�

�

Not only is the T-50 a great transmission, you can use it to attract blonds. Can't do that with a Rover or T-5 box!�

In Defense of the Borg Warner T-50 Transmission

��

as published in MG V-8 Newsletter, Volume VI Issue 2, August 1998�

�

by: Jim Blackwood�

�

Well, I guess its all in what you're looking for, over the past several issues �

I've read a number of letters criticizing the stalwart T-50, and I think it �

should get equal time. While it's true that some of the criticisms have a �

basis of sorts, I hope to explain those and show the transmission's virtues. �

�

It has been said that first gear is useless. This is far from correct in all �

cases. To start with, there are two varieties of the transmission, �

distinguishable by the number of rings cut around the input shaft as I recall, �

and I have tried both in the MG. The preferred unit is the close ratio box �

which comes out of a V-8 Monza (Chevy of course). This makes for a very �

sporting and flexible powertrain as I will describe, but first, - ita concedo - �

were you to place the wide ratio box behind the V-8 there will be trouble. �

First gear becomes useless for anything short of a massive (but short) �

"Hole Shot", and it's too far between the other gears. It would end up being �

your "four speed with a "Granny Low". This wide ratio box is pretty common �

since it was used behind all four cylinder motors and in the S-10 trucks, �

whereas the performance oriented close ratio box, used in the lightweight �

Monza with V-8 power (265 and up) was sold primarily to enthusiasts. You have �

to wonder what they were thinking when they built this box, with its good �

ratios and a somewhat unusual shift pattern, but the answer has to be that �

Monzas were being used on road racing courses, and they wanted a suitable �

five speed. Since first gear was used for starting only (usually on Pit Row) �

the first-second shift was not critical, but the rest of the pattern had to �

be perfect. Ergo, the traditional "H" for the upper gears with first gear �

leading into the pattern... Putting reverse above first allowed a compact �

and fairly conventional layout of the gears and a very direct arrangement �

of shift rails for added strength and more reliable shifts. By the way, don't �

let the compact size of the case fool you, the gears and synchros are quite �

ample. (Ribbed thin-wall casting techniques were used to minimize size and �

weight.)�

�

To prevent accidental shifts into reverse from first gear, an ingeniously �

simple solution in the form of a lockout tab was provided and it works exactly �

as it was intended to, provided it hasn't been damaged by external forces. �

Any shift to reverse or first is against a reasonably strong spring detent �

which only a real ham-fisted driver could miss, and once in first a shift �

directly to reverse is impossible since you must first release then re-compress �

the detent. A shift from first to second is only a push away, and then you're �

in the "H". Since no road course would require you to downshift to first, �

fighting the detent while - in extremis - would not be a problem, and it is �

easily negotiated under less stressful conditions such as in the Pits (or �

at a stop sign, or red light). Of course, the "H" pattern, as used in the �

upper gears is the beloved of all drivers, and cannot easily be beat for ease �

of use, simplicity, etc. �

�

As I mentioned, this is a compact yet beefy transmission, with internal parts �

designed to take the abuse of an American V-8 in a lightweight car (by American �

standards) and designed for racing. As a result it uses needle bearings �

throughout, and lightweight, non-foaming, automatic transmission oil for a �

lubricant and coolant. As mentioned the gears are large, much larger than �

those seen in any of the boxes used in the MG's. The shift rails are also �

heavy and rigid, as is the shifter and the gates, and the synchros are massive �

by MG standards, having perhaps as much as three or four times the swept area. �

Here too, construction is of a typical, durable, effective and very reliable �

design identical in nearly all respects to the famous Muncie four-speed, with �

a hub, ring, two synchros, three blocker rings, and two large C-shaped keeper �

springs. They are very effective, and can withstand more abuse than nearly �

any driver can give them without blowing an elbow. HOWEVER, it must be �

remembered that you are dealing with a bit more mass than in a smaller �

transmission, and it takes just a bit longer to slow it down. The smallest �

bit of patience and planning in your shift points goes a very long way in �

alleviating the frustration of an impatient driver with perceived "hard shifts". �

The transmission does not shift hard. In fact it is a very easy shifting �

transmission if allowed to do its job. It will not, however, allow you to �

force it into grinding gears, and if you try it will abuse your tendons at �

least as badly as you abuse its synchros. �

�

As far as usable ratios are concerned, again, what are you looking for? �

A sporting ride, or a luxo-sedan? I hear talk about axle ratios like 2.70's �

and such with an overdrive, and I would he astounded if not for the realization �

that these cars are not intended to ever be driven hard. I'll explain why. �

With the stock 3.90 axle, the T-50's overdrive fifth gear, and 24 inch diameter �

tires a 5,000 RPM redline brings me up to 150 MPH with extremely good �

acceleration in all gears. Cruising at 75 MPH, the motor is ticking over at �

three grand and punches through the 100 mark in nothing flat. The car comes �

off the line like a rocket and the 1-2 shift comes on the other side of the �

intersection right after the hole shot, just as it should be. Above first, �

all ratios are well placed, and the car is tractable and docile, yet powerful. �

On flat land or downhill starts (and mild uphills) starting in second is not �

a problem, making in-town driving no more of a chore than with any four-speed, �

using the conventional shift pattern. Use of the stock sized tires, something �

better than two inches larger in diameter, would drop the cruising RPM @ 75 �

to less than 2800, and increase the top speed at redline (6000) to over 162MPH. �

�

I think we can all agree that this engine with a mild buildup is capable of �

supporting those numbers in this vehicle. The point is that you don't need �

to go any faster than that, but it sure is nice to have the acceleration. �

I don't honestly believe you'll gain very much fuel economy by dropping �

the engine speed another 500 or more RPM, as it's just loafing along anyway �

and with its short stroke runs very well at speed. If that's the goal, �

a better solution is fuel injection.�

| �

Enjoying this article? Our magazine is funded through the generous support of readers like you! � To contribute to our operating budget, please click here and follow the instructions. � (Suggested contribution is twenty bucks per year. Feel free to give more!)� |

�

Finally, in fitting the tranny to the MG, bellhousings are available from �

Phil Baker and from Dan LaGrou and a hydraulic throw-out bearing is a stock �

Chevy item. It is possible to use the stock crossmember with only minor �

alterations and a GM tranny mount. A little bending of the shifter will �

let it come through the floor in the right place, and after removal of the �

shifter extension the shaft can be ground, polished, painted, (chromed if �

you like) and a custom shifter fashioned for the top, allowing you to �

further individualize your car (or you can buy a knob). BTW, the pattern �

is very tight and precise when set up this way. �

�

So why the bad rap? I think a few people have tried the wide ratio boxes, �

with the (now) obvious resulting disappointment. If you get the right one �

though, it's a whole new story. Best of' all, they're dirt cheap. I believe �

I bought one for $100 and the other for $80, and the good one was the �

cheaper one. So try adding this to your bag of tricks. You'll be glad �

you did. �

�

Editor Kurt Schley added this note: The first transmission I had in my �

MG V-8 was a T-50 which I was unhappy with because of the unusable first �

gear and the unusual reverse gear shift position. I unconsciously shifted �

into reverse, thinking I was in first, several times and almost ended �

up as a hood ornament on the car behind me. Two years ago I switched to �

a T-5. After reading Jim's excellent article, I now realize that I had �

the wide ratio 6-cylinder box and that the reverse detent was not working �

on mine. To the T-50 transmission, I offer my apologies for all the bad �

things I said about you! Jim is also correct in stating that the T-50 is �

inexpensive. The last three I have seen at swap meets were all less than $150.�

�

�

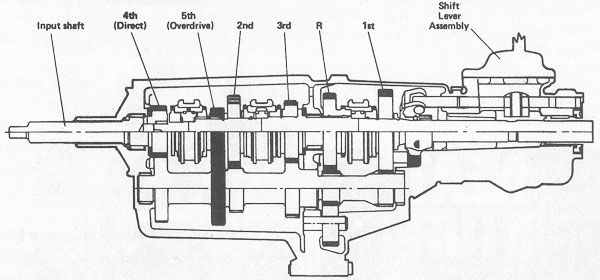

SPECIFICATIONS AND DESIGN FEATURES OF THE

BORG-WARNER T50 FIVE-SPEED MANUAL TRANSMISSION

�

�

The T50 is a five-speed manual transmission of a floor-shift type, fully synchronized �

in all forward speeds. It features a single rail shifter with shifting mechanisms �

totally enclosed. �

�

It is end loaded, allowing use of an oval case for greater strength. It is designed �

to be interchangeable (with minimal adjustments) with current production manual �

transmissions of similar capacity. �

�

Gear ratios (can be modified to customer requirements):�

| Vehicle Application: | 1st | 2nd | 3rd | 4th | 5th | REV |

| Overdrive top (smaller engines) | 3.41 | 2.08 | 1.40 | 1.00 | 0.80 | 3.36 |

| Overdrive top (larger engines) | 3.10 | 1.89 | 1.27 | 1.00 | 0.84 | 3.06 |

| Direct top | 3.49 | 2.48 | 1.83 | 1.37 | 1.00 | 3.49 |

�

| Efficiency: | |

| 1st gear | 95.2% |

| 2nd gear | 96.5% |

| 3rd gear | 96.3% |

| 4th gear | 99.0% |

| 5th gear | 96.5% |

�

Case and extension housing: Die-cast aluminum. �

�

Weight: 65 pounds. �

�

Gears: Helical throughout, including reverse; constant mesh reverse. �

�

Operating temperature: -30°F to 250°F with current seals and the specified �

lubricant; to 275°F with higher temperature seal material. �

�

Synchronizer capacity: Consistent with a 205 pounds/feet passenger car �

application. Larger 1-2 synchronizer is available. �

�

Oil retention: Dynamic oil seals are provided. Use of room temperature �

vulcanizing (RTV) static seal material eliminates oil leakage and provides �

metal-to-metal fit of mating parts. �

�

Shift travel: Adaptable to customer requirements.�

�

Other features: Live countershaft, blocker-type synchronizers, needle �

bearing support throughout and needle thrust bearings on the main shaft. �

� Notice:

� With digitization of this article in 2008, Jim Blackwood suggested the following additional comment:

� "I feel the torque limit of 205 ft/lbs should be strictly adhered to!"�

� �

� Disclaimer: This page was researched and written by Jim Blackwood. Views expressed � are those of the author, and are provided without warrantee or guarantee. Apply at your � own risk.�