�

�

�

�

�

�

�

� �

� by: Dan Masters�

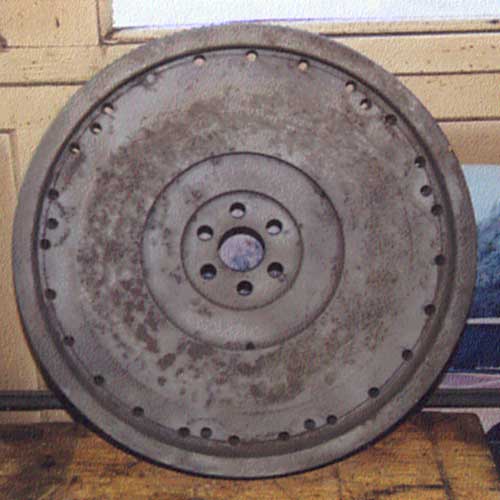

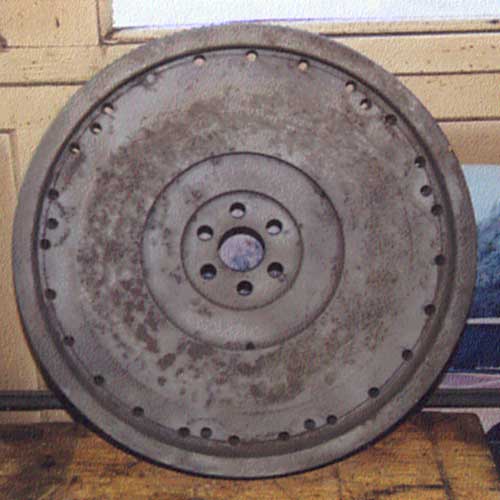

� Sure, we all know what a flywheel is - it's that heavy round thing � with teeth on it that fits on the end of the crankshaft, engages the � starter, and holds the clutch. Yeah, but what is a flywheel? �

� Basically, a flywheel is an energy storage device; you have to put � energy into it to make it spin, and you have to take energy out of � it to make it stop. In a vacuum (no wind resistance) and with perfect � bearings (no friction), a flywheel would continue to spin forever, � once put into motion, as there is nothing there to take energy out � of it.�

�

�

�

�

Introduction to Flywheels

� This article appeared in The British V8 Newsletter - Volume X, Issue 1 - January 2002�� by: Dan Masters�

� Sure, we all know what a flywheel is - it's that heavy round thing � with teeth on it that fits on the end of the crankshaft, engages the � starter, and holds the clutch. Yeah, but what is a flywheel? �

� Basically, a flywheel is an energy storage device; you have to put � energy into it to make it spin, and you have to take energy out of � it to make it stop. In a vacuum (no wind resistance) and with perfect � bearings (no friction), a flywheel would continue to spin forever, � once put into motion, as there is nothing there to take energy out � of it.�

�

�

Try this: Take your kids to the park, and put them on the merry-go-round. �

Gather up all the kids you can find, and their parents, and really �

load it up. Now, try to make it go around. Hard, isn't it? You may �

have to get help from your friends to get it really spinning. Once �

you get it started, try to stop it. Very difficult. When you do get �

it stopped, have everyone get off, and try again to get it started �

spinning. Without the extra weight (mass), you'll find that it's much �

easier to spin. Much easier to stop too.�

� Ok, so what does all this have to do with the flywheel in your car? � Consider the following two scenarios: �

� A) You're on your way home from the local home improvement store in � your pick-up truck, loaded down with lumber, cinder blocks, mortar, � etc. - more than you really should be carrying in that truck. You're � sitting at a stoplight, and when the light turns green, you try to � take off. With all that load in the truck, your poor little wheezer � engine just doesn't have the necessary oomph (torque) to pull you off � the line. In order to get moving, you have to really rev the engine � up to get it into its maximum torque rpm range, and slip the clutch � until you're finally moving. In this situation, you could really use � all the help you can get in the form of stored energy from your � flywheel.�

� Here, you'd like to have the heaviest flywheel you can get - the � heavier the flywheel, the more stored energy.�

� B) You're running an F1 car, under the yellow, in the final laps of � the race, following the pace car at what seems to be an excruciatingly � slow speed. When the flag goes to green, you want to get off the line � as fast as you can, out accelerating your competition. You have your � car in the proper gear to put the engine in the rpm range for maximum � torque, you have plenty of torque, and your car weighs next to nothing. � In this case, you do not want to spend any of your engine's precious � energy spinning up a heavy flywheel. You want all of that energy � directed to the rear wheels. A heavy flywheel here would be an � unnecessary burden. In fact, in this case, no flywheel at all would be � the preferred condition.�

��

�

� This then defines the prime criteria for flywheel weight considerations:�

� The LIGHTER the car, and/or the MORE TORQUE the engine produces, the LIGHTER � the flywheel needs to be.�

� The HEAVIER the car, and/or the LESS TORQUE the engine produces, the HEAVIER � the flywheel needs to be. �

� The flywheel also performs another function as well, one of smoothing the � engine's power pulses. As the engine turns, each cylinder goes through two � distinct phases - the compression stroke and the power stroke. On the power � stroke, the piston is driving the crankshaft. On the compression stroke, � the crankshaft is driving the piston. Thus, for every other revolution, � the crank alternates between "being twisted" and "twisting." The flywheel � absorbs energy on the "being twisted" phase, and then returns the energy � on the "twisting" phase, helping to smooth the engine pulsations. On a � single cylinder engine, this pulse damping is of significance. On a one � hundred cylinder engine, the pulses would be distributed so evenly that � the flywheel damping would not be needed. For this reason, a heavy flywheel � would be of less benefit to a V8 than it would be to a four cylinder engine.�

� The damping effect of the flywheel is also assisted by the damping action � of the harmonic balancer. In addition to the "flywheel" effect of the � relatively heavy damper, the elastic material between the inner and outer � portion of the harmonic balancer adds to the smoothing effect. This elastic � material absorbs some of the "being twisted" forces, and gives back during � the "twisting" phase. �

� So, what is a good weight for a flywheel in a British V8 conversion? Well, � most of the British cars we're concerned with here weigh around 2500 pounds � or less. That's relatively light weight, as cars go. If the V8 engine we're � installing doesn't have pretty good torque, we wouldn't be putting in � the car in the first place, so we can count on good torque values. Looking � through the various flywheel vender catalogs, we find flywheel weights � ranging from 15 to 50 pounds.�

�

�

�

� Ok, so what does all this have to do with the flywheel in your car? � Consider the following two scenarios: �

� A) You're on your way home from the local home improvement store in � your pick-up truck, loaded down with lumber, cinder blocks, mortar, � etc. - more than you really should be carrying in that truck. You're � sitting at a stoplight, and when the light turns green, you try to � take off. With all that load in the truck, your poor little wheezer � engine just doesn't have the necessary oomph (torque) to pull you off � the line. In order to get moving, you have to really rev the engine � up to get it into its maximum torque rpm range, and slip the clutch � until you're finally moving. In this situation, you could really use � all the help you can get in the form of stored energy from your � flywheel.�

� Here, you'd like to have the heaviest flywheel you can get - the � heavier the flywheel, the more stored energy.�

� B) You're running an F1 car, under the yellow, in the final laps of � the race, following the pace car at what seems to be an excruciatingly � slow speed. When the flag goes to green, you want to get off the line � as fast as you can, out accelerating your competition. You have your � car in the proper gear to put the engine in the rpm range for maximum � torque, you have plenty of torque, and your car weighs next to nothing. � In this case, you do not want to spend any of your engine's precious � energy spinning up a heavy flywheel. You want all of that energy � directed to the rear wheels. A heavy flywheel here would be an � unnecessary burden. In fact, in this case, no flywheel at all would be � the preferred condition.�

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

� This then defines the prime criteria for flywheel weight considerations:�

� The LIGHTER the car, and/or the MORE TORQUE the engine produces, the LIGHTER � the flywheel needs to be.�

� The HEAVIER the car, and/or the LESS TORQUE the engine produces, the HEAVIER � the flywheel needs to be. �

� The flywheel also performs another function as well, one of smoothing the � engine's power pulses. As the engine turns, each cylinder goes through two � distinct phases - the compression stroke and the power stroke. On the power � stroke, the piston is driving the crankshaft. On the compression stroke, � the crankshaft is driving the piston. Thus, for every other revolution, � the crank alternates between "being twisted" and "twisting." The flywheel � absorbs energy on the "being twisted" phase, and then returns the energy � on the "twisting" phase, helping to smooth the engine pulsations. On a � single cylinder engine, this pulse damping is of significance. On a one � hundred cylinder engine, the pulses would be distributed so evenly that � the flywheel damping would not be needed. For this reason, a heavy flywheel � would be of less benefit to a V8 than it would be to a four cylinder engine.�

� The damping effect of the flywheel is also assisted by the damping action � of the harmonic balancer. In addition to the "flywheel" effect of the � relatively heavy damper, the elastic material between the inner and outer � portion of the harmonic balancer adds to the smoothing effect. This elastic � material absorbs some of the "being twisted" forces, and gives back during � the "twisting" phase. �

� So, what is a good weight for a flywheel in a British V8 conversion? Well, � most of the British cars we're concerned with here weigh around 2500 pounds � or less. That's relatively light weight, as cars go. If the V8 engine we're � installing doesn't have pretty good torque, we wouldn't be putting in � the car in the first place, so we can count on good torque values. Looking � through the various flywheel vender catalogs, we find flywheel weights � ranging from 15 to 50 pounds.�

�

�

Ford Motor Company uses a 40 pound flywheel in their stock cars equipped �

with a 302ci V8. For their high performance crate engine, with torque values �

around 350lbft, they supply 27 pound flywheels. Generally, they expect �

these engines to be put into cars weighing over 3000 pounds, so the 27 �

pound figure would seem to be the upper limit for our applications, assuming �

a fairly low torque motor.�

� For a really hot engine, with stump pulling torque, a 15 pound flywheel � would be about right. Ted Lathrop is running a 15 pound flywheel in his � 350 Chevy powered TR6, and it feels to me to be just about right. His car � weighs less than 2500 pounds, and that engine should produce in excess of � 350lbft of torque. I have driven his car, and it is just about perfect. � Believe me, getting off the line is NO PROBLEM! Nor is there any significant � vibration. For lightly-modified BOP/Rover 215ci engines, which are quite � often used in MGB-V8 swaps, perhaps a 22 pounder would be more appropriate. �

� That heavy round thing with teeth on it isn't the only flywheel you have on � your car - you have four more, one on each corner of your car! Your tires � and wheels are also flywheels. Just like all flywheels, the heavier the � tire/wheel combo, the harder it is to get it spinning, and the harder it � is to get it to stop. Unlike the engine flywheel, though, there is NO purpose � to having extra weight on the tires and wheels. The ideal weight here is ZERO! �

� Besides the flywheel effect, extra weight here is just that much more mass � to get moving off the line, and that much more mass to stop. Not only does � the weight effect acceleration and braking, wheel and tire weight has a � tremendous impact on handling as well. The heavier the tire/wheel combo, � the harder it is for the suspension system to control the tire/wheel movement, � and the harder it is to keep the tire in correct contact with the road. There � is, then, a triple whammy to pay for extra weight on your tires and wheels. � Ample justification, I think, to spring the big bucks on a set of super � lightweight aluminum or magnesium wheels! �

� Additional Note: (added with internet publication in March 2007.) Early in � this article Dan suggested an experiment where you spin neighborhood kids on � a merry-go-round. While you're playing with the kids, why not take the opportunity � to make an additional observation and also teach the kids a fun, interesting and � relevant scientific principal? Have the kids sit near the center of the merry-go-round, � and you'll note that it's relatively easy to spin. Have them move to the outer edge, � and it gets harder to spin. Amazingly, if the kids move outward on the merry-go-round � as it spins the merry-go-round will actually slow down, and if they move inward it � will actually speed up (in terms of RPM). The part of this experiment that's � relevant to flywheels is that a spinning merry-go-round with kids concentrated around � its outer edges actually has significantly more rotational inertia than one with kids � evenly distributed over its surface. �

�

�

�

� For a really hot engine, with stump pulling torque, a 15 pound flywheel � would be about right. Ted Lathrop is running a 15 pound flywheel in his � 350 Chevy powered TR6, and it feels to me to be just about right. His car � weighs less than 2500 pounds, and that engine should produce in excess of � 350lbft of torque. I have driven his car, and it is just about perfect. � Believe me, getting off the line is NO PROBLEM! Nor is there any significant � vibration. For lightly-modified BOP/Rover 215ci engines, which are quite � often used in MGB-V8 swaps, perhaps a 22 pounder would be more appropriate. �

� That heavy round thing with teeth on it isn't the only flywheel you have on � your car - you have four more, one on each corner of your car! Your tires � and wheels are also flywheels. Just like all flywheels, the heavier the � tire/wheel combo, the harder it is to get it spinning, and the harder it � is to get it to stop. Unlike the engine flywheel, though, there is NO purpose � to having extra weight on the tires and wheels. The ideal weight here is ZERO! �

� Besides the flywheel effect, extra weight here is just that much more mass � to get moving off the line, and that much more mass to stop. Not only does � the weight effect acceleration and braking, wheel and tire weight has a � tremendous impact on handling as well. The heavier the tire/wheel combo, � the harder it is for the suspension system to control the tire/wheel movement, � and the harder it is to keep the tire in correct contact with the road. There � is, then, a triple whammy to pay for extra weight on your tires and wheels. � Ample justification, I think, to spring the big bucks on a set of super � lightweight aluminum or magnesium wheels! �

� Additional Note: (added with internet publication in March 2007.) Early in � this article Dan suggested an experiment where you spin neighborhood kids on � a merry-go-round. While you're playing with the kids, why not take the opportunity � to make an additional observation and also teach the kids a fun, interesting and � relevant scientific principal? Have the kids sit near the center of the merry-go-round, � and you'll note that it's relatively easy to spin. Have them move to the outer edge, � and it gets harder to spin. Amazingly, if the kids move outward on the merry-go-round � as it spins the merry-go-round will actually slow down, and if they move inward it � will actually speed up (in terms of RPM). The part of this experiment that's � relevant to flywheels is that a spinning merry-go-round with kids concentrated around � its outer edges actually has significantly more rotational inertia than one with kids � evenly distributed over its surface. �

�

�

Cutting to the chase, WEIGHT ISN'T THE ONLY CONSIDERATION WHEN COMPARING TWO FLYWHEELS. �

Diameter and distribution of mass relative to the axis are important too.�

A flywheel of relatively constant thickness from center to edge is far less�

effective at storing energy than a flywheel of equal weight that has a significant �

portion of its weight in a ring, outboard of the pressure plate, such as the �

"heavy" version of a Buick 215 flywheel. Another way to look at this is that cutting �

a pound of iron off the outer ring of a "heavy" Buick 215 flywheel will have more �

effect on performance than cutting two pounds off its face.�

� In addition to weight, anyone who makes or sells aftermarket performance flywheels � should also be able to tell you their respective "moments of inertia". � You should ask for this information... even though you're unlikely to get any � response but a blank stare, because we deserve to be given enough information by � parts vendors to make informed decisions. Weight alone is not enough information � to compare the performance of two flywheels if they have different cross-sections. �

� A fuller explanation of moment of inertia and related engineering principals � that apply to sports car design and performance is planned for a future issue of � the newsletter. �

� For more information on flywheels, please also see:

� Buick and Oldsmobile 215 Flywheels, by Kurt Schley (Vol 13, Iss 3)

� Buick/Olds 215 Flywheels, by Kurt Schley (Vol 12, Iss 1)�

� Disclaimer: This page was researched and written by Dan Masters. The "additional note" � was written by Curtis Jacobson. Views expressed are those of the authors, and are provided � without warrantee or guarantee. Apply at your own risk.�

�

�

� In addition to weight, anyone who makes or sells aftermarket performance flywheels � should also be able to tell you their respective "moments of inertia". � You should ask for this information... even though you're unlikely to get any � response but a blank stare, because we deserve to be given enough information by � parts vendors to make informed decisions. Weight alone is not enough information � to compare the performance of two flywheels if they have different cross-sections. �

� A fuller explanation of moment of inertia and related engineering principals � that apply to sports car design and performance is planned for a future issue of � the newsletter. �

� For more information on flywheels, please also see:

� Buick and Oldsmobile 215 Flywheels, by Kurt Schley (Vol 13, Iss 3)

� Buick/Olds 215 Flywheels, by Kurt Schley (Vol 12, Iss 1)�

� Disclaimer: This page was researched and written by Dan Masters. The "additional note" � was written by Curtis Jacobson. Views expressed are those of the authors, and are provided � without warrantee or guarantee. Apply at your own risk.�