�

�

�

�

�

�

�

�

�

�

�

�

�

Ted Lathrop's Chevy 350 Powered 1976 TR6, by Fast Cars Inc.

��

(originally published in British V8 Newsletter, Volume 9 Issue 2)

�

�

By: Ted Lathrop

�

City: Wayland, MI

�

Model: 1976 Triumph TR-6

�

Engine: Chevy 350

�

�

How It Was Done

�| Engine: | �1972 Chevy 350 block, with 1996 Corvette aluminum heads. Bored 0.030" over. Camshaft�

from Competition Cams (0.454" lift, and 218 degrees) with hydraulic lifters. The Corvette�

heads were chosen because they had large valves, but rather small ports. This combination�

provides power and torque in the lower RPM range, as compared to heads with larger ports.�

Competition Cams roller rockers were used. The block was used because I just happened to�

have it laying around the shop. | �

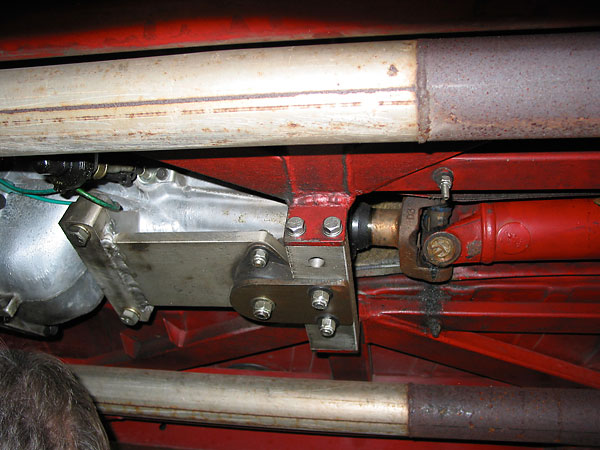

| Clutch/Flywheel: | �the clutch is a 10.5 inch unit from Centerforce. A McCleod hydraulic throw-out bearing is�

used along with the stock TR6 master cylinder. The bellhousing is a hydraulically formed steel�

piece from Lakewood. The steel plate provided with the bell housing was replaced with an owner�

fabricated aluminum piece for weight reduction.�

| �

| Transmission: | �BW T5 five speed from a 1982 V8 Camaro. Fifth gear was changed to a 0.80:1 ratio. With a 3.5�

rear axle, 0.80 works out perfectly for highway use. | �

| Exhaust: | �commercial stainless steel headers were purchased and extensively modified to fit. Corvette�

side-pipe mufflers were used, running straight under the car, and out the back. These produce a�

very pleasing, very mellow sound - no need for a stereo system! | �

| Driveshaft: | �a GM front section was mated to a Ford rear section, and the assembly was then balanced. | �

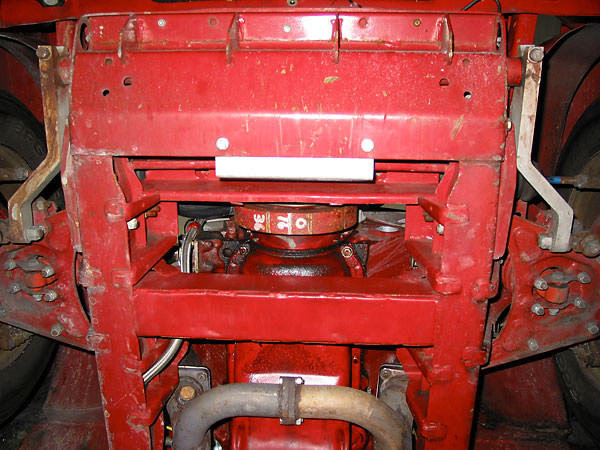

| Frame: | �the Frame is owner built. Portions of the original frame were used, such as the front�

suspension components and the side rails (although modified), but the majority of the frame�

is of my own design. The rear of the frame was built to accommodate a four-link suspension�

system and a Ford 9-inch axle. As you can see from the photo, the side rails were extensively�

modified and strengthened. The stock TR6 frame is rather flimsy, and flexes quite a bit. This�

frame design significantly reduces the flexing. | �

| Rear End: | �a Ford 9-inch unit was narrowed, and installed with 3.5 gearing. New axles were installed, with�

a five-bolt Chevy lug pattern. Combined with the tire size and transmission ratios, the 3.5 gearing�

works out just about perfect. Cruising at 70, the engine is turning 2480 RPM. At this RPM, there is�

plenty of power for passing without having to downshift into fourth. | �

| Front Suspension: | �the lower A-arm mounts were modified to move the pivot point inwards 3/8 inch to provide improved�

camber setting. The upper bushings were owner made of Teflon, lower bushings are Delrin. After�

several years of use, they still show no signs of wear. The shocks are Koni units. The front sway�

bar was taken from a sprint car, using owner fabricated aluminum control arms. | �

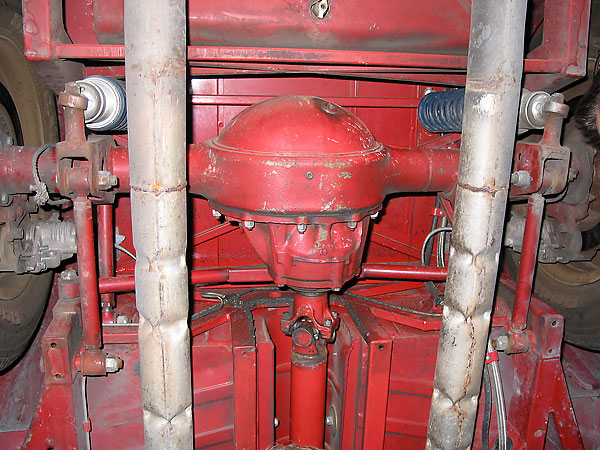

| Rear Suspension: | �Carrera coil-overs on a four link system. | �

| Brakes: | �Corvette disc brakes on all four wheels, front vertical link modified to accept Chevy spindles�

and hubs. | �

| Wheels/Tires: | �245/60/15 rear, 225/60/15 front. Lightspeed 3-piece wheels from Taylor wheel company, 8 inch in rear,�

7 inch in front. | �

| Cooling: | �Griffin aluminum cross-flow radiator, electric fan in a puller configuration. Front of radiator is�

fully shrouded, so ALL air passes through the radiator. Hood scoop is vented at rear. No cooling problems�

at all. | �

| Interior: | �stock gauges except for the fuel gauge, which is a BMW gauge with a TR6 face. The TR6 gauge would not�

read right with the BMW sending unit installed in the custom made fuel tank. Stock mechanical tach retained�

with an owner-built adapter to mate it to a mechanical tach drive Chevy distributer. Leather seats are�

from a BMW 318, year unknown. Dash was a gift from my wife Judy, and is a laminated dash with California�

fiddle back walnut veneer, made by Keller and Associates. Steering column is a tilt unit from an early�

Chevy van (no ignition locking mechanism). Many hours of custom work went into modifying the column and�

fabricating adapters to fit the TR6. | �

| Body: | �three piece rear bumper welded into one-piece. Ugly bumper over-riders eliminated front and rear, and holes�

welded shut. Side marker lights removed and hole filled. Unused holes under hood filled. Canvas top. Body�

area behind the seats and in the trunk was modified to allow room for the four-link suspension set-up.�

Custom aluminum fuel tank was made to fit the odd space left over. | �

| Electrical: | �Ron Francis Wire Works fuse block and wiring harness mated to stock wiring. Fuse block located on shelf where�

battery was originally located. Battery relocated to trunk. | �

| About the owner: | �Ted has spent a lifetime involved in the building and racing of circle track stock cars. This reflects that�

lifetime of experience. He is now "semi" retired and works out of his home shop in Michigan. He is currently�

developing a coil-over front suspension set-up for the MGB, and manufacturers a complete 8-inch Ford rear axle�

for the MGB as well. If you are interested in a BritishV8 conversion but don't feel you have the time or the talent�

for it, contact Ted and let him build it for you. See his ad on the inside front cover of this newsletter.�

| �

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�