�

�

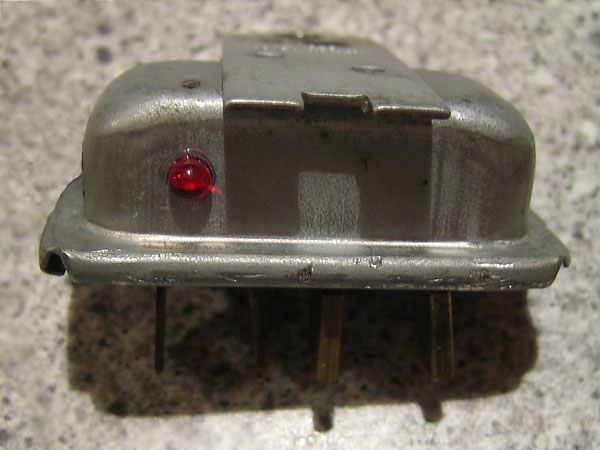

Upper left: the resistance-wire wrapped bimetallic element of an old-fashioned thermal Voltage Stabilizer.

�

Lower right: a solid-state electronic voltage regulator that can be used to replace it.

�

How To: Replace Your MGB's Thermal Voltage Stabilizer

�Install a Solid State Regulator Inside the Lucas Case

� as published in BritishV8 Magazine, Volume XVI Issue 2, October 2008�� text by: Curtis Jacobson

� photos by: Jim Miller�

�

� Notes: this article references MGB equipment, schematics, etc., and the information� may not be transferable to other vintage cars. �

�Background Information

��

Are you using original fuel level and coolant temperature gauges on your 1968�

or later MGB? Unlike modern aftermarket gauges, these two old-fashioned gauges �

are thermal ("bimetallic") devices. Their indicator needle is connected to a short �

beam constructed of two dissimilar metals. The beam is wrapped in resistance wire, �

which warms-up proportionally to the amount of electrical current passing through it. �

The gauge needle's position is determined by flexion of the beam due to the differing �

thermal-expansion rates of the two metals. To work properly, the MG fuel level and �

coolant temperature gauges need to be used with an external Voltage Stabilizer. �

(Note: the 1968-1972 MGB oil pressure gauge is also a thermal device. However, �

because of the unique nature of its sensor, it doesn't require a Voltage Stabilizer.) �

�

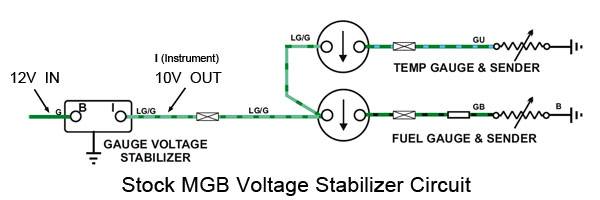

The schematic drawing below, "Stock MGB Voltage Stabilizer Circuit" illustrates �

how the fuel and temperature gauges are wired. In summary, the gauges are designed �

to receive a constant supply voltage of 10 Volts and it's the job of the Voltage �

Stabilizer to provide it. The fuel level and coolant temperature sensors, downstream �

of their respective gauges, are connected through their mountings to chassis/ground. �

The sensors act like variable resistors; their resistance changes with fuel level or �

coolant temperature respectively. �

�

The Voltage Stabilizer itself is nominally provided 12 Volts. However, we know from �

experience that the "voltage in" isn't so stable or predictable! A number of factors�

affect the supply voltage available, including: the battery's state of charge, the �

output of the generator or alternator at any given moment (which may be affected �

by engine RPM), and whether various loads on the system are "on" or "off". �

�

�

�

Regardless of how stable or predictable the 12 Volt supply is, the Voltage �

Stabilizer's purpose is to iron things out. As a generalization, you might say: "If �

the Voltage Stabilizer provides more than 10 Volts, both gauges will read high. If �

it provides less than 10 Volts, both gauges will read low." �

�

However, this generalization isn't strictly true - because the original MG Voltage �

Stabilizer doesn't actually regulate voltage at all! Instead, it cycles power "on" �

and "off" to achieve an average voltage (over time) of about 10 Volts. �

If you take an old-fashioned Voltage Stabilizer apart, you'll find a bimetallic �

element with a resistance wire wrapped around it (much like an automatic-reset circuit �

breaker, and not entirely unlike the gauges themselves.) Heat in the resistance wire �

causes the bimetallic element to bend. The bimetallic element actually bends back �

and forth quite rapidly, and in turn it rapidly opens and closes a set of contact �

points. Thus, it switches between a nominal supply voltage of about 12 Volts and �

a disconnected state (i.e. zero volts!) That suits old-fashioned, single-coil �

MGB gauges pretty well because they have a lot of mechanical dampening built �

into them. If your gauges are sufficiently damped, you may not see that their �

needles constantly wiggling as the Voltage Stabilizer chatters on and off; you'll �

only perceive the "average" readings they're showing you. �

�

By modern standards, thermal Voltage Stabilizers are inaccurate and inconsistent.�

Their output varies a lot between summertime and wintertime because their accuracy �

is affected by ambient temperature. Heat under the dashboard (e.g. when your windscreen�

defrosters are turned "on") can cause a significant shift in gauge readings. Output �

may also vary over the life of the Voltage Stabilizer as the bimetallic element �

fatigues, as internal contacts grow dirty, etc. If the resistance wire breaks, the �

Voltage Stabilizer will simply pass-through electrical current at continuous and �

unregulated voltage, so the old-fashioned thermal gauges will read high. �

�

If your Voltage Stabilizer is old or broken, or if you just want to improve the �

accuracy and consistancy of your fuel level and coolant temperature gauges, you �

may want to consider converting to a modern solid-state electronic voltage regulator.�

�

IMPORTANT NOTE: if you replace your original MGB gauges with aftermarket gauges, �

you should probably remove and NOT replace your old-fashioned thermal Voltage Stablizer. �

(Jumper across the Voltage Stabilizer connections.) Modern dual-coil gauges provides �

accurate information regardless of supply voltage, but they may not be adequately �

damped to accomodate the abrupt on/off cycling of a thermal Voltage Stabilizer. �

Shopping List

��

Solid state voltage regulators are inexpensive, but they may be difficult to find �

locally. The easiest places to purchase them are online. "Google" the part numbers �

to identify potential suppliers.�

�

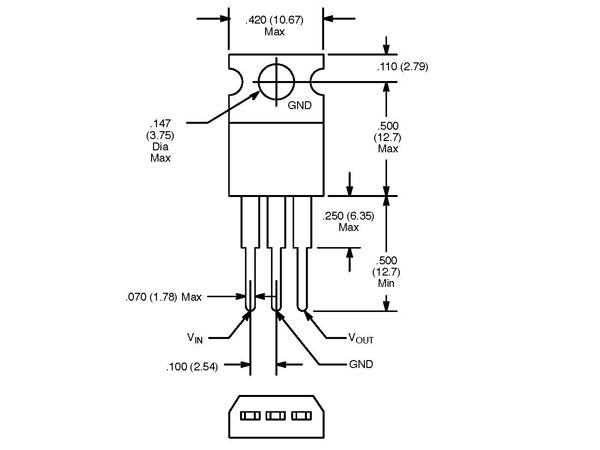

National Semiconductor's "LM2940T-10.0" and NTE Electronics' "NTE1953" are �

low dropout (LDO) solid-state voltage regulators. If you supply either of them �

with a DC voltage between 10.5V and about 30V, they will provide a constant output �

voltage of 10.0V. Similar to an old-fashioned bimetallic Voltage Stabilizer, they�

can't boost voltage: so if the supply voltage drops to below about 10.5V, these �

LDO's will "dropout" and simply pass through whatever supply voltage is available.�

�

Note: there are other alternative voltage regulators that could also be used. One �

example is Texas Instruments' part number "UA7810CKCS" (a.k.a. "7810" or "LM7810")�

which frankly you're probably more likely to find at your local Radio Shack. The �

main advantage of the National Semiconductor or NTE Electronics devices is their �

somewhat lower dropout specification.�

�

Also needed: just a few basics including a soldering iron, solder, about six inches of �

insulated wire, heat shrink tubing (or possibly electrical tape), etc.�

�

Optional extras: a small LED lamp and a 1000 ohm resistor. �

�

�

Solid State LDO Voltage Regulator Pin-Outs

�

left-to-right: VIN, "GND", VOUT

�

�

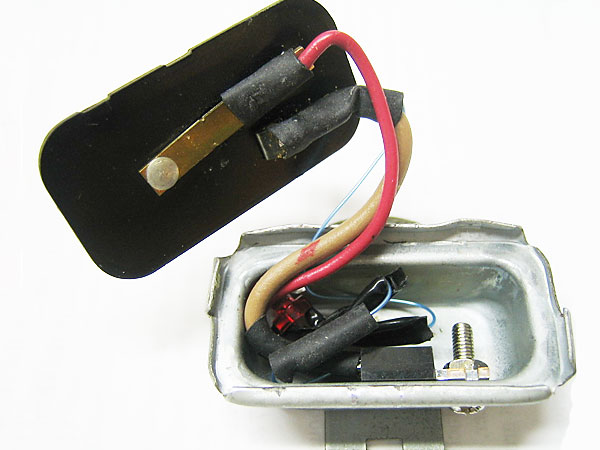

Make sure the solid state regulator is solidly grounded to the metal cover.

�

Directions

��

1. Disconnect the car's battery and remove the original Voltage Stabilizer �

from the car. (Note: the Voltage Stabilizer is mounted on the drivers-side �

firewall just above the steering column.)�

�

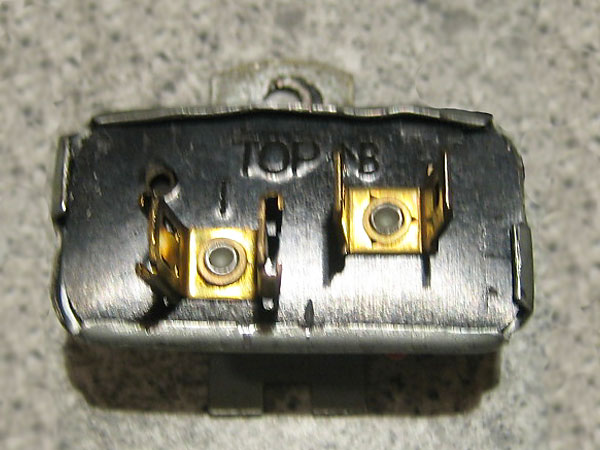

2. Open the voltage regulator by carefully prying back the tabs that clamp �

the metal cover to the plastic base.�

�

3. Cut and remove the old bimetallic regulator mechanism, being careful to �

leave enough of the two terminals for soldering wires onto them later. �

�

4. Prepare your solid-state voltage regulator by cutting off the center of �

its three terminals. (This terminal is nominally a "ground" connection, and it�

would be redundant with the mounting tab in our installation. They're connected �

internally...)�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

5. Using a short length of wire, jumper between the solid-state voltage regulator's �

VIN (12V in) terminal to the "B" terminal on the plastic base. �

Carefully solder both connections.�

�

6. Using a short length of wire, jumper between the solid-state voltage regulator's �

VOUT (10V out) terminal to the "I" terminal on the plastic base. �

Carefully solder both connections.�

�

7. The LED indicator is optional. Its purpose is just to show that the system is powered �

and grounded, and that the voltage regulator is functioning. The LED is connected at one �

end to the voltage regulator's 10V "OUT" terminal, and at the other end it's connected �

to ground through a 1000 Ohm resistor.�

�

8. To function properly, the solid-state regulator must be electrically �

well-grounded to the rest of the vehicle. Accomplish this by (first) connecting �

it to the voltage regulator's metal cover with a machine screw and nut. Note: �

the voltage regulator itself must in turn be grounded to the car by its mounting. �

If the fasteners are corroded or dirty, they should be cleaned at this time. �

�

�

Gently fold the edges of the metal cover back over the plastic base.

�

�

�

An optional LED simply indicates that the voltage regulator is powered, grounded, and functioning.

�

� Views expressed are those of the authors, and are provided without warrantee or guarantee.

� Apply at your own risk.�

� Photos by Jim Miller for British V8 Magazine. All rights reserved.�

� The schematic drawing "Stock MGB Voltage Stabilizer Circuit" was derived from an Advance Auto-Wire schematic,

� and was used here by permission.�

�

�