he began a historical journey that resulted � in the re-introduction of the MG Marque with the MGF. Without Ken Costello there would � certainly be no MGB GT V8, therefore no MG RV8 and no MGF. The MG world owes him a debt � of gratitude and recognition as a major figure in the history of the marque of friendship. �

�� When we originally published this article, we illustrated it with the black-and-white � photo above. Additional color photos for internet republication have been graciously � supplied by frequent British V8 contributor Jake Voelckers.�

�

�

� BritishV8 Magazine has assembled the largest, most authoritative collection of � Costello V8 information you'll find anywhere. � Access our � Costello V8 (and "factory" MGB GT V8) article index by clicking here. �

�