�

�

Laurie Houghton's 1973 MGB with Rover 3.9L V8

� as published in BritishV8 Magazine, Volume XVII Issue 1, July 2009�� Owner: Laurie Houghton

� City: Adelaide, South Australia

� � Model: 1973 MGB

� Engine: Rover 3.9L V8

� Conversion by: owner

�

| Engine: | �Range Rover Discovery 3.9L V8 with 8.1:1 compression ratio. Aftermarket cam, �

slightly improved from the standard grind (280 degree duration and 0.450" lift.)�

Deeper baffled Range Rover sump and larger bore oil pick-up pipe.�

Modified Rover (3.9) intake manifold to fit under the bonnet. �

Carter lift pump to a fuel surge tank mounted in the RH side battery box. �

Bosch high pressure EFI fuel pump. �

EFI injector and ancillary wiring are from a Discovery loom. �

Haltech F9 programmable electronic fuel injection computer. �

Standard electronic SDI distributor. | �

| Cooling: | �custom aluminium radiator and single electric cooling fan. | �

| Exhaust: | �4-into-1 headers exiting through the inner guards. Single collector and �

2.5" inch pipes into dual mufflers. | �

| Transmission: | �Toyota W58 5-speed with 0.78:1 5th gear. Australian made "Dellow" bell housing.�

Standard Range Rover clutch and pressure plate. Fork type release. Toyota slave �

cylinder. Custom built Toyota-to-Ford driveshaft. | �

| Rear Axle: | �Ford 8 inch center section with 3.27:1 gears and limited slip differential,�

married to MGB (Salisbury) tubes. Custom axle shafts. | �

| Front Susp.: | �650 lb. lowered competition springs. 7/8" diameter sway bar. | �

| Rear Susp.: | �stock MGB roadster springs with Koni telescopic shocks, anti-tramp rods, �

and a Panhard rod. | �

| Brakes: | �Front: BMW Mini Cooper S vented brake rotors (294mm outside diameter�

by 22mm thick) with Nissan GTR (R33) 4-piston aluminum calipers.�

(As originally reported in 2009: Peugeot 504 vented 273mm x 20mm rotors�

with Rover SDI 4-piston calipers.) � Rear: Mitsubishi rotors, used with Nissan R31 calipers. MGB hand brake lever. | �

| Wheels/Tires: | �(circuit/hillclimb) Volk Racing 15 x 6.5 wheels with Silverstone 195x55x15 road legal race tyres. � (street) 15 x 6.0 Nissan Silvia wheels. | �

| Chassis: | �firewall mods to suit the V8 engine and steering column. Custom fabricated and �

installed (rubber bumper type) radiator supports and V8 engine mounts. �

Enlarging radiator "splash panel" area. | �

| Body: | �"Sebring style" front and rear "valances". | �

| Interior: | �roll hoop and 6-point racing harness for the driver seat. Standard MGB �

instruments except for a VDO electronic speedometer. | �

| Weight: | �1980 pounds. | �

| Performance: | �120 KW at the rear wheels. 394NM Torque on 98 octane unleaded pump fuel. �

The engine is rev-limited at 5400rpm by the computer. At the �

Philip Island International racing circuit in Victoria I was reaching �

5100 rpm in 5th gear on the main straight at the braking point for turn 1, �

estimated 130mph. | �

| Completed: | �January 2008. (Only 200 - 250 miles driven so far, since it's only used at competition events.) | �

| Comments: | �I started with a 1973 MGB, imported from California in 1993. Having the �

engine low in the engine bay introduced a problem with the steering column:�

the original collapsible part under the dash had to be shortened, a new �

firewall "pocket" made and welded-in and a rubber bumper long shaft rack �

installed. There is still very little clearance between the steering shaft �

and the rear extractor from #8 cylinder. In hindsight I would have angled �

the steering column lower and altered the angle of the steering rack mounts.�

This would have meant modifying the RH engine mount. Other than that, it's �

pretty much a breeze. �

� I already had the 5 speed Toyota gearbox behind the 4 cylinder engine, so � I used it for the V8 too. My preference would have been a Tremec T5 with the � 2.95:1 first gear, which would be better for hillclimbing, but that's the only reason.� � My next project is fitting 20mm larger diameter front rotors from the � Cooper-spec BMW Mini, Nissan 300 ZX 4 piston callipers, (much lighter than � the Rover 4-pots) or AP if I can afford them, and twin brake master cylinders � with bias-bar adjustment. (I'm currently using the original dual circuit master � cylinder with a Tilton proportioning valve on the rear brake circuit.)� � The low compression engine was supplied here in OZ for some Rover Discoverys. � Maybe one day when the engine needs an overhaul, I'll fit high compression� pistons to raise the compression. When I had the 2-litre 4-cylinder, there � was always something to fix! When I installed the 3.9, I wanted a trouble-free � engine. The performance improvement over the 4-cylinder is still tremendous.� � | �

�

�

The Haltech programmable fuel injection system doesn't require a hot-wire airflow sensor.

�

�

The Haltech EFI control unit is mounted on a drop down panel under the glove box. You can see

�

the multi-pin connector by the rubber firewall plug in the engine bay photo above. The MAP

�

sensor is to the left of it (by the bonnet hinge) next to the heater, which is not connected.

�

�

Installing "RV8 style" through-the-wing headers has the additional benefit of venting hot air from

�

the engine compartment. Heat shields help to keep the pedal box and brake system cool.

�

�

�

This photo shows body modifications required when relocating the radiator forward of the anti-sway bar.

�

�

To accomodate a very low mounting of the engine, I shortened the collapsible part of the steering

�

column (under the dashboard) and rebuilt the firewall "pocket". A rubber-bumper (longer) steering

�

rack was installed to relocate the u-joint rearward and create clearance at the #8 cylinder.

�

�

�

�

�

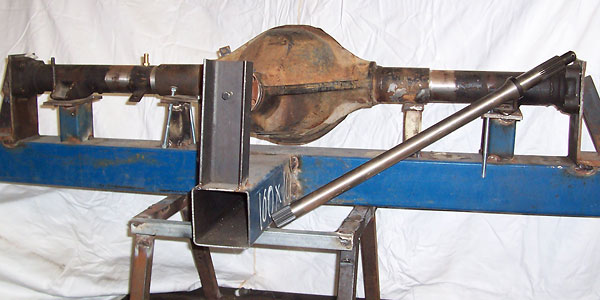

Ford 8 inch center and limited slip differential, married to MGB (Salisbury) tubes.

�

�

Anti-tramp bar and telescoping shock.

�

�

Panhard rod mount.

�

�

Reinforcements in the boot floor for the Panhard rod installation.

�

2010 Updates

��

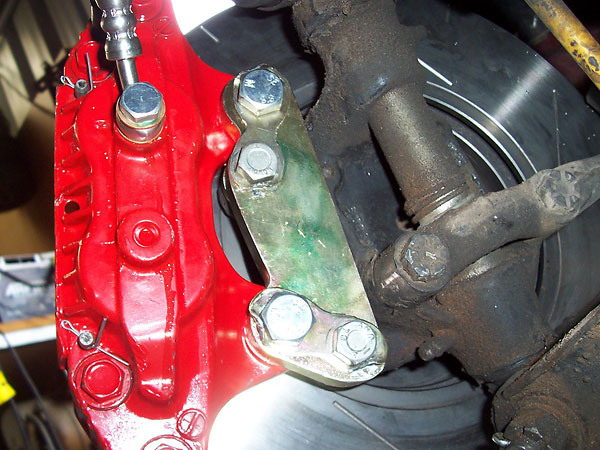

Since originally appearing in a "How It Was Done" article, I have uprated my�

front brakes again. The latest improvement includes fitment of 294mm OD x 22mm�

thick vented rotors from the BMW Mini Cooper S brake upgrade and Nissan GTR (R33)�

4-piston aluminum calipers and stainless steel braided brake lines. This all just�

fits inside 15 X 6.5 Volk Racing wheels. I'm using Hawk HP+ pads. The braking�

effect is now spectacular.�

�

All this comes with a price, I have had anti-tramp bars on the car for some�

time and now have uncovered the downside of a big torque engine and flimsy rear�

forward spring mounts. The torque force pushing the tramp bar forward have�

produced serious sheetmetal failure in the floor pan and in the front spring mount.�

MG obviously recognised weakness in this part of the body, and on the RV8�

they redesigned the floor area with a box section welded between the crossmember�

and the spring mount, plus two reinforcing plates either side from the spring�

pivot bolt and the torque control arm (tramp bar) carried forward and bolted�

through the new box section transferring and spreading the forces into the�

crossmember. I have fabricated a similar reinforcement and welded it into the�

floor.�

�

�

BMW Mini Cooper S vented brake rotors (294mm outside diameter by 22mm thick.)

�

�

Nissan GTR (R33) 4-piston aluminum calipers.

�

�

Stainless steel braided brake lines, and caliper adapter brackets.

�