�

�

Derek Costello's 1974 Triumph TR-6 with Ford 302cid V8 Engine

� � Owner: Derek Costello� � City: Niagara Falls, Ontario

� Model: 1974 Triumph TR-6

� Engine: Ford 302cid V8

� Conversion by: owner

�

How It Was Done

�| Engine: | �rebuilt Ford 302 V8.�

Edelbrock E-Street aluminum cylinder heads.�

Edelbrock camshaft.�

Roller lifters.�

Edelbrock Performer 289 low-rise intake manifold.�

Edelbrock 500cfm carburetor.�

HEI distributer.�

AC Delco 8mm silicone spark plug wires.�

Ford Racing valve covers.�

| �

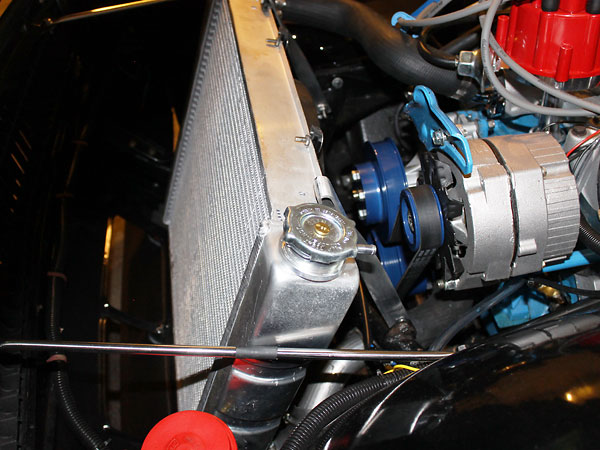

| Cooling: | �19" by 24", 3-row, cross-flow, aluminium radiator.�

16" Kenlowe electric fan.�

| �

| Exhaust: | �Speedway block hugger headers.�

Stebro twin-pipe exhaust.�

| �

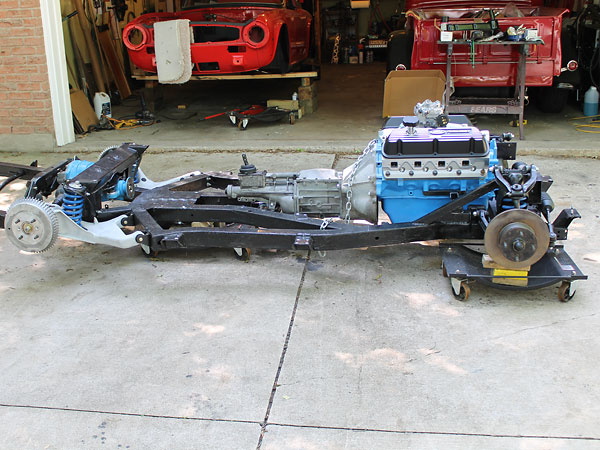

| Transmission: | �T5 5-speed.�

Tilton hydraulic throw-out bearing.�

| �

| Rear End: | �Good Parts Nissan / Infiniti Q45 limited slip differential.�

3.7:1 gear ratio.�

CV jointed axles.�

| �

| Frame: | �totally rewelded, with many diagonal braces added.�

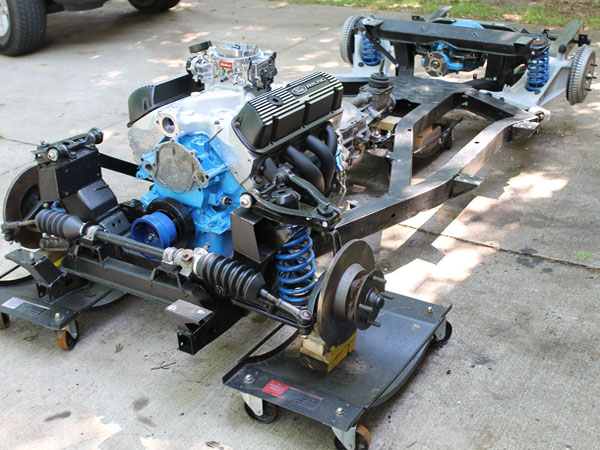

Fabricated motor mounts to locate the engine lower and further back than many other conversions.�

| �

| Front Suspension: | �300 lbs./inch springs.�

7/8" ADDCO sway bar.�

Four Borgeson steering U-joints to get around engine. | �

| Rear Suspension: | �375 lbs./inch springs.�

Telescopic shock absorbers on fabricated brackets. | �

| Brakes: | �(master) stock Triumph TR-6 cylinder and booster. � (front) Wilwood 4-pot calipers and solid rotors. � (rear) aluminum drums. | �

| Wheels/Tires: | �Konig Rewind aluminum wheels (16"x7", with zero offset).�

General Altimax RT tires (215x16). | �

| Interior: | �biscuit colored vinyl interior. | �

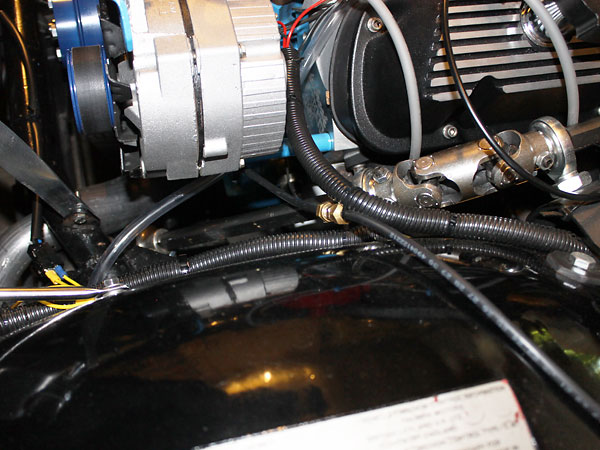

| Electrical: | �battery relocated to the trunk.�

Fuel pump relocated to the trunk. | �

| Completed: | �this project took about 11 months to complete. | �

| Comments: | �I hope my pictures are a helpful to others contemplating a Ford V8 for their TR-6.�

I pored over "British V8 Magazine" many times during this project. | �

Engine Installation

��

�

Edelbrock E-Street aluminum heads with HEI distributor and Speedway block-hugger headers.

�

�

An Edelbrock Performer low rise intake manifold leaves one inch of clearance above the air cleaner.

�

�

Four Borgeson U-joints route the steering around the engine.

�

Even with this arrangement, steering feel is very light.

�

�

19" by 24", 3-row, cross-flow, aluminium radiator with 16" Kenlowe electric fan.

�

Front Suspension

��

�

Wilwood four-pot aluminum calipers fitted to Triumph spindles. Upgrade to 1/2" x 20 wheel

�

studs. ADDCO 7/8" sway bar mounted on a 4" by 1/4" plate bolted to the bumper supports.

�

Rear Suspension

��

�

"Alfin" (aluminum finned) brake drums are mounted on Good Parts hubs with 3/8" studs.

�

Custom fabricated steel 1-1/2" by 1-1/2" tube shock mounts.

�

Interior

��

�

"The dashboard has been ground down and refinished with my own graining and lots of Varathane.

�

Assembled with TR-6 gages with domed glass crystals and chrome bezels from a Triumph TR-3.

�

I rebuilt all the Triumph gages and converted the mechanical tach to electronic by changing

�

the mechanism for an electronic unit from Auto Meter. (This was a simple change over.)"

�

�

Custom turned/polished stepped aluminum rings fit dashboard cooling vent openings.

�

�

A leatherette covered aluminum box accommodates the 6" rearward placement of the T5 transmission.

�

�

Biscuit colored vinyl interior.

�

The Before Picture

��

�

The original Triumph engine and transmission combination weighed 24 pounds more

�

than the newly installed Ford 302 V8 (with aluminum heads and 5-speed gearbox).

�

In Process Photos

��

�

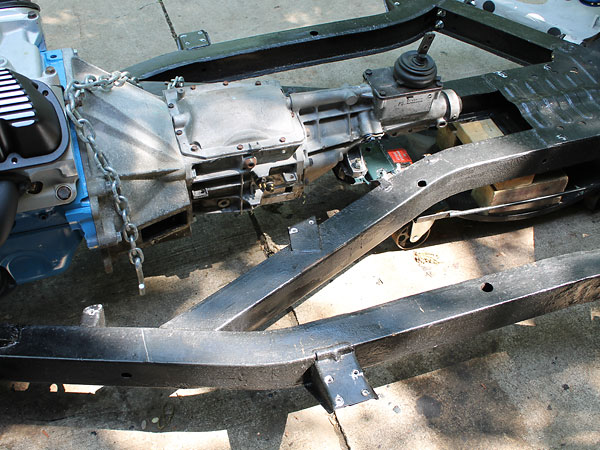

Engine and transmission has been fitted to the Triumph frame.

�

�

This photo shows how far rearward the engine has been placed.

�

�

Rear transmission mount details.

�

�

Nissan / Infiniti Q45 differential.

�

Firewall Modifications

��

�

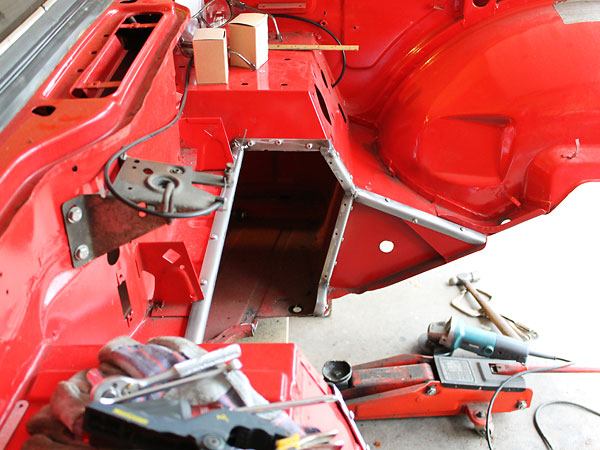

Original battery tray and transmission tunnel of the stock TR-6.

�

�

After cutting and framing the Triumph for the large transmission tunnel.

�

�

A side shot of the new transmission tunnel.

�

�

Newly welded 16 gage steel transmission tunnel.

�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

Exterior Modifications

��

�

New bumpers were installed lower and closer to the body for improved appearance.

�

To facilitate bumper relocation, parking light holes were filled in.

�

Custom Fiberglass Transmission Cover

��

�

The original Triumph TR-6 transmission cover was made out of cardboard.

�

�

Derek applied foam and plastic to the original cardboard cover to build it up into

�

a mold over which a larger (though lightweight) fiberglass tunnel could be made.

�

�

Derek sprayed adhesive over the built-up cover and then applied a layer of aluminum foil.

�

�

Three layers of resin and fiberglass cloth were applied over the foil. Once hardened,

�

the new molded fiberglass transmission tunnel was pulled away from the foil.

�

�

Aluminum H-form member before cutting and shifting the gear shift projection

�

lower and also rearward six inches to suit the new T5 5-speed.

�

Exterior

��

�

Konig Rewind aluminum wheels (16" x 7" with zero offset). General Altimax RT tires (215x16").

�

�

DuPont Centari acrylic enamal in "Pitch Black" (color code 99A).

�

�

TR3 stable mate.

�

�

Did you enjoy this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�