�

�

�

�

�

�

�

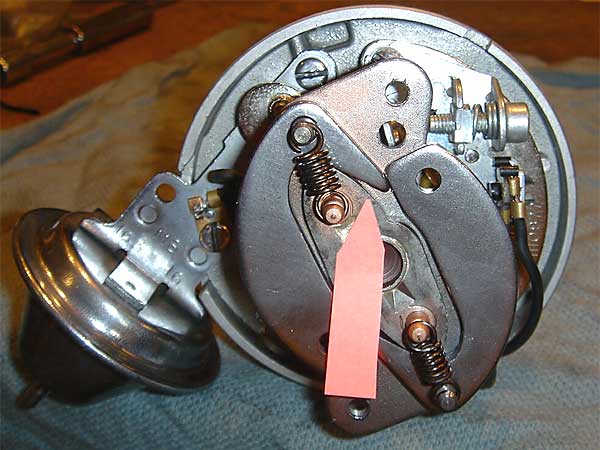

� Photo 1: Buick 215 Distributor, Cleaned Up and Torn Down

� �

� by: Jeff Schlemmer, proprietor of Advanced Distributors, LLC�

� For folks who are interested in recurving their own distributor, I'm going to � attempt to explain the basics of how to make adjustments and where they are made � to achieve a well rounded ignition curve. First things first: you must start � with clean, well-lubricated parts! Your ignition curve will never be consistent � if pivot points are binding from dried grease or if the bushings are sloppy loose.�

� Many versions of Rover and Buick distributors have been used over the years. � The unit shown in this article came from a 1961 Buick 215. It was not a low � mileage engine, and these parts looked like they would never be used again. � If you're working with similarly aged components, you'll likely find that the � whole works needs to be soaked in penetrant before you'll be able to remove � the shaft at all, due to dried oil build-up between the upper and lower bushings. �

�

�

� Photo 1: Buick 215 Distributor, Cleaned Up and Torn Down

�

Mechanical Ignition Advance

� as published in British V8 Newsletter, Volume XIV Issue 3, December 2006�� by: Jeff Schlemmer, proprietor of Advanced Distributors, LLC�

� For folks who are interested in recurving their own distributor, I'm going to � attempt to explain the basics of how to make adjustments and where they are made � to achieve a well rounded ignition curve. First things first: you must start � with clean, well-lubricated parts! Your ignition curve will never be consistent � if pivot points are binding from dried grease or if the bushings are sloppy loose.�

� Many versions of Rover and Buick distributors have been used over the years. � The unit shown in this article came from a 1961 Buick 215. It was not a low � mileage engine, and these parts looked like they would never be used again. � If you're working with similarly aged components, you'll likely find that the � whole works needs to be soaked in penetrant before you'll be able to remove � the shaft at all, due to dried oil build-up between the upper and lower bushings. �

�

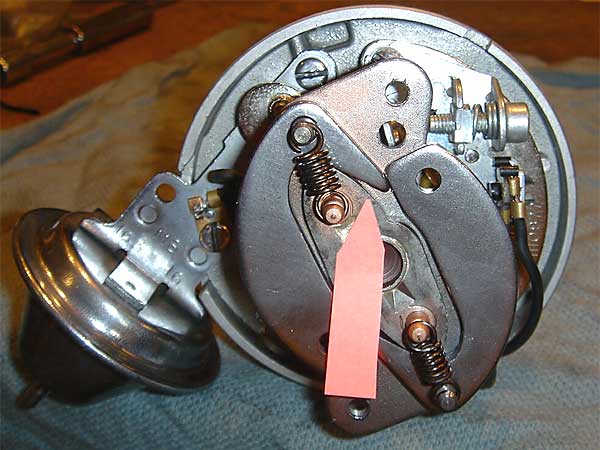

The amount of total advance offered by any distributor is adjustable, and in �

most cases 10-12 degrees of advance will get you in the ballpark. In Photo 2, �

the pink arrow highlights the adjustment mechanism (i.e. a pin which moves �

within a hole or slot). The width of the hole is the amount of advance that �

is allowed. The proper way to change the amount of advance available is to weld �

the hole smaller or to grind it larger. A few thousandths of an inch goes a �

long way! The hole shown here offers 17 degrees of advance. Obviously, it �

would also be technically possible to resize or reshape the pin. More commonly, �

when less ignition advance is desired, a bushing is slipped onto the pin and �

secured in place with a small circlip. Recurve kits for some models of �

distributor include a bushing or two for this purpose, but in the case of this �

Buick distributor the pin hangs upside down above the points. I believe it would �

be in the best interest of distributor to make a permanent repair, because a �

failed clip might result in a destroyed distributor.�

��

� Photo 2: Total Ignition Advance Adjustment� �

�

�

�

�

� Photo 2: Total Ignition Advance Adjustment�

�

�

The rate of mechanical ignition advance is determined by two important factors �

in these distributors. The springs are the most obvious, but the advance cam is �

equally important. In Photo 3, the peach colored arrow highlights the curved �

ramp that the weights follow as centrifugal force stretches the springs and �

allows advance. As the weight rotates across the length of the arched ramp, �

the radius of the curve determines the speed of advance onset. If the contact �

surface of the ramp starts basically "flat" for the first half of the weight's �

travel path, and then has a sharp radius for the second half, you'll get a fast �

onset of mechanical timing advance followed by a slow finale. In this case, �

however, we find a relatively even radius the entire length, so the curve will �

be smooth. This is what I like to see for most street-performance applications! �

In some later model distributors, you will find that the advance cam can be �

removed and replaced. Some Delco recurve kits offer replacement cams with �

different advance rates, or you can weld and grind the existing unit to achieve �

virtually any desired results.�

��

� Photo 3: Tuning Centrifugal Ignition Advance Mechanisms� �

� The selection of advance springs also affects how the ignition advance curve � relates to engine rpm. Replacement springs come in different strengths and � lengths, and as a practical matter there can even be significant variability � in springs that look quite similar. It's a great convenience to have a lot of � springs available. By using a precision spring force measurement tool and also � by measuring spring length, springs can be selected that will provide more � predictable performance results. �

� Obviously, the distributor shown here has two springs. It is often desirable � to select two springs that are somewhat mismatched. A lighter strength primary � spring (primary meaning the first spring to engage) used with a loose fitting � but relatively strong secondary spring will allow fast immediate advance at low � rpms, but a long, slow second half of the ignition curve. Compare this to a � pair of moderate strength matched springs and you can have a difference of 10 � crank degrees at mid-advance rpms, even though the start and finish points of � the curve stay virtually identical. �

� The general rule of thumb is that the ignition curve should start just after � idle, and be "all-in" around 3000 rpms. There are many factors that change the � engine's needs, such as compression ratio, type of carburetion, cylinder head � airflow, type and model of camshaft, as well as a long list of factors that need � to match the driver's needs such as fuel mileage, choice of transmission � (overdrive or not), highway driving, or drag race use. �

��

�

� Remember, when you chose an ignition curve for your engine, you should think of � the bigger picture. The amount of distributor advance should be figured from � the amount of total advance your engine can handle without losing power or � pinging, minus the amount of advance your engine can tolerate at idle. Most � drivers want a smooth idle, but others prefer just a little choppiness to � show off a high performance cam. Some folks don't care if it idles at all, � as long as it screams down the drag strip! A bit of playing with your current � distributor can help determine what will work best in your one-of-a-kind car: � find the best timing setting at idle, find the best timing setting for above-3000 � rpm driving, note the side effects at other rpms if there are any, and with all � these details considered you can map your own perfect ignition advance curve. �

�

�

�

�

� Photo 3: Tuning Centrifugal Ignition Advance Mechanisms�

� The selection of advance springs also affects how the ignition advance curve � relates to engine rpm. Replacement springs come in different strengths and � lengths, and as a practical matter there can even be significant variability � in springs that look quite similar. It's a great convenience to have a lot of � springs available. By using a precision spring force measurement tool and also � by measuring spring length, springs can be selected that will provide more � predictable performance results. �

� Obviously, the distributor shown here has two springs. It is often desirable � to select two springs that are somewhat mismatched. A lighter strength primary � spring (primary meaning the first spring to engage) used with a loose fitting � but relatively strong secondary spring will allow fast immediate advance at low � rpms, but a long, slow second half of the ignition curve. Compare this to a � pair of moderate strength matched springs and you can have a difference of 10 � crank degrees at mid-advance rpms, even though the start and finish points of � the curve stay virtually identical. �

� The general rule of thumb is that the ignition curve should start just after � idle, and be "all-in" around 3000 rpms. There are many factors that change the � engine's needs, such as compression ratio, type of carburetion, cylinder head � airflow, type and model of camshaft, as well as a long list of factors that need � to match the driver's needs such as fuel mileage, choice of transmission � (overdrive or not), highway driving, or drag race use. �

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

� Remember, when you chose an ignition curve for your engine, you should think of � the bigger picture. The amount of distributor advance should be figured from � the amount of total advance your engine can handle without losing power or � pinging, minus the amount of advance your engine can tolerate at idle. Most � drivers want a smooth idle, but others prefer just a little choppiness to � show off a high performance cam. Some folks don't care if it idles at all, � as long as it screams down the drag strip! A bit of playing with your current � distributor can help determine what will work best in your one-of-a-kind car: � find the best timing setting at idle, find the best timing setting for above-3000 � rpm driving, note the side effects at other rpms if there are any, and with all � these details considered you can map your own perfect ignition advance curve. �

�

�

But that's only part of the story. Once you have mechanical ignition advance all �

figured out, we can move on to vacuum-advance affects on performance and fuel �

economy. �

� Keep in mind that if you decide to recurve your distributor, there are many, � many decisions to be made and just as many adjustments. Patience will be of � the utmost importance. Many adjustments may need to be made several times before � they are perfect. If you think that making any of these repairs or curve � decisions is out of your comfort zone or skill level, there are still a few � experienced and skilled professionals who would be happy assist you. �

� Drive fast & take chances!�

� (Editor's note: "Effects of Vacuum-Advance on Performance and Fuel Economy" and � "Special Equipment and Techniques used by Professional Distributor Technicians" � will be subjects of future British V8 Newsletter articles by this author. Stay � tuned.) �

� Disclaimer: This page was researched and written by Jeff Schlemmer. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�

�

�

� Keep in mind that if you decide to recurve your distributor, there are many, � many decisions to be made and just as many adjustments. Patience will be of � the utmost importance. Many adjustments may need to be made several times before � they are perfect. If you think that making any of these repairs or curve � decisions is out of your comfort zone or skill level, there are still a few � experienced and skilled professionals who would be happy assist you. �

� Drive fast & take chances!�

� (Editor's note: "Effects of Vacuum-Advance on Performance and Fuel Economy" and � "Special Equipment and Techniques used by Professional Distributor Technicians" � will be subjects of future British V8 Newsletter articles by this author. Stay � tuned.) �

� Disclaimer: This page was researched and written by Jeff Schlemmer. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�