�

�

�

�

�

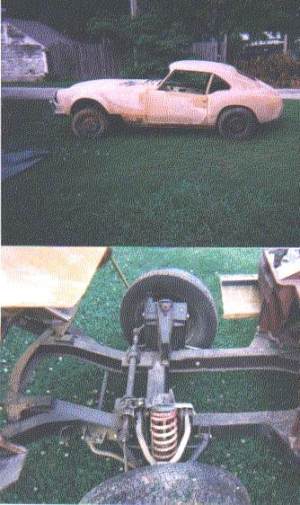

Roger Young's Triumph GT6, with Chevy V6

��

(as recorded by Dan Masters)

�

Roger wrote:

�

�

I contracted British Car Fever many years ago from a 1970 Lotus Elan +2. �

Owning and driving a Lotus is like being in love with an evil woman.�

The Lotus was cranky, picky, unreliable, she demanded constant attention�

and always let me down at the worst possible time. She sucked my bank account�

dry and left me stranded time and again. But, when the Lotus was good; she�

was SOOOOOO good. Her exhaust thundered, widows rattled as we passed by,�

the ground shook and the mortals quivered in terror as we exploded past them.�

Of course, such affairs never last and after 10 years of ownership and 18�

months of actual service we parted company.

�

�

It took several years for the pain of that relationship to�

heal. It took a couple more years for the bank account to recover. Then�

I decided to - DO IT ALL AGAIN. This time will be different; this time I'll�

build my own; a car with all the Lotus ground pounding thunder and none of�

the bad stuff. The Triumph Spitfire/GT6 looked like the best starting place.�

The Spit is light, the body proportions are good, I love the clam shell�

bonnet; it's a good, simple design. All that's needed is to fix the engine,�

transmission, electrical, hydraulic and rear suspension problems, in other�

word - throw them away and splice in the appropriate American components.

�

�

I found my GT6 (her name is Lola) in 1996 on the back row of a seedy used car lot. �

She was painted school bus yellow, had a stripped differential and no half shafts. �

Her body was fairly straight; she showed no signs of rust, and had 83,000 miles �

on her odometer. The dealer wanted $500 for her and urged me to act now because �

he had another buyer coming in to pick up the car in a day or two. I told him �

she was only worth $300 to me. A week later I towed Lola home - for $300. �

My journey started with the decision to flare the rear fenders, from there things �

got a little out of hand.�

�

Here is a list of the body modification made to date:

�

- �

- Rear fenders have been flared 4" per side (inspired by the AC Cobra) �

- Front fenders have been flared 2 1/2 inches per side (inspired by the AC Cobra) �

- License plate recess has been cut out and replace with a smooth panel (inspired by the '58 Vette) �

- Hatchback was welded down and a proper boot lid fabricated (inspired by the '59 Ferrari 250 GT. Hatchbacks are for Pintos!) �

- Roof rain channels were welded and trimmed smooth (just because) �

- Rear quarter panel window were recontoured to match the roof line (they looked goofy) �

- Frame and bonnet have been stretched 7" (improves the overall proportions of the car and allows easy installation of a V8) �

- Bonnet nose has been rounded (inspired by the Ferrari 275 GTB - everything else on Lola is roundy and curvy) �

- Hood bulge has been raised and extended back the full length of the bonnet (inspired by the '70 Chevelle - carb clearance and cold air intake) �

- Front bumper has been split (inspired by the Ferrari 275 GTB - my bumper was bent in the middle) �

- Windshield frame has been welded-in permanently and filled (just because) �

�

� Lola currently has an Opel GT rear axle. The Opel axle was� the right width, has a good basic design and is strong enough to handle a� V6 engine. Installing it required extensive frame and floor pan modifications.� I'm not unhappy with the Opel axle, but in retrospect it would have been� easier to fabricate a new frame and use a Datsun 240Z rear end.

�

� The frame stretch left room for a V8, but I think a high winding� V6 better matches the car's character. I used a Chevy 2.8L V6 engine from� a Citation and mated it to a 5-speed transmission from a Chevy S10. Installation� required trimming the frame to clear the starter and minor frame modifications� around the transmission. Cooling is handled by an '84 Camaro radiator, it� mounted vertically with half inch of hood clearance. My choice of engine/transmission� combination was based primarily on what I had lying around.

�

� I had constant problems with the hydraulic and electrical� systems on my Lotus and I was determine to eliminate everything Lucas and� Girling from the Triumph. I found Datsun components to replace the brake� master cylinder, clutch master cylinder and clutch slave cylinder. The Japanese� obviously copied Girling designs, the Datsun parts look similar to their� Girling counterparts and the bore and stroke dimensions are identical. The� brake and clutch master cylinders bolted in after I elongated the flange� boltholes with a file. The clutch slave cylinder required and adapter plate� to bolt up. Hood clearance demanded that I build new fluid reservoirs, with� I made using PVC pipe fittings. The rear brakes are Opel and I'm still working� on the front disk brake solution.

�

� To cure the electrical problems I adapted Ford light sockets� into the Triumph light housings and I replaced all the dash switches with� industrial grade toggle switches. The switches are rated for 30 amps and� eliminate the need for relays. I fabricated a simplified wiring harness� using a '57 Ford wiring diagram as a guide. I replaced the three-piece� wooden dash with a single oak panel. The oak does not splinter when sawing� or drilling out the gauge holes; I found it much easier to work than plywood.

�

� The car is starting to come together relatively quickly now,� in retrospect I did a lot of things right and I did a lot of things wrong.

�

� Stretching the wheelbase turned out to be very right. I know several� people have stuffed V6 engines into the stock Spit - but I don't see how.� The added length improve the cars proportions, the engine just fell in,� it cured the exhaust system problem (side pipes) and improved the weight� distribution.�

� �

�

I should have stretched the rear fender flares out 5 inches per side - even�

with a 4 inch flare the wheel wells are a little tight. I could not have taken�

the front flares out any further - any more would have looked odd.

�

�

My original decision to make all the body modifications in steel turned�

out to be a mistake. I know some people have the skill to fabricate body�

panels in steel - but I'm not one of those people. The flanged body panels�

Triumph uses actually lends it self to using glass panels. I believe the�

body substructure will provide adequate support for the glass panels. I�

wasted a lot of time and effort.

�

�

Keeping the original frame was a mistake. The stock frame is stamped�

10-gauge sheet metal and the factory welding is hideous. I have a new frame�

on the drawing board. The new frame is fabricated of 3 inch channel iron and�

is substantially stronger than the stock unit. Using the channel allows�

an additional 3 inches of width for the engine/transmission. The basic layout is�

essentially a copy of the original central backbone fame, but my new design�

incorporates doorsill outriggers resulting in a combination perimeter/central�

backbone chassis. This increases body stiffness and allows the floorboards�

to be incorporated into the frame. I hope to use a stock Datsun differential�

and rear suspension. Using the Datsun rear end will increase the rear track�

width (the stretched fender should allow it) and will require widening the�

front track to match. I will eventually install this frame in my car.

�

�

Using the little Chevy engine was a good choice. Installing it was�

actually the easiest part of the process. Lola is technically a mid-engine�

car with her engine mounted just behind the centerline of the front axle.�

The stock air cleaner fits with a half inch left to spare and I believe the steering�

column is going to just sneak by the exhaust manifold. Piecing together�

the engine and transmission was a definite mistake. I've got adapter plates�

to mount the starter to the engine, I've got the GT6 shifter mounted to the�

Chevy transmission, custom bent tubes to route the water to the radiator,�

the list goes on and on. Just strip everything from a Camaro and be done�

with it. The Camaro engine comes with (or will accept) a single wire distributor�

with integral coil, single wire alternator, a 2 barrel Rochester carb, and�

the shift knob location is close to the stock Triumph location. I've also�

discovered the Camaro air conditioning compressor tucks in neatly above the�

intake manifold with adequate hood clearance.

�

�

I am currently doing the final fitting and finish sanding on the body�

panels. I moved the battery to the boot, leaving space on the firewall to�

install an A/C unit. The exhaust system plumbing is the last major project.�

With luck, Lola should see the road this year.

�

�

p.s. I get odd reactions from people when I describe my little British car. �

My wife, co-workers, friends and family are unable to decide whether I'm: �

(a) simply stupid (b) slightly insane or (c) both.�