�

�

Darren Jones's 1979 "MGB GT V8 Sebring" features a Rover 3.5

��

as published in British V8 Magazine, Volume XVI Issue 1, May 2008�

�

Owner: Darren Jones

�

�

City: Blackburn, Lancashire, UK

�

Model: 1979 MGB-GT

�

Engine: Rover 3.5L V8

�

Conversion by: Darren Jones and Robin Brown�

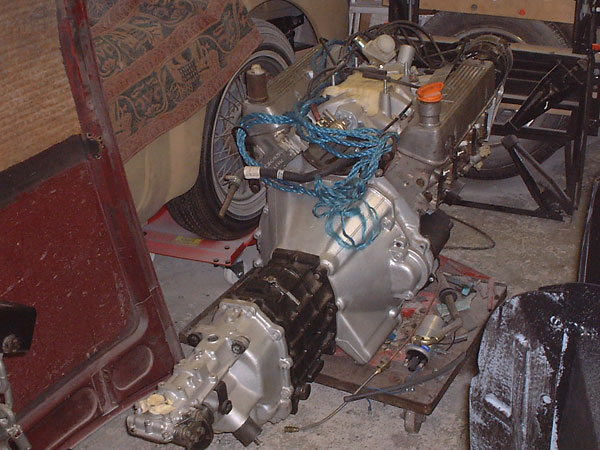

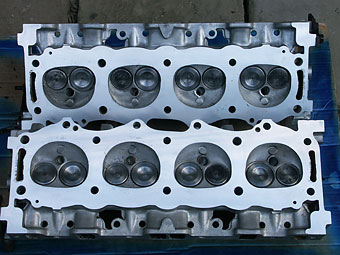

| Engine: | �Rover 3500cc V8. First unit was a second hand one putting out barely �

140bhp. This has been replaced with a reconditioned block and reground �

crank, with everything else new, giving about 200bhp. Piper 270/110 cam.�

Electronic ignition. | �

| Induction: | �Currently Weber 500, but soon to be replaced with 14CUX Hot Wire EFi. | �

| Cooling: | �new MGB V8 radiator, with twin electric fans as per the factory V8 model. | �

| Exhaust: | �big-bore system, with RV8-style through-the-wing headers. | �

| � |  � | �

| Transmission: | �Rover LT77 5-speed (from a Rover SD1). | �

| Rear Axle: | �Salisbury, with 3.07:1 gear ratio. | �

| Front Susp.: | �standard, except Spax adjustable shock absorbers and polyurethane bushings. | �

| Rear Susp.: | �standard, except Spax adjustable shock absorbers, plus the anti-sway �

bar has been cut and modified to function as anti-tramp bars. The main �

leafs of the leaf springs have been flipped upside down to provide a �

lowered stance. Polyurethane bushings. | �

| Brakes: | �EBC grooved and dimpled front rotors and Green Stuff pads. Stock rear brakes. | �

| Wheels/Tires: | �15x8 Minilites, 225/50-VR15 Toyo Proxes T1-R tires. | �

| Body: | �Sebring-style fiberglass fender flares and valances. (Instead of simply �

cutting out the original wheel arches from the steel quarterpanels, the �

steel arches were flared underneath the new fiberglass panels to retain �

structural integrity. Frenched license plate. MG "Trophy Blue" paint. | �

| Interior: | �1 GHz Mini-ITX computer with 7" touchscreen monitor mounted in the console�

in front of the shifter. The computer provides satellite navigation, MP3 �

audio, and DVD video. "Classic Vinyl" bucket seats with blue piping. �

Securon four-point safety harnesses. Mountney steering wheel. The rear seat �

has been removed, and the space converted to house the PC and stereo �

amplifier, with a parcel shelf above. (The car is now strictly a two-seater,�

"as it should have been.") Sony stereo with Pioneer speakers. | �

| Performance: | �not yet fully tested, but the car did reach 120mph at the Nurburgring during �

a holiday trip last August. | �

| Completed: | �summer 2005. (Driven approximately 5000 miles as of March 2008.) | �

| Comments: | �This is my interpretation of a British Hot Rod, she is everything I �

hoped for, a bespoke sports car which handles incredibly well. Due to �

its low ride, sticky tires and wide track, it gives a great grip and �

breaks away progressively in cornering or quickly if you want to, when �

having fun. Lapped the Nurburgring first time out in about 11 minutes, �

but I was so scared of going off so the time was fine.�

� Some MG enthusiasts are not too impressed with the non-standard � modifications, but I'm proud to say I salvaged a 4-pot rubber bumper GT � that was destined for the crusher and gave it new life. That's the best � kind of recycling!� � Next modifications will be the electronic fuel injection, primarily for � smoother running and fuel economy. I'd like to hook up the engine � management of the Rover 14CUX engine management system to my PC to � achieve real-time data access. If I can get it chipped, I'd like to be � able to switch fuel maps, depending upon circumstances. I've sourced an � MG RV8 bonnet, which will allow the Rover plenum to be used without � modification. � � Uprated brakes are also planned because the current ones fade during � track days.� � I use this car in all weather conditions. The chassis is waxoyled every � two years, and my local vehicle tester says it's in better condition than � other more recent cars. It has a couple of paint chips, and a war wound � from when I caught the exhaust on a ramp which pulled it out and damaged � the valance. That gives it character now.� � Two final things, if you look down on that front arch, its pure AC Cobra � - real 60's muscle car! If MG had had the wherewithal to make this model, � I feel sure it would have closed out the model on a high.� | �

How It Was Done:

��

I know exactly when I fell in love with the Sebring MG shape. I'd bought a 1972 MG BGT �

for my wife in 1995. It was a typical B: red, not in very good condition, but great fun. �

Inside the car I found a book about the MG marque with a picture of the John Chatham �

MGC GT Sebring. Instant desire... but I didn't think I'd ever own anything like it.�

�

In 2003, while waiting for a job opportunity in Bulgaria, I had some spare time and �

wanted to do something productive. A magazine article that suggested I could build an �

MG Sebring replica, but with Rover V8 power, on a £4000 budget really caught my �

imagination.�

�

I found a donor but decided very early, that I didn't want to create an absolute replica. �

I wanted something more contemporary and more personal. My car would be a bespoke sports �

car with all the latest features, including a suitable Rover V8 motor and the piece �

de resistance: a 7" touch screen PC to provide entertainment and navigation. (My trade �

always finds some way into my projects!) I also decided upon a later MG colour - �

"Trophy Blue" - which I felt would suit the car really well and bring it up to date.�

�

�

�

� In June 2003, after viewing several basket cases, I found a suitable donor car. I bought � a 1979 (rubber bumper) MGB GT which seemed generally sound apart from the sills. The sills � had been repaired previously, but not very well. With a little time on my hands and a � modicum of welding ability, I was prepared to try repairing the sills. I trailered the � car home behind my trusty 1973 Series III Land Rover. The car was a runner, recently out � of MOT, in dire need of some TLC and a good look at those sills.�

��

�

�

�

�

�

�

�

� Without a garage, my driveway was my workshop. Removal of the rubber bumpers made the � car look a little more lithe. Some prodding with a cold chisel showed the sills would � require a full rebuild. However, just as the project got underway, a temporary business � assignment threatened. As a consultant to the privatisation of a telecommunications company, � my due diligence work was critical to the deal - but the time in Sofia was going to impact � my schedule to complete the car before winter arrived. Without a garage, I needed some help. �

��

�

�

�

�

� I'd met a fellow enthusiast at the Woodvale car rally in August who'd built his own � MGB V8 Roadster. His partner in crime would be able to do the sills for less than the � cost of the normal MG restoration garages. Even with the saving, the cost immediately � blew my budget - and a precedent was set for the rest of the build. Oh well, easy come, � easy go! At least he confirmed that the rest of the body shell was as good as I hoped.�

��

�

�

�

�

�

�

�

�

�

�

�

When my GT returned with new sills, I felt I had a good canvas on which to create my �

version of a masterpiece. The next tasks were to remove the engine, gearbox, and the �

interior (plus some unusual items such as a Harry Moss digital tachometer and a Tracker �

trip computer) took two days. My plan was to renovate or replace as much as possible. �

However, before I dismantled and shipped the suspension and axle parts off for shot �

blasting, I planned to remove the underseal from underneath and then repaint with �

Hammerite black paint.�

�

I found that without the engine and gearbox removed, I could rotate the car up to �

about 30 degrees with my crane and then prop it up with strong axle stands, which gave �

me enough space to lie underneath. Armed with a heat gun and paint scraper, plus some �

cellulose thinners, I successfully removed all the underseal. However, the process �

aggravated a repetitive strain injury into tendonitis which means I'll have to have �

an operation at some point.�

�

�

�

�

�

�

�

�

� I sourced an engine and gearbox from one of the local Rover SD1 club members who also � loaned me an extra engine block to help with locating the exhaust manifold holes in � the wings and to offer the gearbox up for relieving the transmission tunnel, instead � of using the heavier complete engine.�

��

�

�

�

�

�

�

�

�

�

�

� By now it was October and the weather was closing in fast, there was no way I would � complete it before winter arrived so I started looking for a lockup garage to rent � nearby. After a couple of false starts, I found a unit in an old mill which suited � my requirements perfectly. It had been used as a garage previously, so it had a bench � and painted floor. Price agreed, the MGB along with an MGF and my Land Rover were � shuttled in away from the wet weather and I could proceed in relative comfort.�

��

�

�

�

�

�

�

�

�

�

�

�

�

�

�

I then started onto the body work. I'd heard that some other Sebring conversions had �

been achieved by cutting the inner and outer rear wheel arches and inserting a fillet �

of steel in between before gluing the glass arches on. I believe this weakens the �

structure, so I set about 'fan' slicing the rear arches and bending them up into �

the shape of the arch before seam welding each strip. This then gave me a good base �

upon which to glue the arches which I'd cut up to get rid of all the superfluous �

fibreglass. �

�

Over Christmas, progress was slow but at least the car was safe from the elements, �

I finished the arches, the metalwork extending the transmission tunnel, painted the �

interior floorpans and test-fitted the doors. It was important to get the fit right �

before offering the front wings to get the gaps right.�

�

Then my normal day job started again with a vengence. For 6 months the rebuild stalled �

and when my career moved me temporarily to Sofia Bulgaria there was a risk that the car �

would become one of those half-finished projects offered in the small ads. I was �

determined to not lose focus, having completed much of the hard work and with many of �

the parts purchased.�

�

Over these months, a good friend named Robin had become my project mentor. �

Robin had previously built a V8 Cobra replica, installed a Rover M16 engine in his �

own BGT, and was now working on his own MGA. He could see that all my work might come �

to nothing, and took pity on me. So, sadly, after delivering the car up to Robin's �

garage my involvement for the next 6 months was limited to following its progress �

through email and photographs. On occasional visits home I did get to witness some �

key milestones: first engine start in December 2004, selection of seats and belts, �

seeing the beautiful new Trophy Blue paint in April 2005, and finally selection of �

wheels and tyres in June.�

�

�

�

�

�

�

�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

These are the authentic British originals: genuine Minilite wheels!

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

Robin did a sterling job, finishing the bodywork and engine installation, arranging �

the paint job which really finishes the car, and putting his mark on it in the form �

of the 'frenched' rear number plate. That last feature seems a throwback to my �

interest in custom cars as a teenager, but it's also a design feature that looks like �

it should always have been there. �

�

I finished my assignment in summer 2005, which gave me the opportunity to complete �

the car with Robin, and I'm pleased to say, apart from a failed wheel bearing (one of �

the few things I didn't replace) it performed faultlessly on its first trip: a round �

trip of 1700 miles to and including a circuit of the Nurburgring. Two years and three �

times the original budget later, with Robin's help, I now have a bespoke, beautiful �

and quite unusual sports car.�

�

How It Turned Out:

�

�

�

�

�

�

�

� EBC high performance dimpled-and-slotted brake rotors, and "Green Stuff" brake pads.

�

�

� Cobra Classic seats with (optional) blue piping. These are often used by "classic Mini" owners.

�

� 1 GHz Mini-ITX computer with 7" touchscreen monitor (mounted in console) and wireless keyboard.

�

� The computer provides satellite navigation, MP3 audio, and DVD video.

�

�

�

� �

�

�

�

� Finally, the last pic is one of my favourites, my brother and I went to the 'Ring last � August. The car didn't miss a beat, and although we're both over 6' tall we managed to � sleep in it for a few hours in Belgium. We took aviation headsets and connected them to � an intercom and the PC (MP3 player, etc.), which made the motorway's more bearable. � We parked with the Triumph Club, and they were so welcoming. We'd love to get over this � year, but we have a new project to complete: a BMW E30 325 rally car. �

�