�

�

�

�

�

� Owner: Graham Creswick

� City: Chatham, Ontario, Canada

� � Model: 1976 MGB roadster

� Engine: Ford 302 V8

� Conversion performed by: Owner

��

�

�

�

�

�

Graham Creswick's 1976 MGB with Ford 302 V8

� as published in British V8 Newsletter, Volume XIV Issue 3, December 2006�� Owner: Graham Creswick

� City: Chatham, Ontario, Canada

� � Model: 1976 MGB roadster

� Engine: Ford 302 V8

� Conversion performed by: Owner

�

| Note: | �Vehicle was purchased in Texas as a "rust free" example - a complete teardown �

and ground up restoration followed and the first Oldsmobile 215 conversion was �

completed in 2 years. � Graham explained: I enjoyed the Olds-powered conversion for 2 years and at the � time it made most sense since the BOP/Rover parts/conversion support was in place. � After enjoying a spirited ride in Steve Carrick's "Barney" a few years ago, it � was inevitable that a move to the Ford 302 was in the cards. Tip: Choose the right � engine first time around and save time and money! | �

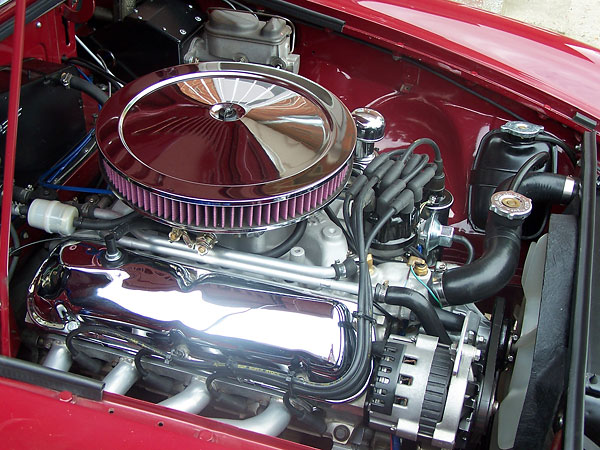

| Engine: | �Ford 302 H.O. roller lifter engine from a 1989 Mustang rebuilt with +0.030" Keith �

Black pistons (9.1:1 compression ratio), Ford Racing GT-40 aluminum heads, Fidenza �

aluminum flywheel, Ford Racing B351 roller rockers. Remote oil adapter and filter �

mounted in left wheel well. Engine mount isolators are from a 1962 Comet (289).�

With the BOP/Rover conversion, an engine steady bar was added to the front of the �

left cylinder head and, in my opinion is needed, since the MG engine isolators allow �

a lot of engine rocking. It has been retained with the Ford, but I don't believe it's �

as critical, as the Ford mounts are much more rigid. | �

| Intake: | �Edelbrock 2121 "Performer" intake, with 600cfm Edelbrock carb. This combination is �

low enough to fit under the standard MG hood. In fact, a 1/4" phenolic spacer was �

added under the carb to help reduce fuel percolation. Air cleaner is a 14" x 2" �

round with a 3/4" drop base. | �

| Cam: | �Ford Racing "B303". Valve lift is 0.480" and duration is 224 @ 0.050" for intake �

& exhaust. Rocker ratio is stock (1.6:1). | �

| Eng. Electrical: | �Base wiring is standard MG, but with wiring reconfigured for 8 cylinder conversion �

and distributor location. 1.5 ohm ballast resistor added in lieu of ballast wire �

internal to the original harness. Standard early "points type" Ford distributor �

converted to electronic with Crane XR-1 electronic module. Distributor drive gear �

changed to steel to be compatible with the steel roller camshaft. Original SU fuel �

pump was replaced with a Carter P-4070 with a Facet pump mounted in series and with �

an electrical selector switch in case of failure of one of the pumps. | �

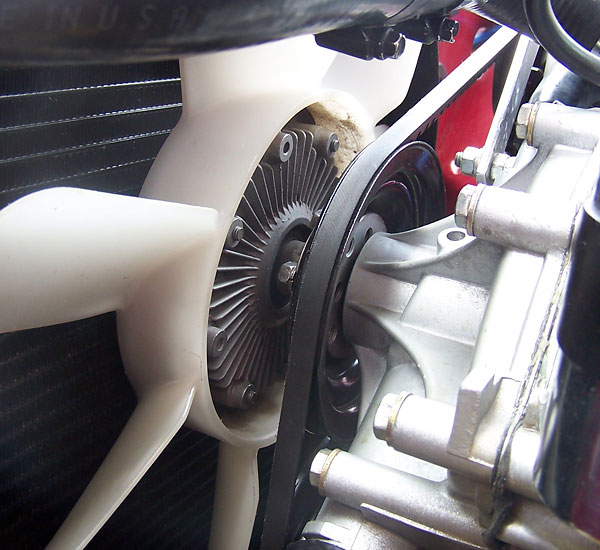

| Cooling: | �Ford "short" water pump M-8501-E351S. Early Ford 4 bolt crankshaft pulley and �

water pump pulley for V-belt drive. Crossflow radiator is made from early 1980's �

GM truck end tanks, with a louvered serpentine brass core. Core area is 296 sq.in. �

Overflow reservoir from late "B" added. Fan drive is a water pump mounted viscous �

unit from an early '80's Mitsubishi B50/Rampage with 15" plastic fan. Car has been �

in some hot day traffic and the cooling system typically stabilizes half way �

between "N" and "H". | �

| Exhaust: | �Headers by Coyote Engineering, with 1.5" primaries and 2.5" collector. They were �

ceramic coated before installation. Exhaust system is 2.25" diameter aluminized �

steel with dual Dynamax mufflers and with an "X" crossover pipe. The fuel tank was �

centered in the chassis to allow dual exhaust. | �

| Transmission: | �Borg Warner "World Class" T-5 (from a Ford Mustang) with the following gear ratios: �

3.35, 1.93, 1.29, 1.00, and 0.68:1. Shifter has been reworked from a standard Chevy �

S10 version, chrome plated and then assembled into a Ford T5 shifter housing. | �

| Clutch: | �Standard 1989 Mustang clutch & pressure plate. Original "pull" type cable actuation �

has been converted to a "push" slave cylinder from a 1980's Nissan. Clutch master �

cylinder is original. | �

| Driveshaft: | �2-1/2" diameter custom-length purchased from D&D Fabrications. | �

| Rear Axle: | �Ford 8.8, 3.27:1 Traction-Lok rear axle, shortened to same width as MGB disc �

wheel axle by Moser Engineering. 4 stud x 4-1/2" MGB lug pattern was retained. �

All suspension brackets cut from original axle and rewelded to new, plus �

sway bar brackets. | �

| Front Suspension: | �Lowering front coil springs added to otherwise stock MGB front suspension, fitted �

with red polyurethane bushings. Crossmember has been notched 1.5" to accommodate �

the lower Ford oil pan. Front swaybar has been uprated to 3/4" diameter. Note: to �

facilitate full wheel-cut Graham used a press to narrow the swaybar, reforming its�

center section with a gentle curve as shown above. | �

| Rear Suspension: | �Standard lowering MGB leaf springs and w/1" lowering blocks. Monroe 5877ST tube �

shock conversion. Late model 11/16" dia sway bar added and required sway bar �

attachment bracket fabrications welded to the body underside. | �

| Brakes: | �Standard MGB master cylinder/booster was replaced with �

an aluminum 1" bore non-servo master cylinder from an early 1980's Lincoln and �

plumbed with a Ford proportioning valve. Pedal ratio was increased from about �

4:1 to 6:1 by raising the pushrod attachment at the foot pedal. (Front) Standard �

MGB brakes with "Green stuff" pads. (Rear) Ford disc - standard 10.4" dia with �

1995 Mustang 8.8 axle. Emergency brake cams reworked to allow MGB e-brake cable �

actuation. | �

| Wheels: | �Panasport 15x7 with 22mm offset. Tires are 225/50ZR-15 Dunlop SP Sport 8000. | �

| Body/Interior: | �1976 rubber bumper car converted to chrome bumper. Original console removed in �

favour of the carpeted look of a '68 and added an early 1970's console to house �

the radio/CD and clock. Side marker lights removed and early '62-'69 rear �

taillights added. Original steel hood was replaced with early aluminum for 17lb �

weight saving and two rows of louvers added to help cooling. | �

| Electrical: | �Tachometer converted for 8 cylinder pulses. Speedo is 140mph unit from a '69 MGC �

and calibration is done by matching the plastic drive and driven gears within the�

T-5 transmission. | �

| Performance: | �Dyno'ed at the British V8 meet in 2005 (at Terre Haute IN) at 247hp at rear �

wheels. This was a hot day, so the engine mounted viscous fan was running. | �

| Sources: | �One cannot stress the importance of doing a lot of research/homework prior to �

starting a conversion. It was at the 2000 Cleveland show that I gathered most �

information, took photographs, asked questions, gathered supplier leads, took a �

test drive and formulated a plan. Supplement with Roger Williams excellent �

"How to...." books and the would-be converter is well armed for the job. Dan LaGrou �

of D&D Fabrications fortunately has his business about 2 hours from my home �

and was an excellent resource for conversion parts, information & experience �

on the BOP/Rover engine. | �

| Comments: | �One of the more serious problems encountered with the first conversion was one �

that has plagued a few of us: a leaky clutch hydraulic throw out bearing (HTOB). �

This is a very frustrating issue to have for a brand new (and expensive) part �

since the transmission has to removed to repair (in my case a cut "O" ring �

directly from the factory.) With the Ford conversion, an externally mounted clutch �

slave has been adapted and if a leak develops, it can be changed out in minutes. � A minor ongoing issue with the Ford conversion is to monitor how much the engine � mounts settle. There isn't a lot of clearance between some engine to chassis � components (specifically between front harmonic balancer and steering rack) and � I have had to add a couple of 1/16" shim plates to the front engine mounts to � regain clearance. � In some cases, converters have developed their own engine mounting locations, � accessory drives, unique component layouts, etc. and it is essential that, when � obtaining parts, to ensure that they will work in your specific case. For example, � if purchasing a set of headers that were designed for a specific engine position, � don't be surprised if they don't work for yours and will not allow full wheel � lock or the collector runs into some brake components - do your homework! � It is very unlikely that a first conversion attempt will be perfect. You'll find, � generally, that there will be ongoing improvements to the first design... that is � what makes the process enjoyable! � Now if I can only justify Ted Lathrop's front suspension to the missus! | �

| Completed: | �Original conversion was completed in late 2002 with a 215 cu.in Oldsmobile engine �

and T5 transmission. Powertrain was converted over to Ford components in the Winter �

of 2005. | �

| Miles driven: | �About 10,000 so far - most of them "enthusiastically"! | �

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

Graham Creswick (right) and fellow MGB V8 owner Peter Smith

�