�

�

�

�

�

�

� Owner: Ed Olson

� City: St Paul, MN

� � Model: 1969 Triumph TR6

� Engine: 487 cubic inch Pontiac (4.15 bore 4.5 stroke)

� Conversion performed by: Owner

��

�

�

�

�

�

Ed Olson's 1969 TR6 with Pontiac V8 engine

� as published in British V8 Newsletter, Volume XV Issue 3, December 2007�� Owner: Ed Olson

� City: St Paul, MN

� � Model: 1969 Triumph TR6

� Engine: 487 cubic inch Pontiac (4.15 bore 4.5 stroke)

� Conversion performed by: Owner

�

| Engine: | �487 cubic inch Pontiac (4.15 bore 4.5 stroke).�

Lift: 477/477 Duration at 0.050: 231/226 at 0.050". | �

| Induction: | �Garrett TV75 turbo with a upgraded T88 compressor wheel.�

CSU Holley 850 carburetor. | �

| Exhaust: | �stainless log manifolds, 2.5" crossover, 5" exhaust. | �

| Ignition: | �HEI / MSD 6al. | �

| Cooling: | �Ron Davis radiator, Spal extreme 16" fan, PRP remote water pump. | �

| Transmission: | �T400 reverse pattern manual valve body with a transmission brake.�

9.5" PTC converter. | �

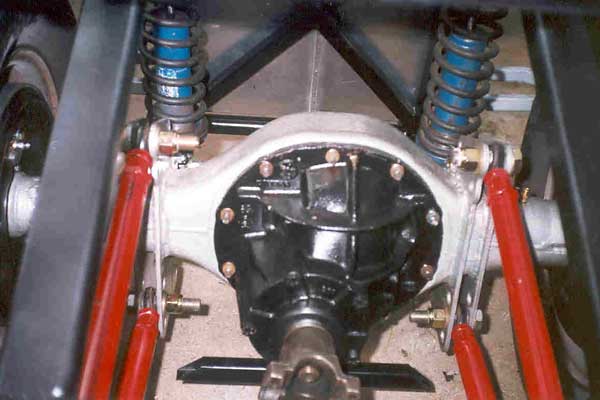

| Rear Axle: | �9" Ford, with 3:1 gear, Detroit Locker, and 31-spline axles. | �

| Brakes: | �(front) stock calipers with Hawk pads and drilled/slotted rotors. � (rear) Ford 11" drums. | �

| Wheels/Tires: | �Quick Time Pro tires: (front) 175/65/15's, (rear) 29/14.5/15. | �

| Weight: | �2550 lbs. | �

| Chassis: | �tube frame, and 102" wheelbase. | �

| Performance: | �the turbocharged Pontiac motor hasn't been tested yet, but with a �

previous 455cid engine this car achieved a 6.02 second, 120mph �

1/8th mile. | �

| Instruments: | �Autometer and stock. | �

| Audio System: | �the car had stereo pipes, but now with the single turbo I guess its back to mono! | �

| Comments: | ��

This is a home-built, father-son project. The first time the car saw �

the street it was a bunch of used parts, the motor and nitrous borrowed �

from my 68 Firebird. It was a 5 color Frankenstein with the doors just �

welded on, but it ran a 9.99s quarter mile. �

� My son and I built the frame and chassis, I had bars bent to patterns � and then did all the fish mouthing and fitting and tack welded the chassis � together. The final welding and tig welding was done by two of my friends � Brian and Mike, the car would never have been completed without their help. � � The doors were stretched 8", rear wheel openings moved rearward 5.5", � hood contours are made from steel from a TR4 hood and a fiberglass cowl � scoop.� � I had planned to have a Bondo party and just have a few friends over and � do a quick body work and paint job, but my friend Jim who does body work � made me a offer I couldn't refuse. Way too many hours of the two of us � working in my garage, and we finished up the job. It's a single stage PPG � color called "Nightwatch Blue" - the closest color PPG had to Triumph's � original "Royal Blue".� � My buddy Brian and I built the fuel cell. It has two sides with about � 8.5 gallons each: one for pump gas and one for race gas. � � The main frame sections were welded-up using a heavy steel table and a � bunch of C-clamps as a jig and then most of the rest of the chassis was � tacked together.� � A forklift makes welding up the chassis a lot easier! It keeps the welding � in convenient working positions. We also flipped the chassis over a couple � of times.� � The front suspension uses stock TR6 A-arms, steering rack mount, and rack. � QA1 adjustable coilovers with 450 lb. springs were installed. The 450 lb. � springs are a bit to light but are working for now. | �

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�