�

�

Steve Kimball's 1977 "M Gee Bee" with Buick 215 V8

� as published in BritishV8 Magazine, Volume XXI Issue 1, July 2013�� � Owner: Steve Kimball

� BritishV8 UserID: eyeosteverino

� City: Columbus NM

� Model: 1977 MG MGB

� Engine: Buick 215 V8

� Built by: owner.

�

Steve Explains his M Gee Bee Project:

��

My interest in aircraft from the Golden Age of Air Racing and my scale model of the�

1931 Gee Bee Model Z aircraft were the inspirations for this build. Distinctive�

exterior features of the car include a custom fabricated aluminum front bumper that�

mimics an airplane propeller, spinners made from Freon canisters, a special low-profile�

aerodynamic windscreen, twin cockpit openings, Dacron (Ceconite) fabric and Butyrate�

dope covering on the aft portions of fuselage, wheel pants, and of course... tail fins!�

�

Major problems encountered were interference between the steering rack and oil pump�

base and the harmonic balancer. A Perma-Cool adapter and large ball peen hammer solved�

the first problem and the second was solved by cutting the aluminum ring off the�

harmonic balancer.�

�

I made my own engine mounts utilizing Tin Man Fabrications parts and the engine side�

of stock Buick mounts. This placed the engine well back and low but at the time I was�

using a bare block without the front cover or pulley and therefore wasn't aware of the�

harmonic balancer's proximity to the steering rack until installing the complete engine. �

�

I mounted a coolant expansion tank on the firewall and utilized the heater outlet from�

the stock intake manifold. �

�

�

�

1931 Granville Gee Bee Model Z

�

�

The design of the exhaust put the outlets where a radial engine aircraft's would�

be and hid the mufflers in otherwise wasted space. Louvers in the fenders provide�

an exit for the heated air.�

�

The brake master cylinder was reversed by using an old style bracket; otherwise�

it would have been too close to the exhaust system. On the clutch side, I used a�

GT6 slave cylinder and by replacing the left side bellhousing locator pin with a�

hollow one, the push rod could pass through to the modified stock clutch fork.�

I kept the stock mechanical fuel pump, and also the stock cooling fan which I�

painted yellow like an MGB fan. The Buick valve covers were painted with leftover�

MG engine paint. �

�

To sum up, this was another fun, and at times frustrating project, combining my�

fascination with the Golden Age of Air Racers, and MGs: my "M Gee Bee". �

�

Features and Specifications

�| Engine: | �Buick 215 V8.�

Kenne Bell 114A grind camshaft. �

Stock Buick four barrel intake manifold.�

Stock Rochester 4GC carburetor.�

Stock mechanical fuel pump.�

Offenhauser carb cover and custom (cowl induction) air cleaner.�

Stock Delco-Remy distributor, with breaker points.�

Melling high volume oil pump with stock bypass spring. | �

| Cooling: | �stock MGB radiator with modified inlet and outlet ports.�

Stock Buick engine driven cooling fan.�

Auxiliary (heater core) radiator mounted under left headlight bucket. | �

| Exhaust: | �homemade custom four-into-one headers.�

Dual Jeg's mufflers. | �

| Transmission: | �Borg Warner T-50 five speed transmission.�

Stock Buick bellhousing, flywheel, and pressure plate.�

Modified General Motors clutch fork.�

Triumph GT6 slave cylinder. | �

| Rear End: | �stock MGB Salisbury axle, updated with MGC 3.07:1 gears. | �

| Front Susp.: | �stock, but lowered one inch by cutting one coil from springs. | �

| Rear Susp.: | �stock, except lowered.�

Front leafspring mounts connected directly to body channels with 2x2 square tubing. �

Homemade Panhard rod added. | �

| Brakes: | �master cylinder and mounting bracket from an MGB Mk2�

(i.e. a chrome-bumper MGB with tandem master cylinder.) �

Stock MGB front disc and rear drum brakes. | �

| Wheels/Tires: | �stock MGB Rostyle wheels (under hubcaps) with Sumitomo "HTR T4" 175/70R14 tires. | �

| Electrical: | �Delco Remy alternator.�

MGB wiring harness, reconfigured to suit. �

Battery disconnect switch added.�

Top half of MGA tail lights. | �

| Instruments: | �Fiat 850 panel, with modifications. | �

| Completed: | �January 2013. Driven approximately 200 miles as of March 2013. | �

| Performance: | �no hard numbers yet, but it makes my MGB V6 seem a bit slower. | �

Engine Installation

��

�

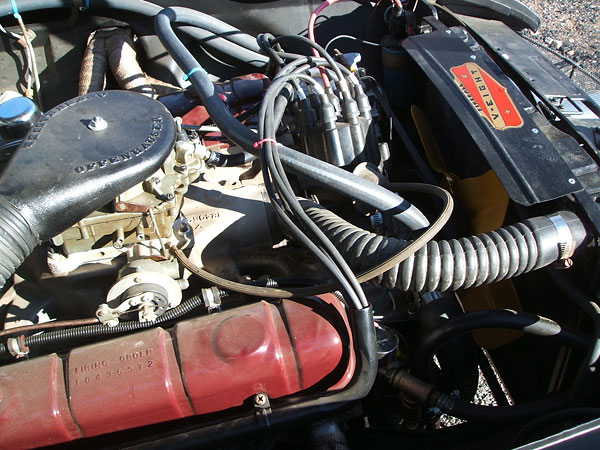

Buick's lightweight aluminum V8 has powered many homebuilt airplanes before. This one features

�

a stock Buick four barrel intake manifold,�

Rochester 4GC carburetor,�

and cowl induction.

�

�

Spark plug wires are routed through tubes made from an old TV tray.

�

Stock Delco-Remy distributor with breaker points.

�

�

The MGB coolant header tank has been relocated to high on the engine compartment bulkhead.

�

�

This rare Offenhauser cast aluminum carb cover was purchased from JC Whitney many years ago.

�

It suits the Rochester 4GC carb, but is too small for Holley, Carter, or Edelbrock alternatives.

�

Note classic Buick "Fireball V-Eight" decal at right.

�

Engine Installation Process Photos

� �

�

Custom air cleaner housing made from an old soup pot is part of a cowl induction system.

�

�

While doing a trial installation, Steve discovered a clearance problem between oil filter and

�

steering rack. This photo shows the Buick 3.2L V6 oil pump base he initially planned to use.

�

If the engine had been one or two inches higher it might have worked. Instead, he ended up

�

using a Buick 300 oil pump base with a Permacool adapter and a remotely mounted oil filter.

�

�

This photo shows how close to the frame the Permacool adapter ended up. Just enough room!

�

The adapter spins on, and Steve was careful to make sure it pointed the right direction.

�

�

Tight clearance between crankshaft pulley and steering rack.

�

�

Custom motor mounts made from Tin Man Fabrication tubes and bushings combined with the engine

�

side of stock Buick mounts. A 1/2" bolt connects to a tube welded to the stock MGB motor mount pad.

�

�

Steve feels this type of mount locates the engine better (fore and aft) and prevents torque problems.

�

Custom Exhaust System

��

�

Fabricating custom four-into-one headers.

�

�

Tack welds will hold the headers together for now. Final welding will be done off the car.

�

�

Header flanges from D&D. Pre-bent 1.5" diameter tubes from Don's Speed Shop in Tucson AZ.

�

�

JEGS High Performance muffler tucked into otherwise unused space.

�

�

Exhaust exits from holes in the side of the fuselage, airplane style.

�

Chassis Strengthening

��

�

Front leafspring mounts are connected directly to body channels with 2"x2" square tubing.

�

�

These reinforcements may also come in handy as alternate jacking points.

�

Interior

��

�

A Fiat 850 Sport Coupe gave up its instrument panel, small gauges and switches. Steve added

�

a voltmeter, 12V power socket, and a starter button. Yellow knob at right is the choke.

�

�

Fuse panel from a Yugo parts car.

�

�

MGA seat with vintage aviation seat belt.

�

�

Door pocket holds a fire extinguisher, wrapped in foam rubber.

�

�

As Steve puts it: "interior by Rust-Oleum and dust by New Mexico."

�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

Bodywork - In Process

� �

�

Steel conduit carefully bent to frame the cockpit openings.

�

�

Skinning up to the edge of the cockpit openings.

�

�

Removable passenger-side aluminum tonneau cover.

�

�

Shaved door handles, door locks, fuel filler, exterior lights, and side-view mirrors.

�

�

Framing the downsized rear wheel openings.

�

�

Skinning the downsized rear wheel openings.

�

�

Starting to lay-in new tail fins.

�

�

Welding in stringers made of thin steel rod.

�

�

Tailfins on an MGB!

�

�

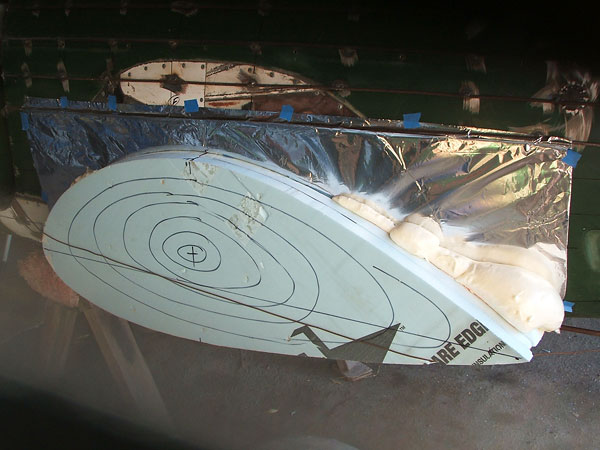

The first step of fabricating aerodynamic "wheel pants" for the landing gear.

�

�

Styrofoam extruded polystyrene foam insulation board, in four 1" thick layers.

�

�

Expanded urethane foam was used to fill odd-shaped voids.

�

�

Urethane foam can be carved and shaped.

�

�

Carving and shaping well underway.

�

�

Steve used drywall mud over drywall mesh tape for the final shaping, then covered both with

�

two coats of latex paint to protect the styrofoam from a covering of polyester resin.

�

�

A shell of polyester (fiberglass) resin will make the wheel pants reasonably durable.

�

�

Steve covered the fuselage with Ceconite brand heat-taughtened fabric and Butyrate dope.

�

Historically, dopes were formulated to shrink and taughten fabric as they dry to achieve

�

a drum-tight covering. Traditional nitrate dope only comes in clear and isn't fuel proof,

�

whereas Butyrate dope comes in various colors and is fuel proof.

�

Exterior

��

�

Steve Kimball's three amigos.

�

�

The custom fabricated aluminum front bumper mimics an airplane propeller.

�

Freon canisters have been re-purposed as propeller spinners.

�

�

GB - "Z" - 1931

�

�

Cleared for flight!

�