�

�

�

�

�

�

�

� �

� by: Jean Monfort�

� All engines must be equipped with the right distributor, giving the right � advance curve. Especially on fast road engines or rally units, it is better � to send 25,000 volts to the spark plugs at the right time than 50,000 volts � too late or too early. So, in search of the best way to set fire to the gas, � I collected some information.�

�

�

�

�

Re-Curving Rover Distributors

� as published in British V8 Newsletter, Volume XIV Issue 3, December 2006�� by: Jean Monfort�

� All engines must be equipped with the right distributor, giving the right � advance curve. Especially on fast road engines or rally units, it is better � to send 25,000 volts to the spark plugs at the right time than 50,000 volts � too late or too early. So, in search of the best way to set fire to the gas, � I collected some information.�

�

�

First Issue: How Much Range of Advance? �

� In a previous article entitled � � "3. 2. 1. Ignition! Selecting a Rover Distributor" I explained how to � enlarge the upper limit of mechanical advance on a Buick or Rover distributor. � Without modification, these distributors only give a range of about fifteen � degrees of advance. Such work is not necessary with Mallory distributors. � Most Mallory distributors are factory set to limit the advance to 24 degrees, � but can easily be adjusted from 0 to 28 degrees. A "fast-road" Rover/Buick � (with 10 to 10.5:1 compression ratio) works well from 8 to 10 degrees (idle) � advancing to 32 to 34 degrees at 3000 to 3500 RPM (and over.) �

� Second Issue: What about the advance "curve"?�

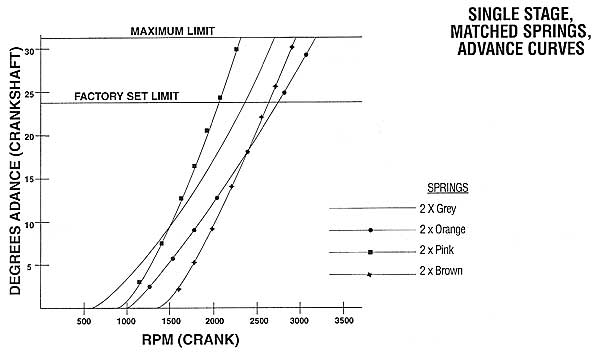

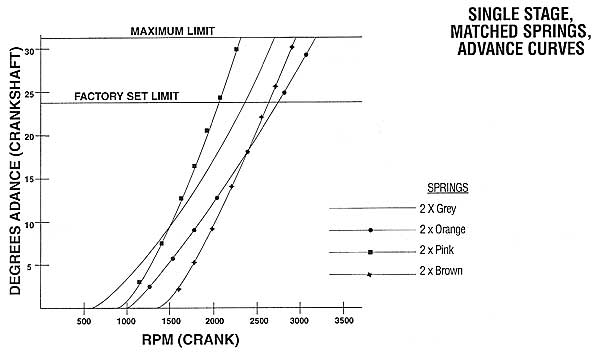

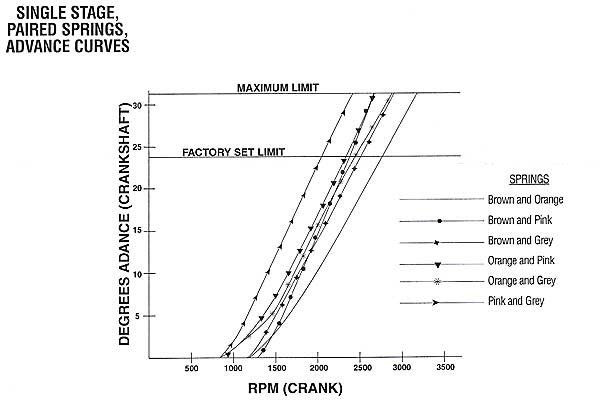

� Single-stage advance curves are common on 4 and 6 cylinder engines. Such � curves are nearly straight and allow full or nearly-full advance from 2000 � RPM, which is appropriate for race engines. With such straight curves, the � ignitions on racing engines are relatively easy to tune. (Just use trial � and error to find what advance gives the most power at high RPM.) Some � single-stage distributor curves are so radical that they're only suited for � racing V8's (e.g. Mallory 29.014 with YT or YH advance curve change kit) � as shown in Figure 1:�

��

�

��

�

�

�

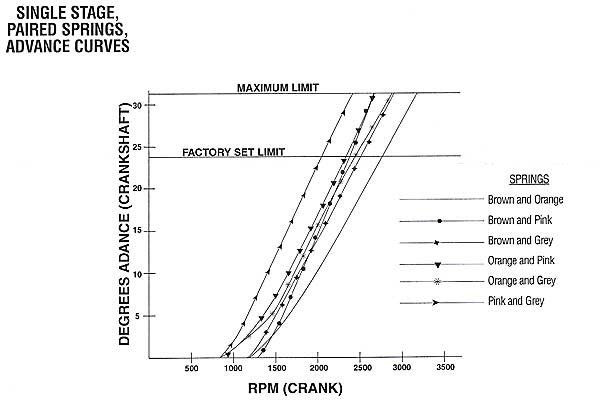

� The following graphs demonstrate the importance of selecting springs - � especially "paired" sets of springs. In paired-spring distributors, one � spring is typically longer and consequently it remains loose until over � approximately 1500 RPM. (Just to put ideas into the guys who are not � running a Mallory...!)�

��

�

�

�

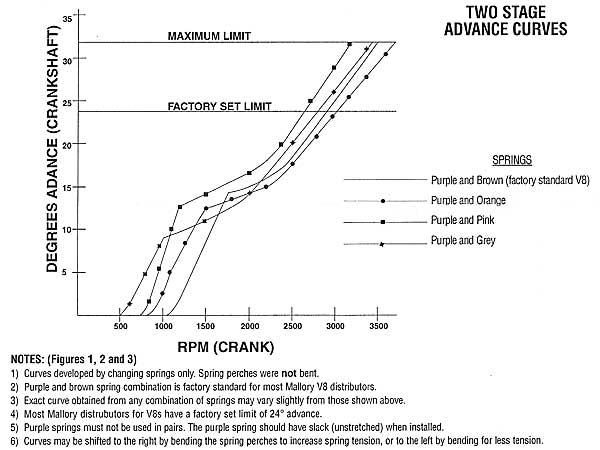

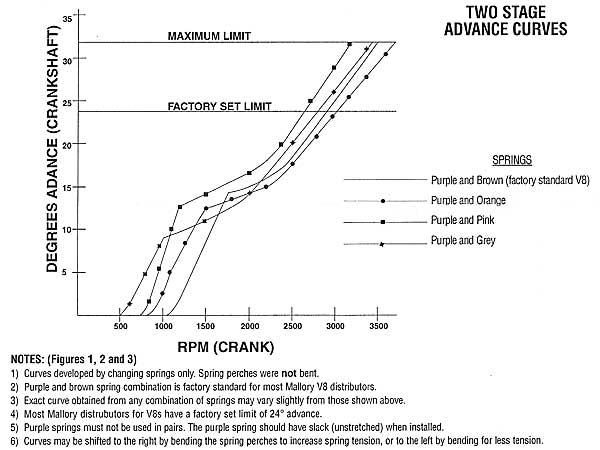

� By changing the spring combination on a two-stage advance curve distributor, � one can achieve quicker advance to 1500 RPM, slower advance change at mid RPM, � and full advance from about 3000 RPM. Studying this illustration suggest that � a great distributor can be made without any sophisticated, digitalized or � twist button systems.�

��

�

�

�

�

�

�

� In a previous article entitled � � "3. 2. 1. Ignition! Selecting a Rover Distributor" I explained how to � enlarge the upper limit of mechanical advance on a Buick or Rover distributor. � Without modification, these distributors only give a range of about fifteen � degrees of advance. Such work is not necessary with Mallory distributors. � Most Mallory distributors are factory set to limit the advance to 24 degrees, � but can easily be adjusted from 0 to 28 degrees. A "fast-road" Rover/Buick � (with 10 to 10.5:1 compression ratio) works well from 8 to 10 degrees (idle) � advancing to 32 to 34 degrees at 3000 to 3500 RPM (and over.) �

� Second Issue: What about the advance "curve"?�

� Single-stage advance curves are common on 4 and 6 cylinder engines. Such � curves are nearly straight and allow full or nearly-full advance from 2000 � RPM, which is appropriate for race engines. With such straight curves, the � ignitions on racing engines are relatively easy to tune. (Just use trial � and error to find what advance gives the most power at high RPM.) Some � single-stage distributor curves are so radical that they're only suited for � racing V8's (e.g. Mallory 29.014 with YT or YH advance curve change kit) � as shown in Figure 1:�

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

�

�

�

� The following graphs demonstrate the importance of selecting springs - � especially "paired" sets of springs. In paired-spring distributors, one � spring is typically longer and consequently it remains loose until over � approximately 1500 RPM. (Just to put ideas into the guys who are not � running a Mallory...!)�

�

�

�

� By changing the spring combination on a two-stage advance curve distributor, � one can achieve quicker advance to 1500 RPM, slower advance change at mid RPM, � and full advance from about 3000 RPM. Studying this illustration suggest that � a great distributor can be made without any sophisticated, digitalized or � twist button systems.�

�

�

�

�

�

Third Issue: What about "dwell"?�

� The dwell angle adjustment determines the duration of the spark. (Dwell is � normally set to 26-28 degrees on a stock Rover engine.) The only one way � to have a long lived spark is to reduce the points gap or to modify the � trigger's design (on an electronic ignition) - but I advise against doing � that! It is better to go to a dual point system and subsequently to two � sparks each cycle. For even more fireworks you must thrust your hand into � your pocket and order a digitalized ignition!�

� Most stock Lucas get about 27 degrees of dwell angle, whereas the Mallory's � vary by model as shown below:�

��

�

�

�

�

� The dwell angle adjustment determines the duration of the spark. (Dwell is � normally set to 26-28 degrees on a stock Rover engine.) The only one way � to have a long lived spark is to reduce the points gap or to modify the � trigger's design (on an electronic ignition) - but I advise against doing � that! It is better to go to a dual point system and subsequently to two � sparks each cycle. For even more fireworks you must thrust your hand into � your pocket and order a digitalized ignition!�

� Most stock Lucas get about 27 degrees of dwell angle, whereas the Mallory's � vary by model as shown below:�

�

| � | Point Gap | �Individual Dwell | �Total Dwell | �

| Dual Point Vacuum | �0.022 | �26 degrees | �33 +/- 2 degrees | �

| Single Point Mechanical & Vacuum | �0.018 | �29 degrees | �29 degrees | �

| Dual Point Mechanical | �0.022 | �26 degrees | �33 degrees | �

| Old Mallory Dual-Point | �0.018 | �17 degrees | �34 degrees | �

�

�

The following photo shows the Mallory spring kit (at top) and the Summit Racing kit (below). �

(Note: Summit kit part number SUM-G5212 fits GM HEI 74/79 non-computer distributors.)�

��

�

�

�

� Fourth Issue: Mechanical or vacuum advance?�

� I personally prefer mechanical advance distributors for their simplicity, � efficiency, and because the vacuum chamber presents a potential failure mode. � The risk of rupturing the rubber diaphragm is real when running a four-barrel� carb. One work-around is to install a Range Rover vacuum reducer (made in USA!) � in the line. The part number is: ERC 6997 and it can be found on any 3.5 / 3.9 � Discovery or Range Rover up to 1994.�

� Disclaimer: This page was researched and written by Jean Monfort. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�

�

�

�

�

�

� Fourth Issue: Mechanical or vacuum advance?�

� I personally prefer mechanical advance distributors for their simplicity, � efficiency, and because the vacuum chamber presents a potential failure mode. � The risk of rupturing the rubber diaphragm is real when running a four-barrel� carb. One work-around is to install a Range Rover vacuum reducer (made in USA!) � in the line. The part number is: ERC 6997 and it can be found on any 3.5 / 3.9 � Discovery or Range Rover up to 1994.�

� Disclaimer: This page was researched and written by Jean Monfort. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�