�

�

�

�

�

�

� by: Dan LaGrou and Kurt Schley�

� The use of a GM style T-5 5-speed transmission for MG V8 conversion use has become very � popular over the last several years. The advantages of the T-5 over the more traditional � Rover 5-speed box are lighter weight (70 vs. 90 lbs), no internal oil pump to go bad, and � that the stock 3.9 rear end need not be changed. The GM style T-5 bolts directly onto � either an OEM 215 or an aftermarket bellhousing. These bellhousings, in turn, will mate � with any of the Rover V8 engine blocks without modification. However, there is one caveat: � at some point in the last twenty years, the Rover crankshaft grew an extra 3/8" at the rear. � This longer length causes interference with the T-5 input shaft. The solutions to this � problem are not complicated at all. The first option is to fabricate a 3/8" thick aluminum � spacer between the bellhousing and the block, thus moving the transmission rearward. The � second option is to remove 0.300" from the rear of the crankshaft. (See illustration "A".) � This modification takes only 15 minutes or so, providing you have access to a lathe. The � following is the technique developed by Dan LaGrou of D&D Fabrications.�

�

�

�

�

�

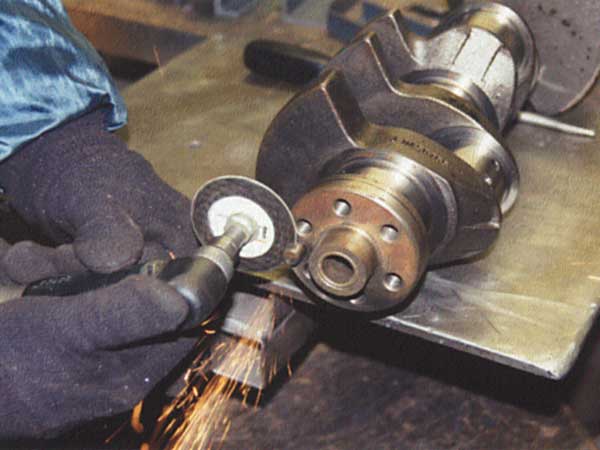

Photo 1: Cutting dowel pin from Rover 4.0 crankshaft �

Modifying the Rover Crankshaft for T-5 Transmission Use

� as published in British V8 Newsletter, Volume XIII Issue 3, September 2005�� by: Dan LaGrou and Kurt Schley�

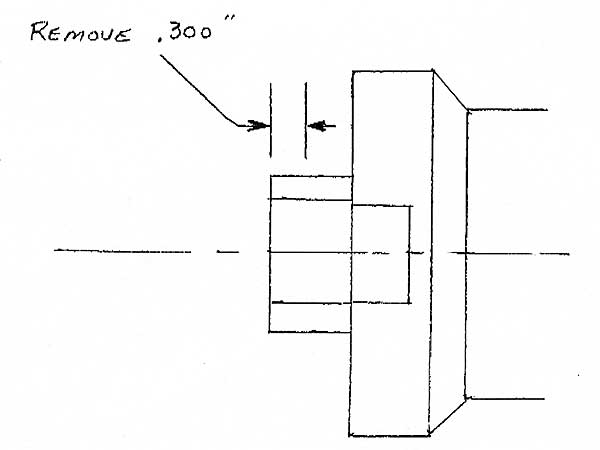

� The use of a GM style T-5 5-speed transmission for MG V8 conversion use has become very � popular over the last several years. The advantages of the T-5 over the more traditional � Rover 5-speed box are lighter weight (70 vs. 90 lbs), no internal oil pump to go bad, and � that the stock 3.9 rear end need not be changed. The GM style T-5 bolts directly onto � either an OEM 215 or an aftermarket bellhousing. These bellhousings, in turn, will mate � with any of the Rover V8 engine blocks without modification. However, there is one caveat: � at some point in the last twenty years, the Rover crankshaft grew an extra 3/8" at the rear. � This longer length causes interference with the T-5 input shaft. The solutions to this � problem are not complicated at all. The first option is to fabricate a 3/8" thick aluminum � spacer between the bellhousing and the block, thus moving the transmission rearward. The � second option is to remove 0.300" from the rear of the crankshaft. (See illustration "A".) � This modification takes only 15 minutes or so, providing you have access to a lathe. The � following is the technique developed by Dan LaGrou of D&D Fabrications.�

�

�

1) The Rover crankshafts have a single dowel protruding from the rear flange. This dowel �

is cut off flush with the flange face. (See photos 1 and 2.) Do not pull the complete dowel �

from the flange as this will noticeably affect crank balance.�

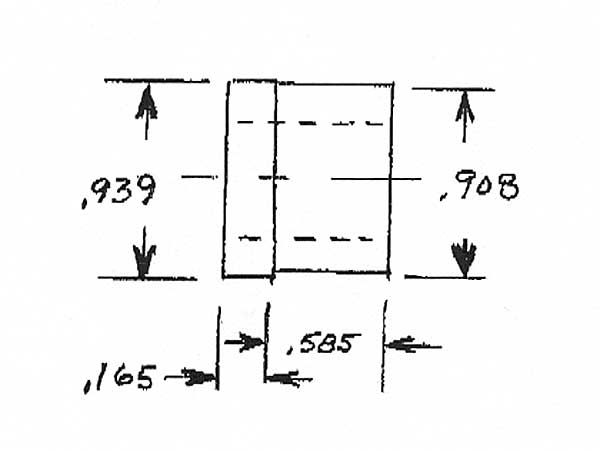

� 2) Dan has fabricated a simple aluminum insert (see illustration "B") to support and index � the rear of the Rover crankshaft in the lathe tailstock. The adapter inserts approximately � 1-1/8" into the bore for the pilot bushing, with a snug fit (once the original bushing has � been removed). The end of the adapter is countersunk to accept the lathe tailstock center. � (See photo 3.) A new bushing can be made, with similar dimensions, out of "Oilite" bronze.�

��

�

�

�

�

� 2) Dan has fabricated a simple aluminum insert (see illustration "B") to support and index � the rear of the Rover crankshaft in the lathe tailstock. The adapter inserts approximately � 1-1/8" into the bore for the pilot bushing, with a snug fit (once the original bushing has � been removed). The end of the adapter is countersunk to accept the lathe tailstock center. � (See photo 3.) A new bushing can be made, with similar dimensions, out of "Oilite" bronze.�

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

�

�

3) A parting tool is then employed to remove approximately 0.300 - 0.320" of the crankshaft �

end. (See photo 4.)�

� 4) After the crank is shortened, all of the cut edges should be chamfered with a file to � remove burrs.�

�

Photo 2: Trimmed dowel pin

�

� Illustration A (what we are ultimately trying to accomplish): Measure depth of bushing hole � to where the inside diameter steps in, as well as depth to bottom of hole, and make aluminum � lathe insert deep enough that it nearly reaches the bottom, for maximum support during parting � operations. Use the diameter measurements in Illustration B, and adjust the lengths to fit � your crank.

�

�

�

� 4) After the crank is shortened, all of the cut edges should be chamfered with a file to � remove burrs.�

�

Photo 2: Trimmed dowel pin

�

� Illustration A (what we are ultimately trying to accomplish): Measure depth of bushing hole � to where the inside diameter steps in, as well as depth to bottom of hole, and make aluminum � lathe insert deep enough that it nearly reaches the bottom, for maximum support during parting � operations. Use the diameter measurements in Illustration B, and adjust the lengths to fit � your crank.

�

�

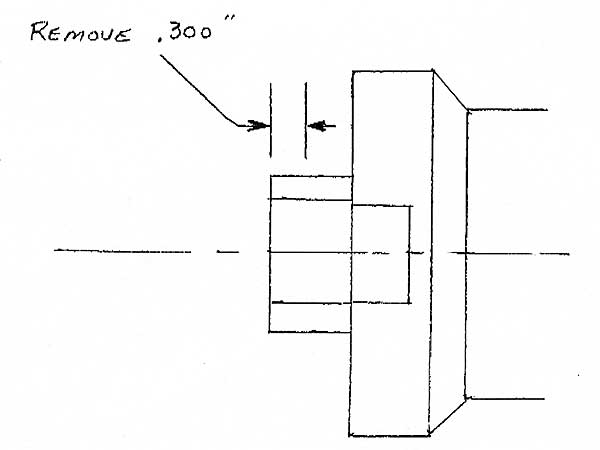

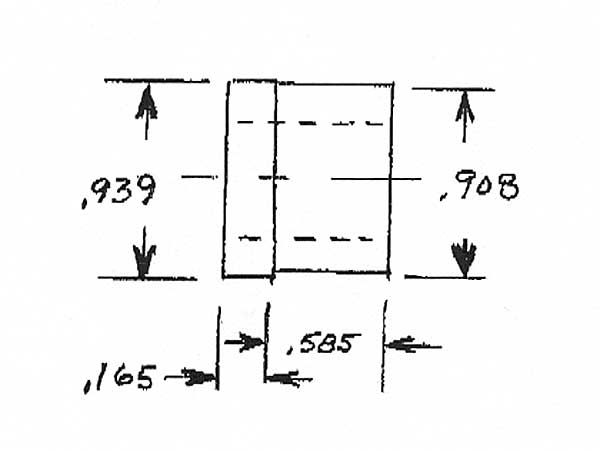

� Illustration B: Oilite Bronze Insert dimensions. The insert bore or i.d. is 0.592" for a � GM style T-5 transmission and 0.674" for a Ford V8 style T-5. For the aluminum lathe insert, � use the same diameter dimensions given here, but adjust (increase!) both length measurements � to fit the un-cut crank. Instead of drilling a bore, as on the bushing, place a countersink � that matches your tailstock taper at the precise center of the outside face of the insert.

�

Photo 3: Aluminum lathe adapter positioned in pilot bearing bore

�

Photo 4: Cutting the crank with a parting tool

�

Photo 5: Modified crank (shown at left) and a stock crank (at right)

�

� Disclaimer: This page was researched and written by Dan Lagrou and Kurt Schley. Views expressed � are those of the authors, and are provided without warrantee or guarantee. Apply at your own risk.�

�

�

� Illustration B: Oilite Bronze Insert dimensions. The insert bore or i.d. is 0.592" for a � GM style T-5 transmission and 0.674" for a Ford V8 style T-5. For the aluminum lathe insert, � use the same diameter dimensions given here, but adjust (increase!) both length measurements � to fit the un-cut crank. Instead of drilling a bore, as on the bushing, place a countersink � that matches your tailstock taper at the precise center of the outside face of the insert.

�

Photo 3: Aluminum lathe adapter positioned in pilot bearing bore

�

Photo 4: Cutting the crank with a parting tool

�

Photo 5: Modified crank (shown at left) and a stock crank (at right)

�

� Disclaimer: This page was researched and written by Dan Lagrou and Kurt Schley. Views expressed � are those of the authors, and are provided without warrantee or guarantee. Apply at your own risk.�