�

�

Positive Crankcase Ventilation

� as published in BritishV8 Magazine, Volume XVII Issue 1, July 2009�� by: Jim Blackwood�

�

�

The positive crankcase ventilation (PCV) system, and older "road tube" systems �

that preceded PCV, are for venting combustion products from the crankcase in �

the most unobtrusive manner consistent with the times. To understand these �

systems, it's necessary to realize that "blowby" inevitably exists in any internal �

combustion engine. For example, whenever a piston engine runs, there will be �

some passage of gasses and vapors past the piston rings, and into the crankcase. �

This will occur despite the finest components, the most precise machining and �

the most careful assembly. Blowby includes volatile and potentially explosive �

fuel fumes, as well as contaminants that degrade oil. (Solids, such as ash, are �

carried with the gasses.) Modern sealing methods are simply incapable of preventing�

blowby. It may not be much, but blowby is inevitable and it has to be dealt with. �

�

Originally engines were built with an open crankcase and no special provision was �

needed. The closed crankcase came about because of a desire to re-use the �

lubricating oil which had previously been allowed to simply fall to the ground. �

As this evolved, manufacturers began sealing the crankshaft from the outside �

environment to both contain the oil and exclude contaminants. Engine speeds were �

increasing as well and pressurized lubricating systems were needed to deal with �

the increased bearing loads, meaning there was a great deal more oil being flung �

about. At this point it became clear that venting of some sort was required to �

avoid pressurizing the crankcase to a level which seals and gaskets weren't capable �

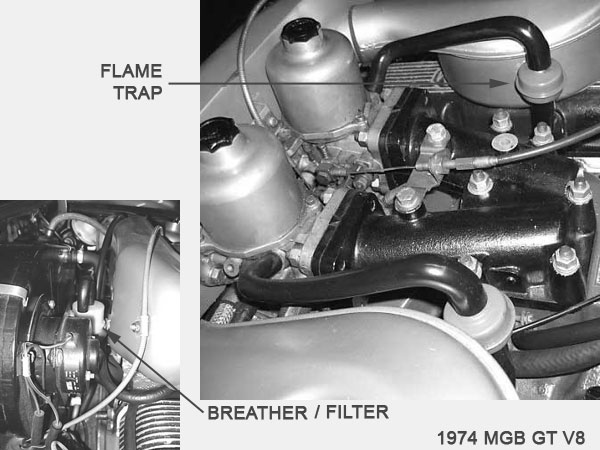

of withstanding, and various types of vents were developed. Due to the possibility �

of crankcase explosions almost all of these venting methods also included a flame �

arrestor of some type, but they were in general as simple and direct as engine �

manufacturers could make them. �

�

The problem with this type of vent of course is that it was nearly impossible to �

remove all of the oil from the vapors that exited the vent, and as a result an �

oily residue was deposited nearby. Also under heavy acceleration when cylinder �

pressures are highest and the most blowby is produced, enough fumes exited the �

vents to create objectionable fumes in the passenger compartment of the vehicle. �

These problems led to development of the road tube which was very effective, �

resulted in much cleaner engine compartments and cleaner air for the driver and �

passengers. It diverted the objectionable fumes and oil spray down under the car �

and was a significant advance. The downside was that the oil vapors were now �

deposited on the road surface, leaving a wide, dark oily swath between the two �

tire tracks of public roads.�

�

�

�

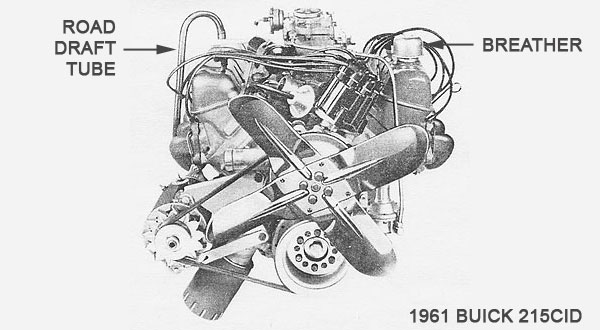

It was soon discovered that by cutting the end of the road draft tube at an angle �

and extending it into the airstream below the car an actual flow of fresh air could �

be created through the engine by providing an inlet breather, often in the form of �

an oil filler cap with a coarse mesh filter material, which acted as a flame arrestor �

and kept bugs out of the crankcase. A similar mesh in the road tube (sometimes placed �

inside the engine) served the same purpose on the other end. This new development �

was highly touted as an advancement which increased both engine life and oil change �

intervals by removing combustion byproducts quickly before they could combine with �

the crankcase oil and form acids, sludge, and other harmful and non-lubricating �

contaminants. �

�

This insight ultimately led to the development of the modern PCV system as we know �

it today. Various schemes were tried in order to find new ways of evacuating gasses �

from the crankcase, but what most had in common was that they relied on some means �

of suction to do the job. This generally meant the use of manifold vacuum as the most �

practical method. For us this means two things: firstly that most PCV systems are �

pretty consistent, and secondly that other alternative methods are possible.�

�

�

�

The usual PCV systems come in two basic flavors, and I'll distinguish them here by �

referring to them as American and British respectively, due to the prevalence of �

their use by manufacturers in each country, and in particular in distinguishing �

LBC's from Detroit iron. �

�

In the British system, which is the more straightforward of the two, manifold vacuum �

is plumbed directly to the crankcase using a 0.5" or 0.75" diameter line. An orifice �

of typically 0.030" or less is provided on a line feeding fresh air into the crankcase. �

Sometimes this line draws vapors from a vapor recovery canister as well, thereby purging �

the canister and feeding those vapors indirectly into the engine intake, and sometimes �

this orifice is contained in an oil filler cap, but for the purposes of PCV it functions �

the same either way. It does however have the potential to either enrich or lean the �

idle mixture to a limited degree. The manifold vacuum purges the crankcase of blowby �

fumes. By placing the crankcase under vacuum, a metered quantity of fresh air is �

drawn into the crankcase through the orifice... at least at idle and part throttle. �

As the throttle opens and engine load increase, blowby also increases proportionally �

until at some point the crankcase transitions from vacuum to positive pressure. This �

may not occur with a new engine in good condition using a larger vacuum line, but �

it certainly will with an engine having significant mileage. When the crankcase is at �

positive pressure, nothing changes on the vacuum side other than the volume of gasses �

going into the intake, but on the orifice side the flow reverses. This is usually not �

particularly significant due to the small size, but can contaminate the carbon in the �

vacuum canister over the course of time.�

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

American systems use a large diameter vent line to the atmosphere, usually running �

from a valve cover to a location in the air filter housing, and a smaller diameter �

line to the intake manifold, usually 0.3125" to 0.375" in diameter. This system �

restricts the amount of combustible air which enters the engine with a PCV valve �

rather than an orifice, and it is placed in this intake line. The PCV valve is pretty �

unique in that it allows full flow at low pressure differentials across the valve �

and a metered restriction above that level. It also shuts off flow in the reverse �

direction, thereby eliminating the need for a flame trap. This is done by using a �

shuttle inside the valve which I'll return to shortly, as this is the most misunderstood �

part of the system. �

�

The crankcase is never under vacuum but can become slightly pressurized. The large �

diameter vent line allows fresh air into the crankcase and also allows excess blowby �

to vent into the air cleaner housing through a flame arrestor where they are ingested �

by the engine, whenever engine loads and throttle openings are great. Under part �

throttle the PCV valve is open due to the lower vacuum applied across it and the �

lower level of blowby so most if not all of the blowby is sucked into the intake, �

drawing fresh air into the engine in the process and also tending to lean out the �

intake mixture during cruise. During idle there is enough vacuum to shuttle the �

PCV valve to the metered position and there is usually very little blowby so most �

of that is ingested along with a small amount of fresh air which is accounted for �

by adjustment of the idle mixture screws. This is one reason the idle mixture has �

to be adjusted as the rings wear. Under heavy throttle, although the level of �

vacuum drops to near zero, should the level of blowby become great enough the �

shuttle will shut down the flow to the metered level, diverting most of the blowby �

to the air cleaner and ingesting only a metered amount of blowby through the PCV �

valve. �

�

The effect of routing these gasses through the air cleaner is to enrich �

the intake mixture proportionally because the carb doesn't know the difference �

between fresh air and recycled combustion by-products. So it is interesting that �

the PCV system helps to give us a lean cruise and a rich WOT, but there is little �

or no correlation between PCV, carburetor, and volume of blowby other than the �

initial calibrations of the carb and PCV valve and no mechanism to account for �

engine wear other than the shuttle valve and idle mixture screws. The interesting �

thing about this is that the same PCV system is still in use with very little �

modification on our newer fuel injected engines, although they do have a feedback �

mechanism in the form of an oxygen sensor.�

�

These systems work quite well normally, but things tend to get interesting �

once performance modifications are made. Often the PCV systems are unintentionally �

modified to the point that they can no longer function properly, and this is �

particularly common with aftermarket intakes, air filters, valve covers, forced �

induction and the like. It is still possible on almost any performance engine �

to design and tune for a PCV system that works properly and this is especially �

important in a street driven car. For all out performance it is less of a �

consideration and in fact the blowby fumes do dilute the intake charge somewhat, �

so in these cases a simple crankcase vent is often used, harking back to the early �

days, with all their attendant inconveniences. Often modifications are made to the �

system unintentionally, in the quest for more performance and a better appearance, �

and this can result in problems. One of the most bothersome is pressurization of �

the crankcase, with symptoms of excess oil sprayed about the engine compartment �

in various places as it is forced past gaskets and seals. Another is the chance �

of a crankcase explosion should the need for a flame trap be overlooked. Then of �

course, any improperly functioning system will have a need for more frequent oil �

changes, as the combustion byproducts contaminate the oil more rapidly.�

�

For your street driven car there are answers. Sometimes the British system is �

more appropriate, and sometimes American, but it's best to keep in mind how each �

one operates and not try to mix the two. When fitting an open element air cleaner �

onto a typical American 4-barrel carbureted V8, for instance, it's quite easy to �

install the vent line to the base of the air cleaner inside the element, thereby �

keeping the system intact. Things aren't quite so neat and clean when fitting a �

similar air cleaner on a Rover V8, because Rover engines were originally set up �

with an orifice-type system. Some of these are easily changed over and some are �

not, depending on the fittings on the rocker covers. Bear in mind that the large �

vent line of 0.625" or possibly 0.75" in some cases cannot be replaced with a �

0.375" hose, or even two of them. Flow increases by the square of the diameter, �

meaning that a 2" pipe flows four times as much as a 1" pipe. So you would need �

four 0.375" lines to match one 0.75" line. If your valvecovers do not have the �

proper fittings and you are not willing to add larger ones to them then you may �

need a larger line to the crankcase in an alternate location. Early SBC's had a �

vent line that went through the block web behind the intake manifold. A large �

diameter tube rising from the pan may be another option. You might use the �

mechanical fuel pump mounting boss. Or you may be able to use the orifice system, �

bearing in mind that using smaller lines will cause it to operate under pressure �

more than it might otherwise. This may require recalibration of your carburetor �

due to the differences mentioned above, or it may be possible to find a suitable �

carburetor calibrated for the orifice system, since some British cars were �

available with a four barrel carburetor. There are other cases where an orifice �

system is a good choice, such as any induction system where the throttle body is �

at the inlet of the system. This might be the case with an IR setup or where an �

engine is supercharged. In these situations there is no practical way to locate �

the vent tube, and therefore no way to ingest the excess blowby fumes. The solution �

is to port the crankcase to manifold vacuum (or inlet vacuum in the case of a �

blower) and use the orifice to restrict flow into the crankcase and subsequent �

leaning of the intake mixture. It is worth noting here that often EFI systems �

take control of the PCV system, such as by including a purge valve for the �

emissions canister, allowing options such as pulling fresh air in at idle to give �

more precise control of the mixture. Some of these systems may be able to divert �

PCV intake on WOT for maximum power output. WARNING: All lines from crankcase to �

intake system must have some form of flame arrester! To overlook this is to invite �

a crankcase explosion, which in the best possible scenario will have you replacing �

your lifter valley pan.�

�

Finally, we have the alternative systems, the most familiar being the collector �

scavenger tube. These are really not suitable for a street driven application �

because of two things: mufflers, and the fact that they do not work well at idle. �

For racing it's a good idea, but once you add the restriction of a muffler you �

have created backpressure which will reverse the flow in the scavenger tube and �

make the system ineffective. Another option is an external scavenger pump. These �

tend to be a more complicated solution, but are another possibility that may �

have merit in special situations. Theoretically it would be possible to evacuate �

the crankcase using positive pressure and this would tend to lead to seal problems, �

but if those woes were overcome one might even find a way to route forced induction �

through the crankcase on its way to the cylinder, provided an adequate air/oil �

separator were designed. Two stroke engines inherently use this principle, simply �

burning the oil as they go.�

�

So that's the basic lowdown. No doubt there are details that I've left out but �

it's enough to give the average person the picture. Hopefully it's enough to help �

sort through the tangled mess and maze of confusion that typically surrounds �

these systems.�

� Disclaimer: This page was researched and written by Jim Blackwood. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�