�

�

Charlie Baldwin's 1952 MG TD with Volvo B20 Engine

� �� Owner: Charlie Baldwin

� City: York, Pennsylvania

� Model: 1952 MG TD

� Engine: Volvo B20 four-cylinder

� Built by: owner �

�

How It Was Done

�| Engine: | �Volvo B20 2-liter engine, with B18 features to make it look more vintage.�

Volvo B20F 'D' camshaft.�

Volvo B20F cylinder head.�

(This is a lower compression but big valve variant that Volvo used with fuel injection.�

Fuel injector holes have been plugged.)�

Dual SU HS6 carburetors.�

Stock Volvo (Bosch) distributor.�

| �

| Cooling: | �original MG radiator, with inlet and outlet ports modified and relocated. | �

| Exhaust: | �late Volvo B20 exhaust manifold.�

Head pipe has 1.5" pipes transitioning into a 2" glass-pack,�

into a Volvo 1800E muffler (2" inlet and two 1.5" outlets) with two 1.5" tailpipes. | �

| Transmission: | �1965 Volvo 1800S M41 4-speed manual transmission, with�

Laycock D'Normanville D-type overdrive.�

Volvo stock hydraulic clutch slave fed by the clutch side of an MGA dual master cylinder,�

sleeved to 3/4" bore. (Originally, both bores were 7/8" diametder.)�

Shortened stock driveshaft. | �

| Rear Axle: | �1972 MGB tube type, with 3.91:1 ratio. (Stock for MG TD was 5.125:1.) | �

| Front Susp.: | �MGA 1600 front suspension (including hubs, coil springs, and shock absorbers.)�

MGB 3/4" anti-roll bar. | �

| Rear Susp.: | �stock MG TD leaf springs. | �

| Brakes: | �(master) MGA dual brake/clutch cylinder, with stock 7/8" bore on the brake side. � (front) MGA 1600 disc brakes. � (rear) 1972 MGB drum brakes. | �

| Wheels/Tires: | �15" Dunlop painted wire wheels with 165/15 tires. | �

| Instruments: | �stock, except the tachometer has been converted to electronic.�

The speedometer needs to be recalibrated to read correctly. | �

| Electrical: | �stock group-27 battery.�

Lucas C40 generator, mounted in Volvo bracket.�

Stock Lucas voltage regulator. | �

| Body: | �Halogen 7" sealed-beam headlights.�

LED taillights, brake lights, and turn signals. �

High-mount brake and turn signals using Lucas 1130 parking light bodies.�

Lucas back up light.�

| �

| Completed: | �Back on the road in June 2016.�

Overdrive rebuilt winter 2018 | �

| Comments: | �This MG was my first car, purchased in the spring of 1970.�

� Improved safety was really the central theme of this engine swap.� Power output is a safety issue because with stock engine my TD couldn't get out of� its own way. Now, it cruises well on the highway. With upgraded brakes, it also stops� more like a modern car. Even so, the driving experience has only� improved by getting rid of the major negatives of the car. It's great fun to drive and� has no issues with highway travel or covering large distances. I've installed lap belts� in the car, though with wood body framing it's hard to be confident whether staying in� the car in an accident would be better than getting thrown out.� � The Volvo B16, B18, or B20 is perfect for a T series MG because their SU carburetors� are on the same side of the engine as the stock XPAG and because the Volvo engines fit� with no cutting required. They look like they were put there by the MG factory.� � If using the Volvo 1800S remote shift setup, the gear shifter naturally falls exactly� at the stock position, so a regular MG carpet kit with shift boot can be used.� The Volvo hydraulic clutch is much better than the stock MG mechanical rod or cable clutch.� � The stock TD engine output from the 1250cc XPAG engine is 54 hp. The Volvo engines� have different outputs depending on what model they came from. B16 was rated at� approximately 85hp, B18 in 1800S form was rated 108hp, and B20 in 1800S form was rated� 115hp. The fuel injected, high compression version of the B20 (a.k.a. "B20E") were rated� 130hp. Low compression B20F's were rated 125hp. Using the B20F head with SU carbs,� fuel-injection camshaft, and mild port polishing probably brings mine in around 120hp� using the original factory method of stating horsepower output.� � Volvo B16 engines are from the mid to late 1950s, B18 engines are from the early 1960s,� and B20 engines are from the late 1960s through 1975. The B16 engines have three main bearings.� B18's and B20's are five main bearing engines, and are just different capacities of� basically the same engine. Fuel injection became standard in 1973, but was available� in 1970 in the 1800E, and 1971 in the 142E. (Some foreign car markets may have had fuel� injected 122S models.) The Volvo engines are named for their capacity in CCs.� � Interested in a Volvo engine swap of your own? Check out:� Volvo Engined MGs!� New members are welcome. � � | �

Engine Installation

��

�

Volvo B20 2-liter engine, with B18 features to make it look more vintage.

�

�

Dual SU HS6 carburetors.

�

�

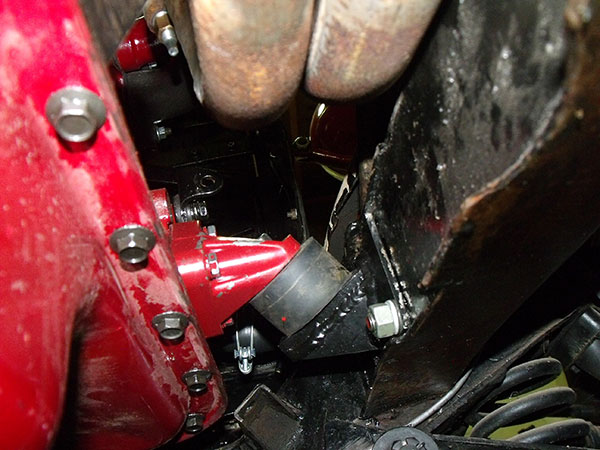

Engine mount, viewed from above.

�

�

Engine mount, viewed from below.

�

�

Custom fabricated engine mount, welded up.

�

Cooling System Modifications

��

The next topic that I would like to bring up is the cooling system. With the Volvo engine being�

quite a bit larger in capacity than the XPAG, one may think that the T series radiator may not�

have enough capacity to maintain the correct water temperature. My experience has been that�

there is no problem in that respect. �

�

You may want to modify the radiator a bit, though, to make it easier to connect it to the Volvo�

engine. I have a TD, so I can only discuss what can be done with that model. The TD has a�

non-pressurized cooling system as does the TC also. The TF, however, has a pressurized system.�

With a TD, it does not seem to matter that the Volvo engines as used in the vintage Volvos had�

pressurized systems and the TD doesn't. �

�

�

�

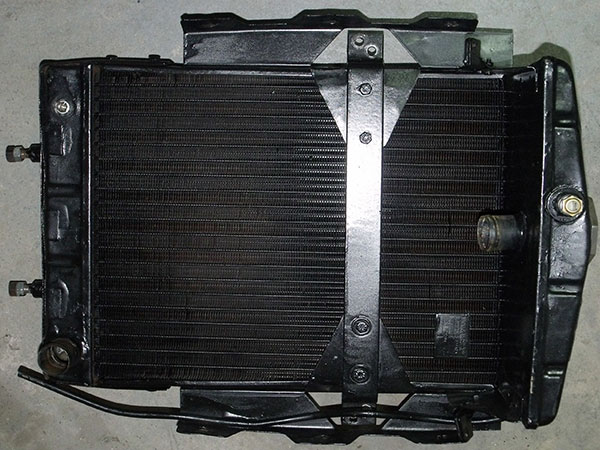

Stock MG TD radiator.

�

�

The upper hose on a stock TD is 2 1/8" diameter, however, the Volvo thermostat housing where the�

upper hose connects is 1" for earlier engines and 1.25" for later ones. It may be the smaller for�

B18s and the larger for B20s. Either one will fit on either engine. I have a B20 with the larger�

housing. I took the radiator to a radiator shop and had him remove the 2 1/8" connection and solder�

in a 1.25" connection. See the pictures of the stock 2 1/8" connection and the modified 1.25"�

connection. Then I made a full scale sketch from the side of the relationship between the thermostat�

housing and the connection at the radiator and took it to NAPA where we went through a bunch of hoses�

and picked one out that would work. This may vary depending on how you have positioned your engine.�

�

�

�

Modestly modified MG TD radiator.

�

�

I also had the bottom connection modified by the radiator shop. A 122S or 1800E bottom radiator�

hose worked here for me. Either hose is 1.25" at the radiator end. It seems like the 122S hose�

will work best on my car.�

�

�

�

Lower radiator hose connection.

�

�

The correct bottom hose is shaped so it has more room to avoid the generator pulley from cutting it.�

See all of the pictures on this. The difference between the 122S and 1800E bottom hoses is slight.�

The 1800E hose is around 1/2" longer at the radiator end. I ended up taking my radiator back to the�

shop to have him move the connection over to the right hand side as far as it will go. The idea is�

to get it into the bottom corner. It would also probably help to have it angled down a bit on my�

car since the hose needs to be angled up. Some may have to cut off some of the hose at the engine�

end, but I did not.�

�

My opinion is that it is best to modify the radiator at the bottom in this way so that the fan�

blades do not have to be cut shorter. Since the Volvo engine sits lower in the car than the MG�

engine the fan will hit the stock bottom connection and also the drain petcock. On mine I elected�

to just plug the drain hole in the radiator and to empty it loosen the bottom hose with a tub under�

the cross member to catch the coolant. �

�

Transmission Installation

��

�

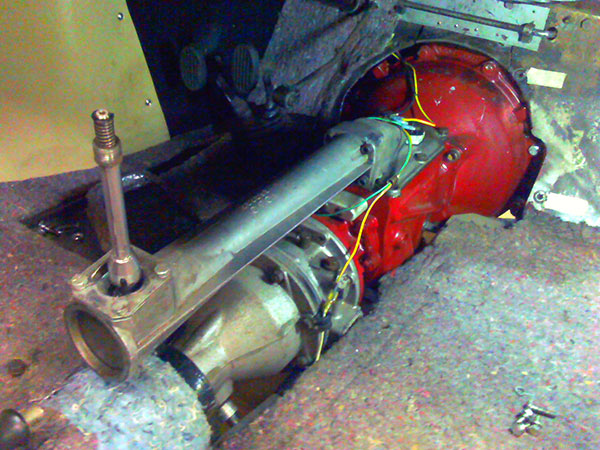

Volvo bellhousing.

�

�

Volvo M41 transmission with Laycock D-type overdrive.

�

�

Internally a Volvo M41 gearbox is similar to a Volvo M40 gearbox. Difference? The M41's mainshaft

�

extends through the adapter between gearbox and overdrive unit, and through the overdrive unit.

�

�

Propeller shaft installed.

�

�

Transmission insulation and rubber excluder.

�

Clutch Activation

��

Here is one way to handle clutch activation when using the Volvo M40 or M41 transmission.�

The M40 is the 4 speed and the M41 is the 4 speed plus overdrive. The earlier ones are�

hydraulic and the later ones are cable operated. To me, the hydraulic activation is the�

best way to go. Cable operation would require structure to pull from and a cable of the�

correct length.�

�

My opinion on the best way to activate the hydraulic clutch is to use the MGA/Bugeye�

Sprite combination brake/clutch master cylinder at the pedal end. One good thing about�

it is that the bolt spacing is the same as the stock TD/TF brake master cylinder and the�

bore, at 7/8", is also the same.�

�

�

�

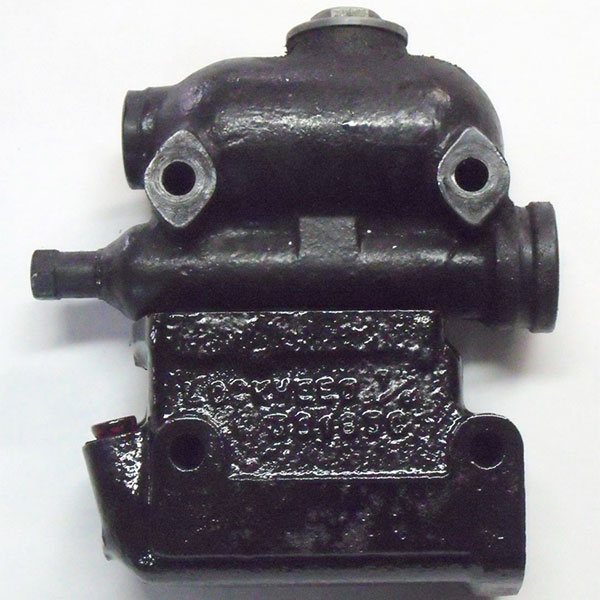

Top: MG TD/TF master cylinder. Bottom: MGA master cylinder.

�

�

Another advantage is that the brake/clutch master cylinder will mount at exactly the�

same place and take up approximately the same amount of room as the original brake�

master cylinder, thus requiring no extra structure to mount a separate clutch master�

cylinder. The MGA braking system is very similar to the TD and TF, so there is no question�

that the MGA master cylinder will handle the job.�

�

This setup will require the MGA master cylinder to be spaced away from where it mounts�

to the frame of the car in order for the push rods for the brake and clutch to line up�

with the pedals. �

�

�

�

The master cylinders, laying on the side you'd mount to the frame (on left-hand-drive car).

�

�

It can easily be seen that the center of the MGA bore is much closer to the bottom�

than the center of the TD/F bore. The amount that the MGA master cylinder needs to�

be spaced off the frame is 7/16" for the push rods to line up with the pedals. �

�

On my car, I just retained the stock TD push rod for the brake side. Remember that�

on the TD/F the shaft design for the pedals has the brake closest to the frame and�

the clutch closest to the center of the car, which is backwards from what you would think.�

So in the above picture, for a left hand drive car, the brake bore in the MGA master�

cylinder is at the bottom, with the top bore being for the clutch.�

�

The MGA master cylinder has both bores at 7/8"; however, the Volvo clutch system uses�

a 3/4" bore. So the clutch side of the master cylinder needs to be 3/4", which can be�

sleeved to that dimension. I sent mine away to be sleeved by Sierra Specialty in�

California. They are out of business, but I understand that Apple Hydraulics can do�

this work. They do brass sleeves which is what I prefer over stainless steel.�

You can probably buy the master cylinder and everything from Apple. �

You will also need the 3/4" piston and spring for this bore. �

�

Because the master cylinder has been spaced away from the frame, longer bolts will be�

required. On my car the thread form for the bolts is 3/8"-20 BSF. I bought a die online,�

bought some longer bolts at Lowe's, cut the threaded end off, and cut the BSF threads�

on them.�

�

If you need a new master cylinder, they are being reproduced in 7/8" bore (Moss 180-670).�

�

Part of the system is the slave cylinder mounted on the bell housing. I used the�

Volvo cylinder for this since it is made to mount on the bellhousing and to push the�

clutch arm. Along with that the correct push rod, return spring, return spring anchor,�

and the right size bolts will be required. Then you will need to make the hard brake�

and clutch lines to go from the master cylinder to the brake system union and the�

clutch line forward to near to the slave cylinder. A flexible hose will be required�

to connect to the slave cylinder. I used an MGA brake hose (Moss 180-831 with 324-730,�

311-420, and 324-180). For the hard lines I use cunifer tubing from Fedhill Brake.�

It is easier to form the flares than regular steel tubing. Fedhill can also supply�

the end fittings that you will need. You will need to flare the ends of the tubing.�

The MGA master cylinder should have bubble flares, not double flares. The line from�

the master cylinder on the brake side will go to the same union that it went to before.�

It will need an MGA fitting (3/8"-24) on the master cylinder end and a TD fitting�

(3/8"-20 BSF)on the other end. The clutch side will need the MGA fitting with bubble�

flare on the master cylinder end and should run forward against the frame behind the�

pedal box to where you connect it to the hose that attaches to the slave cylinder.�

�

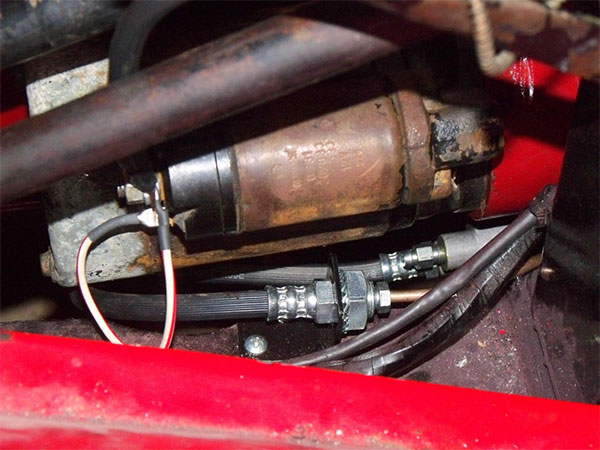

�

�

Since the hose is an MGA one, use an MGA fitting and a bubble flare at that end also.

�

�

Next, a push rod will need to be fabricated for the clutch side. Mine needed to�

be around 5 1/2" long. You will need a fork or clevis like Moss 180-315, a clevis pin�

– 325-150 or 180-325, and a return spring – 180-335. A hole for the clevis pin needs�

to be drilled at the same height as the one for the brake side. The existing hole where�

the clutch rod connects can be used for the return spring. You will need to make a way�

to attach it to the front side of the pedal box. �

�

�

�

Here is what it looks like at the pedal box...

�

�

Note how the cap at the top of the master cylinder can be accessed through the�

same hole in the floorboard as the original TD master cylinder.�

�

Front Suspension

��

�

MGA 1600 front suspension (including hubs, coil springs, and shock absorbers.)

�

�

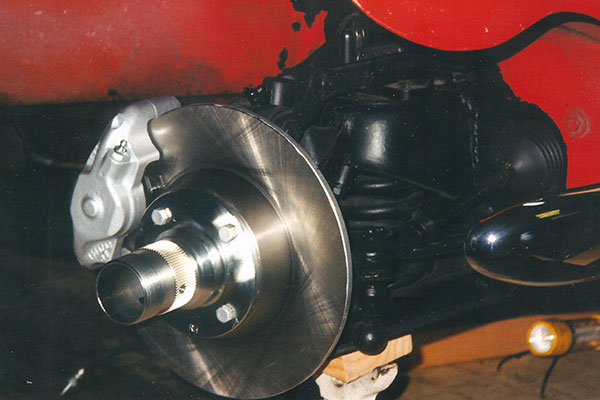

MGA 1600 disc brakes.

�

�

MGA brake rotor.

�

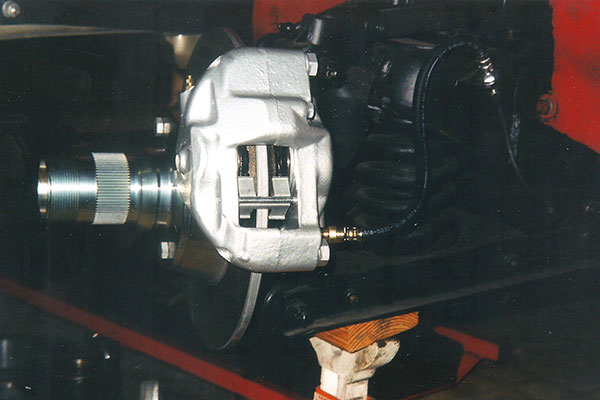

�

MGA brake caliper.

�

�

MGA dual brake/clutch cylinder, with 7/8" bore.

�

Exterior

��

�

Charlie autocrossing his MG TD in Carlisle, Pennsylvania. These action photos were taken before

�

the engine swap, but after installation of MGA front disc brakes and a 5/8" anti-roll bar.

�

�

MG TD's came without any anti-roll bar, so you can imagine how much a stock TD would lean.

�

After this photo was taken, Charlie fitted an MGB pattern 3/4" anti-roll bar.

�

�

At an informal car show in Dover, Pennsylvania.

�

�

At Lancaster County MG Club's 17th annual "British Invade Gettysburg" car show.

�

�

High-mounted LED brake lights.

�

�

Complete rear lighting package.

�

�

At the Carlisle Import & Performance Nationals Show, 2017.

�

�

Copyright 2019. All rights reserved.�

Use by written permission only.�

(Do not print, copy to your hard drive, or post these online without permission.)

�