�

�

�

�

Installing an In-Tank Fuel Pump

� as published in BritishV8 Magazine, Volume XVI Issue 2, October 2008�� by: Kelly Stevenson�

�

� In this article I'll describe how we installed an in-tank fuel-pump in my MGB. � The conversion of my 1978 MGB tourer to Ford 5.0L V8 power was initially � completed in May 2005. From the beginning, my conversion featured electronic � fuel injection, but the initial installation featured an external fuel pump. � That external fuel pump worked, but there are significant advantages to moving � the fuel pump into the fuel tank. Most modern OEM installations have in-tank � fuel pumps because they're quieter. They're also usually less susceptible to � supply problems when the fuel level is low and when fuel is sloshing around � during spirited driving.�

��

Obviously, fitting an in-tank fuel pump requires cutting into the tank. �

I suppose the traditional approach might be to cut and weld, but I believe �

it's best to start with a brand-new tank and to preserve its modern, �

corrosion-inhibiting coatings by soldering instead of by welding. �

�

After shopping around, I ordered a new "Spectra Premium" 1977-80 spec �

MGB fuel tank from an eBay merchant. The cost for the tank, including �

shipping, is about $189. (Note: 1977-80 fuel tanks are most easily �

identified by their short, straight-up, fuel-fuller inlet.) �

�

�

�

�

�

Editor's Notes: Spectra Premium Industries' MGB fuel tanks are made in Canada �

from U.S. Steel's "Ni-Terne" material. The annealed cold-rolled steel sheet is �

first processed to apply a thin flash coating of electrodeposited nickel, �

and then it's given a hot-dip lead-tin alloy coating. The nickel base coat �

gives Ni-Terne steel an extra measure of corrosion resistance compared to U.S. �

Steel's regular "Terne" steel sheet and also compared to traditional�

galvanizing, which isn't readily available anymore. It should also be pointed �

out that the Ni-Terne coating protects both interior and exterior surfaces of �

the fuel tank from surface corrosion. �

�

Spectra Premium tanks are available directly from Moss Motors and Moss distributors. �

Moss also sells British Motor Heritage brand fuel tanks, which are more�

appropriate to use for concours restorations because they're made in England �

on original MG tooling from plain steel sheet. British Motor Heritage fuel tanks �

arrive painted black. �

�

Painting the Spectra Premium fuel tanks isn't required or even recommended. �

Per Kelvin Dodd at Moss Motors, for best paint adhesion you must clean the �

tank very, very carefully to remove the oily film that covers it. �

�

Notice: we have not measured or compared a Spectra Premium MGB fuel tank to�

determine if they provide the same or more mounting depth for an in-tank fuel �

pump as compared to original OEM or other aftermarket MGB fuel tanks. You should �

measure before cutting... �

�

�

�

�

After the flange is soldered in, the module just drops in... but that's not the end of the job.

�

�

What about the fuel pump? I selected a modular fuel pump from a 1999 Chevrolet �

Malibu. This fuel pump is convenient to use because it mates to a relatively �

simple round flange in the horizontal top surface of a fuel tank. The Malibu �

fuel pump module has more features than I chose to use - specifically it has �

a built-in fuel level sensor. I won't be using this feature, so I removed the �

float. I believe this pump's flow capacity is about 30 gallons per hour. �

�

The Malibu fuel pump produces 60 psi. That's a lot more than I needed or wanted, �

(probably too much for Ford's OEM fuel pressure regulator), but I'd already �

invested in a Kirban (aftermarket) adjustable fuel pressure regulator which is �

easily set to the appropriate 38-39 psi for my fuel injectors. �

�

Actually, the fuel pump I used came with a complete Malibu fuel tank - from �

the junk yard. The reason to start with a junk yard fuel pump is that you �

need to cut the mounting flange from a donor tank. We used a pneumatic �

reciprocating saw to cut out the flange. Once removed, we neatly marked a �

circle around the flange, took it to a friend's shop, and used his belt sander �

to trim the flange down to that marked line. This left a round flange lip that �

looked good. �

�

The top surface of an MGB fuel tank has embossed ribs, and we decided to �

center the new fuel pump module over one of them. This embossment provided us �

with a challenge, but we met it by soldering spacers to the tank to create a �

flat mating plane. Specifically, we soldered two quarter-inch thick steel �

plates to level the mounting surface. The edges of the steel filler plates �

were radiused to match the tank's embossment. After the plates were soldered �

onto the tank, the flange was soldered onto the plates and tank rib. �

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

�

�

�

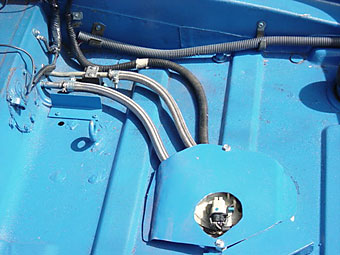

� As you can see in the photos, there are three ports on the Malibu fuel pump assembly.� The center port is a vapor vent. Since it's redundant with the vent port that the � MGB tank already has (next to the fuel filler inlet), we capped the pump's vapor port.� The other two ports are for inlet and for return. In some modern fuel injection systems � the fuel injectors are provided more pressurized fuel than they can possibly use, and � excess fuel is pumped right past the injector inlets and returned to the fuel tank. �

��

�

�

�

�

When it comes to wiring, we recommend that the fuel pump should be supplied from �

a relay. Pumps are very sensitive to voltage; they don't perform their best when �

they're operated at reduced power. A relay avoids this issue by eliminating �

electrical resistance and subsequent voltage-drop in the fuel pump circuit. Power �

is provided by a new lead, with an inline fuse, which is routed over from the battery.�

�

A "signal" is still required from the ignition switch to turn the relay "on" and �

"off". We used MG's original fuel pump lead for this purpose. �

�

The Malibu fuel pump can move a great deal of fuel at relatively high pressure, �

so in the event of an accident it needs to be turned "off" promptly and reliably. �

For this reason, we also installed a new Ford fuel cut-off inertia switch on the �

12V supply circuit. (Note: 1975-80 MGB's came with a white inertia switch on the �

extreme righthand end of the firewall, cabin-side, but we chose to replace and �

relocate this function on my car.)�

�

�

�

�

� A final aspect of the installation was fitment of a sheetmetal shield to protect � the module, fuel lines and wiring. My spare tire will still fit in the boot, over � top this metal shield.�

�� Disclaimer: This page was researched and written by Kelly Stevenson. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�

� Photos by Kelly Stevenson for British V8 Magazine. All rights reserved. �