�

�

Steve Sanett's 1962 Daimler SP250 with aluminum Chevy 427 V8

� as published in BritishV8 Magazine, Volume XVII Issue 1, July 2009�� Owner: Steve Sanett

� � City: Chatsworth, CA

� Model: 1962 Daimler SP250

� Engine: 427cid Chevy/Dart aluminum V8

� Conversion performed by: owner�

�

Background Information

��

Daimler was a British specialty car manufacturer. They built their first car in 1896.�

Historically, Daimler was probably best known as the preferred supplier of limousines �

to the British royal family. �

�

The company's name has caused much confusion over the years. In Daimler's early days, �

they built their own engines using patents licensed from the more famous German �

company of the same name. However, in terms of actual ownership and management, the �

two companies were entirely seperate. �

�

Toward the end of a long series of distinctive up-market cars, Daimler introduced a �

fast new roadster called the "Dart" at the 1959 New York Motor Show. The Daimler Dart �

was met with interest, but the model name had to be abandoned because Dodge had already �

trademarked it for their hugely successful economical compact. Daimler re-named their �

Dart model "SP250" for the U.S. market. (They continued using the name "Dart" in �

other markets.) �

�

The SP250's fiberglass body was mounted on a tubular steel, ladder chassis. In 1960 �

Daimler was acquired by Jaguar. Jaguar frankly felt that the original Daimler SP250 �

chassis was crude and dangerous, so they immediately redesigned it. They even went so �

far as to have all unsold, exported SP250's shipped back to England to be torn down and �

rebuilt. The improved SP250 was designated "B Series". �

�

All Daimler SP250's were built with 2.5L V8 engines which produced about 140 BHP and �

featured aluminum cylinder heads, hemispherical combustion chambers, two valves per �

cylinder, and a single camshaft. By many accounts this was an excellent engine, but �

it had no hope of being popular in the power-hungry U.S. markets due to its small �

displacement, high cost, very limited service and parts support, etc. Performance �

enthusiasts had to modify the engine to get the most out of it: from stock it had a �

compression ratio of only 8.2:1. At about 419 pounds, the Daimler V8 weighed over 100 �

pounds more than a 3.5L Buick/Rover V8.�

�

When production of the SP250 sports car was cancelled at the end of 1964, only 2654 �

had been sold. Although the cars are rare, it's not uncommon to find SP250 engine �

conversions, or to find potential project cars offered for sale without engine.�

�

The Daimler 2.5L engine was somewhat more successful than the SP250 car. It was used �

in a Daimler-badged variant of the Jaguar "Mk II" saloon through 1969. Total production �

of the engine surpassed 20,000 units. Reportedly, after Jaguar merged with BMC the �

Daimler V8 was considered for use in other sports cars, including an MGB variant.�

�

Steve Sanett imagined what an SP250 might be like with comfortably more than �

250 percent more engine displacement, power, and torque. �

�

�

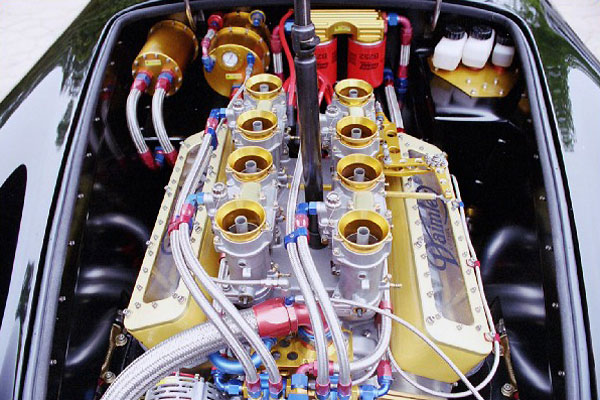

Dart all aluminum 427cid Chevy engine block with Air Flow Research 225cc heads.

�

How It Was Done

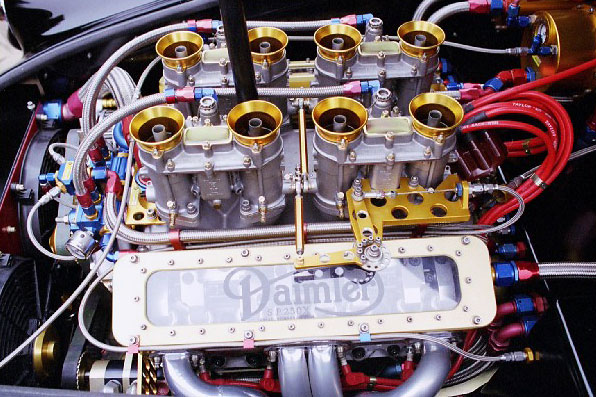

�| Engine: | �Dart all aluminum 427cid Chevy with Air Flow Research 225cc heads and titanium �

valves. J.E. pistons (12.5:1), Carrillo rods, Cola crankshaft, Jessel belt drive.�

Solid roller cam by Comp Cams (252 degrees intake, 248 degrees exhaust, at �

0.050"/ 0.610" valve lift. 108 degree lobe separation.) MacKay magnesium �

intake manifold. 48IDA Weber carbs bored to 51mm with custom 46mm secondary�

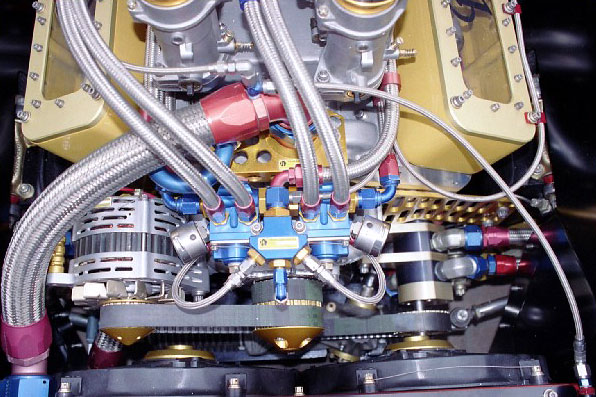

venturis. Mallory Super Mag (magneto transformer) 80-amp ignition. Aviaid �

4 stage dry sump oiling system. Custom billet aluminum valve covers with clear �

Lexan inserts back-engraved with the Daimler logo. Custom billet aluminum surge �

and breather tanks. | �

| Cooling: | �Ron Davis custom aluminum radiator, plumbed with dash 24 Aeroquip hose and fittings.�

Dual electric fans. | �

| Exhaust: | �custom polished stainless steel headers with 1.750" primaries. 3.5" stainless �

steel side pipes. | �

| Transmission: | �Borg Warner Super T10 close-ratio 4-speed. (Top gear is 1:1). Custom driveshaft. �

Tilton triple organic clutch disc. Aluminum flywheel. Hydraulically actuated. | �

| Rear Axle: | �Speed Way Engineering quick change with Detroit Locker and 3.11:1 gears. | �

| Front Suspension: | �modified Daimler double wishbones (converted to Heim joints). �

Koni double adjustable aluminum coilover shock absorbers. �

Custom anti-sway bar.�

Converted to rack and pinion steering. | �

| Rear Suspension: | �Koni double adjustable shock absorbers. | �

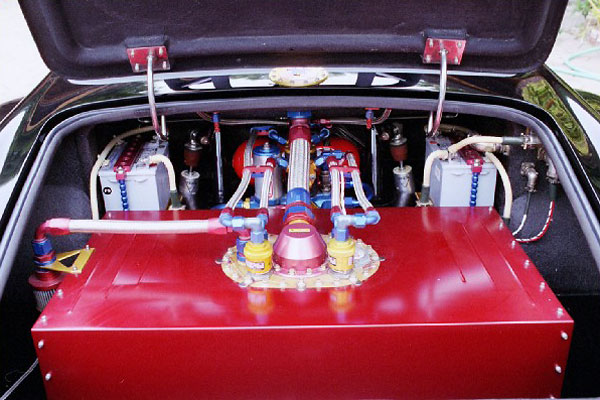

| Chassis: | �re-welded all factory tubing. Surprisingly, we were able to re-use the original�

(Daimler V8) engine mounts. The rear section of the frame was modified for stiffness�

and also to accept telescoping shocks. The upper �

shock mountings are actually mounted to the roll bar in the trunk area. An ATL fuel cell was installed in �

a custom aluminum enclosure. Custom billet aluminum gas cap.�

All bolts are 12-point MS21230 Mil spec. | �

| Body: | �all quarter panels were pulled. The rear quarter panels were vented. (See photo.)�

All handles were shaved. Stainless steel trunk and hood hinges were custom �

made. Cobra reverse hood scoop. Front blinkers were removed. Front grille�

was reshaped. | �

| Interior: | �custom aluminum dashboard. Sparco (Kevlar composite) seats with 5-point �

Sparco harnesses. Door panels and dashboard custom upholstered in Connely hide. �

Custom roll hoop with Petty bar. | �

�

| Wheels/Tires: | �PS Engineering "Cobra" (Halibrand style spline drive aluminum wheels with �

tri-wing knock-offs) 15x8.5 front / 15x10.5 rear. Goodyear "Blue Streak" �

racing tires. | �

| Brakes: | �Girling aluminum "18-4" 4-piston calipers and 11.5x1.25 vented rotors. | �

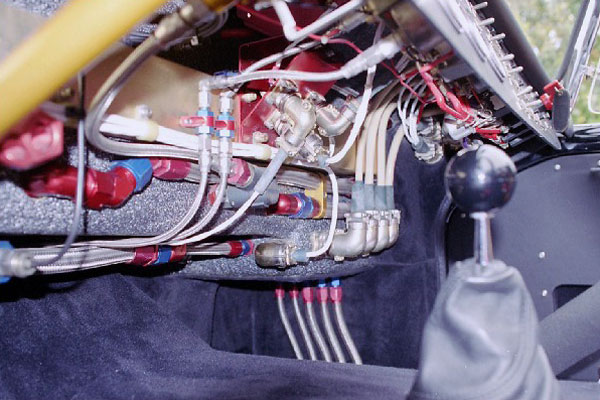

| Electrical: | �custom wiring featuring Teflon insulated silver wire and aluminum �

MIL STD connectors. All switches feature silver contacts. MIL STD �

aircraft circuit breakers.�

Stewart Warner mechanical gauges. Jones Motrola Corp. mechanical tachometer. �

Dual SLA (sealed lead acid) batteries on custom aluminum battery trays. �

Onboard fire suppression system. | �

| Performance: | �engine dyno specs are 540 HP at 7100rpm, 575 LB FT torque at 4150rpm.�

52% / 48% weight distribution. Engine was moved back about six inches from �

the original (Daimler V8) location. 0-60mph in 3.3 seconds. | �

| Weight: | �2400lbs. | �

| Completed: | �driven about 1020 miles since the conversion was completed in 2000. | �

| Comments: | �building this car was a 10 year project and a substantial learning experience.�

Our concept was to show what might have been if Daimler had wanted to go�

racing against Shelby in the 1960's. The project touched on many aspects of�

automotive and aerospace technology - all merged into an old British car!�

It was fun, tedious, and VERY expensive, but worth every penny and every�

minute spent. | �

�

�

48IDA Weber carbs bored to 51mm with custom 46mm secondary venturis.

�

�

Custom aluminum valve covers with clear Lexan inserts.

�

�

Aviaid 4 stage dry sump oiling system.

�

�

�

ATL fuel cell installed in a custom aluminum enclosure.

�

�

Vents have been carved into the rear fenders, outboard of the tail lamps!

�

�

Custom door panels and dashboard. Modern Sparco composite seats.

�

�

�

Stewart Warner mechanical gauges. Jones Motrola mechanical tachometer.

�

�

Teflon insulated silver wire and aluminum MIL STD connectors.

�

�

Extensive Aeroquip plumbing, as required for the mechanical gauges.

�