�

�

�

�

�

�

� by: Dale Spooner�

� Unlike the BOP/Rover engines so popular with the British V8 conversion crowd, the clutch � actuation lever in a Ford engine is pulled forward for clutch operation. In the Ford donor � cars, this forward movement is accomplished by means of a cable arrangement. Although � possible, implementing a cable arrangement in an MGB can be difficult. One workable solution � to the reverse operation of the Ford clutch is to use a hydraulic throw-out bearing (HTOB), � exactly as used in many BOP/Rover applications. The major drawback to using the HTOB is � the inaccessibility of the HTOB for repairs should it become necessary (and it will, � sooner or later). �

�

�

�

�

�

Clutch Slave Cylinder for Ford V8�

Clutch Slave Cylinder for Ford V8

� This article appeared in The British V8 Newsletter - Volume XII, Issue 1 - January 2004�� by: Dale Spooner�

� Unlike the BOP/Rover engines so popular with the British V8 conversion crowd, the clutch � actuation lever in a Ford engine is pulled forward for clutch operation. In the Ford donor � cars, this forward movement is accomplished by means of a cable arrangement. Although � possible, implementing a cable arrangement in an MGB can be difficult. One workable solution � to the reverse operation of the Ford clutch is to use a hydraulic throw-out bearing (HTOB), � exactly as used in many BOP/Rover applications. The major drawback to using the HTOB is � the inaccessibility of the HTOB for repairs should it become necessary (and it will, � sooner or later). �

�

�

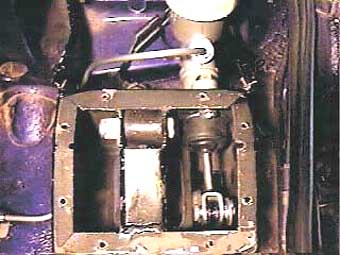

Feeling that ownership of a Ford powered MGB created difficulties enough on its own, I �

didn't want to have to deal with pulling the engine and/or transmission just to fix a �

leaky slave cylinder. After a little bit of research, I came up with the external "pusher" �

slave cylinder arrangement shown in the accompanying photos. �

��

�

�

�

�

�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

�

�

�

�

�

�

� I haven't yet figured out a clutch fork cover, but I'm still working on that.�

� Disclaimer: This page was researched and written by Dale Spooner. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�

�

�

�

�

�

�

�

�

�

� I haven't yet figured out a clutch fork cover, but I'm still working on that.�

� Disclaimer: This page was researched and written by Dale Spooner. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�