�

�

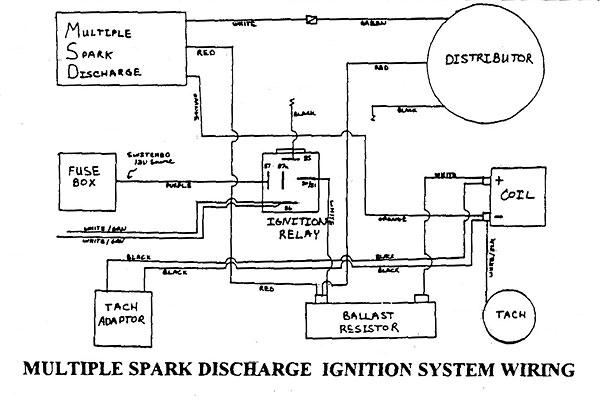

(this is the only illustration that accompanied the original article)

�

How It Was Done #4: Ken Williamson's 1980 MGB with Buick 215

��

This "How It Was Done" article was originally published in British V8 Newsletter, Volume 2 Issue 2.�

�

Owner: Ken Williamson

�

City: Bellefonte, Pennsylvania

�

Model: 1980 MGB Roadster

�

Engine: Buick 215�

�

�

The overall objective of this project was to substantially upgrade the MG's performance while�

maintaining the highest levels of safety, reliability, and driveability.�

�

�

ENGINE:�

1963 Buick 215 CID aluminum block and heads. Basic engine was left unmodified. Induction system�

is a Holley 390 cfm four barrel on an Offenhauser dual plane intake manifold. Camshaft is a�

Kenne-Bell model KB mark II. Exhaust manifolds are tubular headers unique to the MGB V-8 conversion.�

Ignition uses a Mallory Uni-Lite Module instead of the stock distributor. (See diagram.) Spark�

is enhanced by an Accel Super Coil and an MSD 5A unit mounted in the passenger footwell to avoid�

underhood heat. Lubrication system was improved with the installation of a high volume oil pump�

and oil cooler. Fuel is fed thru a Parker electric pump. Professionally estimated power is 220.�

�

�

DRIVETRAIN:�

With the help of Borg-Warner tech support, a clutch cover and disc were selected that would�

provide proper strength, pressure, and fit (and one that would remain available in the event�

that replacement was necessary.) Clutch is hydraulically actuated by a Datsun 280Z slave unit.�

Transmission is a Borg-Warner T-50 five speed from a 1977 Oldsmobile Cutlass. The transmission�

was disassembled and inspected prior to installation. Fifth gear is an overdrive ratio of 0.78:1.�

Driveshaft is a completely new unit custom fabricated by Driveline Service of Northern Virginia.�

Both front and rear yokes are heavy duty units that have industry standard replacement universal�

joints. Differential unit remains stock with 3.9:1 gears. Spider gear thrust washers were�

replaced when the unit was inspected and installed.�

�

�

WHEELS:�

TR6 wheels with Yokohama low profile 195/50 tires.�

�

�

BRAKES:�

Front Brakes were upgraded by the use of cross-drilled rotors. (See Newsletter Vol. 1 Issue 1 for�

cross-drilling template. -Ed.) and Feroda pads. The front and rear brake lines are stainless steel�

to reduce expansion under pressure.�

�

�

SUSPENSION:�

The car has been lowered in front and rear. Lowering was accomplished by fitting a '69 MGB�

crossmember and steering rack in place of the late model units. New front springs were fitted�

at that time and trunion bushings were replaced and reamed using the proper "Churchill" tool.�

MG V-8 lower control arm bushings replaced the standard ones. Replaced sway bar bushings in rear�

with spherical rod ends so they are solid. As a result, axle wrap is reduced and enhanced anti-roll�

capabilities are evident. A 3/4" diameter sway bar was substituted for the straight bar. The rear�

was lowered using Moss Motors lowering kit which consisted of two billet blocks of aluminum.�

�

�

COOLING SYSTEM:�

Radiator is an original MGB V-8 unit. System utilizes a header tank with coolant bleed hoses�

and a separate overflow tank to ensure an air free system. Three new electric fans are controlled�

by a Honda thermal switch.�

�

�

INTERIOR:�

Interior is black in color. Door panels and arm rest, under dash kick panels, and panels behind�

seats are finished in padded leather. Steering wheel is a black anodized aluminum and leather rimmed�

Moto-Lita. Mechanical water temp, oil temp, and oil pressure gauges are from Auto-Meter. The�

140mph speedometer is from a Jaguar. A yellow light on the speedometer lights when the cooling�

fans go on.�

�

�

PARTS UNIQUE TO THE CONVERSION:

�

• Motor mounts consist of two pieces per side. Special mounts on either side attach the engine�

to standard 1977-80 MGB mounts that bold directly to the frame in the original position. The special�

mounts, along with the exhaust headers and radiator are a special order from British Parts Direct.�

�

• Water pump is a short snout type available directly from D&D Fabrications. Other Buick�

pumps may be used if the pulley flange is pressed back and the snout shortened. Drive belt to water�

pump is a Goodyear P/N 13471.�

�

• Engine parts in general (excluding anything from the intake manifold up) are '63 Buick type.�

Try a local parts house initially as they can usually order things in a day or two. But if it becomes�

difficult to locate parts, refer to the sources list at the end of this article.�

�

• Clutch slave cylinder and hose are from a '78 Datsun 280Z. Beck Arnley P/N 030-05829 slave�

and 030-02678 hose.�

�

• Clutch release fork is a modified '68 Chevy Camaro, GM P/N 3892632. The release rod is a�

shortened VW Rabbit or Scirocco item. The need to replace these items is rare.�

�

• Transmission mount is a Borg-Warner P/N 31-2959.�

�

• Clutch components are Borg-Warner part numbers: pressure plate/cover 35-1525, disc 37-3303,�

release bearing '68 Chevy Camaro.�

�

• Oil cooler hoses are specially made and are available from any hydraulic hose distributor�

(refer to the Yellow Pages). Hose fittings may be reused if they are in acceptable condition as�

judged by the hose supplier. �

�

• Fan behind the radiator is from a 1978-80 Honda Accord. Thermal fan switch is from the same�

vehicle.�

�

• Exhaust from the collector back is best left to a custom exhaust person. First muffler is a�

standard "Turbo" type, and the rear muffler is a universal dual-tip a "ana" type. Specify under-the-axle�

routing as over-the-axle contacts the sway bar mounts.�

�

• Proper head gaskets can be ordered from Mountjoy's Autoshop. Specify the whick white asbestos�

Honest George type. Honest!�

�

• Alternator is a standard General Motors internal regulator type. Any amperage will probably�

work. In this car a 32 ampere was installed and works well.�

�

�

SUGGESTED MAINTENANCE SCHEDULE:

�

• A tune-up should be done every 12,000 miles or every third oil change. Change the spark plugs,�

front and rear fuel filters, and the oil and oil filter. Check the air filter. The timing should be set�

to 10-12 degrees advanced with the vacuum advance disconnected. If you are not a do-it-yourselfer,�

under no circumstances take this car to any "Precision Tune" or similar fast buck shop. However, even�

though this is a specialty car, a good MG repair shop should be able to handle a tune-up.�

�

• Oil and filter should be changed every 3,000 miles or every four months. Use 20/50W in the summer�

and 10/40W in the winter. Any good oil such as Valvoline or Castrol is fine. Oil filter is a Hastings�

P/N LF115 and should be changed every time you change the oil.�

�

• Air filter is a non-replaceable K&N unit. It should be washed every 15-20,000 miles under�

normal conditions.�

�

�

MAINTENANCE PARTS RECAP:

�

Water Pump Belt - Goodyear 13471

�

Spark Plugs - NGK BPR5ES

�

Radiator Cap - Stant Lev-R-Vent 16lb

�

Oil Filter - Hastings LF115

�

Thermostat - 195F in winter. 160-180F in summer.

�

Fuel filters - (front) Datsun type, (rear) universal type.�

�

�

PARTS SOURCES:

�

Lopar Performance

�

(discount speed parts supplier)

�

910 E. Indian School Rd., Phoenix AZ 85014, 602-264-5285�

�

D&D Fabrication

�

(anything for the engine. Dave LaGrew is an aluminum V-8 authority.)

�

3863 Vandyke St., Almont, MI 48003, 313-798-3911�

�

British Parts Direct

�

(V-8 conversion kits and individual conversion parts. Drilled brake rotors.)

�

4761 East China Hill, Diamond Springs, CA 95619, 916-626-0803�

�

Drive Line Service of Northern Virginia

�

(driveshaft related parts. Will ship UPS.)

�

4574 Eisenhower Ave., Alexandria, VA 22304, 703-370-1775.�

�